Metal Epoxy Putty Market Research, 2032

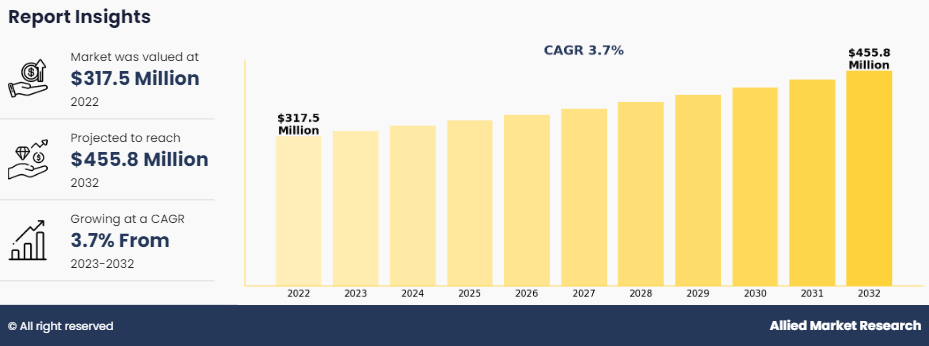

The global metal epoxy putty market size was valued at $317.5 million in 2022, and is projected to reach $455.8 million by 2032, growing at a CAGR of 3.7% from 2023 to 2032. Metal epoxy putty is a resilient and adaptable substance utilized for mending and bonding metal surfaces. Comprising two components, a resin and a hardener, when mixed together, it transforms into a strong, long-lasting adhesive. Known for its remarkable potency, it effectively adheres to various metals such as steel, aluminum, iron, and brass. This versatility makes it suitable for fixing leaks, cracks, and holes in metal components. In addition, it serves in reconstructing small metal parts, filling dents or seams, and renovating worn or damaged surfaces.

Highlights of the Report

- The report provides exclusive and comprehensive analysis of the global metal epoxy putty market trends along with the market forecast.

- The report elucidates the metal epoxy putty market opportunity along with key drivers, and restraints of the market. It is a compilation of detailed information, inputs from industry participants and industry experts across the value chain, and quantitative and qualitative assessment by industry analysts.

- Porter’s five forces analysis helps to analyze the potential of the buyers & suppliers and the competitive scenario of the market for strategy building.

- The report entailing the market analysis maps the qualitative sway of various industry factors on market segments and geographies.

- The data in this report aims on market dynamics, trends, and developments impacting the market growth.

The composition and curing process of the epoxy putty enable it to withstand substantial pressure and harsh conditions, ensuring sustainable repairs and renovations for a wide range of metal applications. With its reliability and adaptability, metal epoxy putty stands out as a reliable solution for maintenance, restoration, and enhancement of metal structures and components.

Epoxy putty is a versatile material with applications spanning ship building, car repair, and refurbishment industries. Its adaptability makes it a popular choice in commercial settings, workshops, homes, and gardens. One of the notable strengths is its strength to adhere to wooden surfaces, making it ideal for filling gaps with ease of sanding, drilling, and painting for a flawless finish. Its water-resistant nature proves invaluable in repairing leaking pipes, offering a durable fix. This widespread utility highlights its indispensability in maintenance and repair activities across various environments, strengthening its status as a preferred choice for professionals and DIY enthusiasts. The global metal epoxy putty market is expected to witness significant growth during the forecast period. This is attributed due to increase in the in shipbuilding activities. In addition, the surge in the demand for new ships and vessels to meet the expanding maritime trade, upgrades in naval fleets, and the flourishing leisure boating sector, propels the market growth.

Furthermore, metal epoxy putty industry, known for its resilience, water resistance, and strong adhesion to metal surfaces, holds a crucial position in both ship construction and maintenance. Its extensive use in repairing, filling, and sealing metal components of ships ensures enhanced durability and protection against the harsh marine environment. In addition, rise in shipbuilding activities has led to the upsurge in the demand for high-quality metal epoxy putty, thereby fueling market growth. Manufacturers are expected to capitalize on this trend by leveraging technological advancements to enhance product formulations, with a focus on attributes such as curing time, strength, and corrosion resistance. This growth trajectory highlights the indispensable role of metal epoxy putty in the maritime industry, emphasizing its significance in enhancing the durability and longevity of marine vessels and highlighting its crucial contribution to the rising global shipbuilding industry.

The market landscape is experiencing a notable shift propelled by the introduction of innovative materials aimed at replacing traditional metal epoxy putty. Advanced polymers and composite materials are swiftly gaining traction, offering comparable or superior performance across various applications. This transition is not merely regarding material substitution but capitalizing on the unique properties of these alternatives, such as enhanced durability, flexibility, corrosion resistance, and potentially lower costs. Industries across automotive to aerospace are embracing these materials to meet evolving demands.

This trend highlights a broader movement towards materials science innovation, prioritizing the development of smarter, more sustainable solutions that outshine conventional options in efficiency, longevity, and environmental impact. As these advanced materials continue to advance and their advantages become more widely acknowledged, they pose a competitive challenge to metal epoxy putty industry, potentially reshaping market dynamics and establishing new benchmarks for performance and sustainability in industrial applications.

The surge in the automotive and manufacturing sectors has led to the upsurge in the demand for durable, efficient, and versatile materials. Metal epoxy putty stands out for its durability, ease of application, and versatility, making it an ideal solution to meet this demand. It plays a crucial role in repairing, bonding, and sealing metal parts, which are essential processes in both automotive and manufacturing processes. Its exceptional properties, such as resistance to chemicals, heat, and electrical currents, make it indispensable in machinery and vehicle maintenance and assembly.

Furthermore, the continuous hunt for innovation and quality in automotive and manufacturing products further highlights the importance of reliable materials such as metal epoxy putty. As these industries aim for excellence and longevity in their outputs, the reliance on metal epoxy putty is set to increase, offering lucrative opportunities for growth and advancement in its market. This associated relationship demonstrates how the progress of automotive and manufacturing industries simultaneously drives the expansion and refinement of the metal epoxy putty market growth.

Competitive Landscape

The key players profiled in this report are ITW, 3M, Dampney Company Inc., Henkel, Belzona, Jenolite, AW Chesterton Co., SealXpert Products, Aremco, and United Resin Corporation. Acquisition and strategic partnership are common strategies followed by major market players. For instance, in October 2021, Polytec PT GmbH and CollTech R&D Center GmbH have recently announced a strategic merger, signaling a significant step towards optimizing their combined capabilities. Through this merger, Polytec PT aims to leverage the synergies between the two companies, enhancing their capacity to deliver quality products and services. Under the Polytec PT umbrella, CollTech's renowned UV-curing adhesives and other specialized offerings will now be integrated into the product portfolio. Notably, the production facility in Maxdorf continues operations under Polytec PT, ensuring continuity and stability for customers. Importantly, both companies' teams united, offering customers enhanced expertise and support.

This merger promises customers an expanded array of high-performance adhesives, such as electrically and thermally conductive variants, epoxy adhesives, potting compounds, thermal interface materials, and a comprehensive range of UV-curing products and fast-curing thermal epoxies. With a broader selection of innovative solutions at their disposal, customers can expect enhanced value and efficiency in their operations. This collaboration highlights Polytec PT's commitment to driving innovation and meeting the evolving needs of its clientele.

Segment Analysis

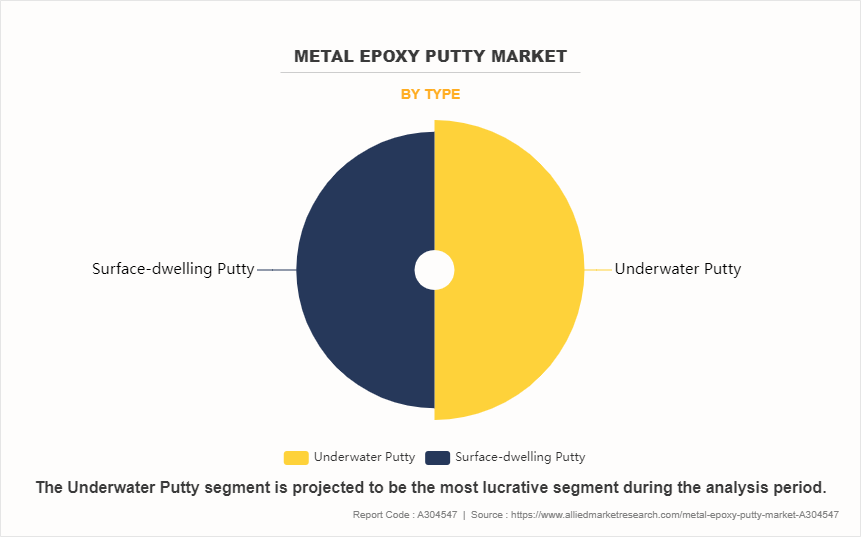

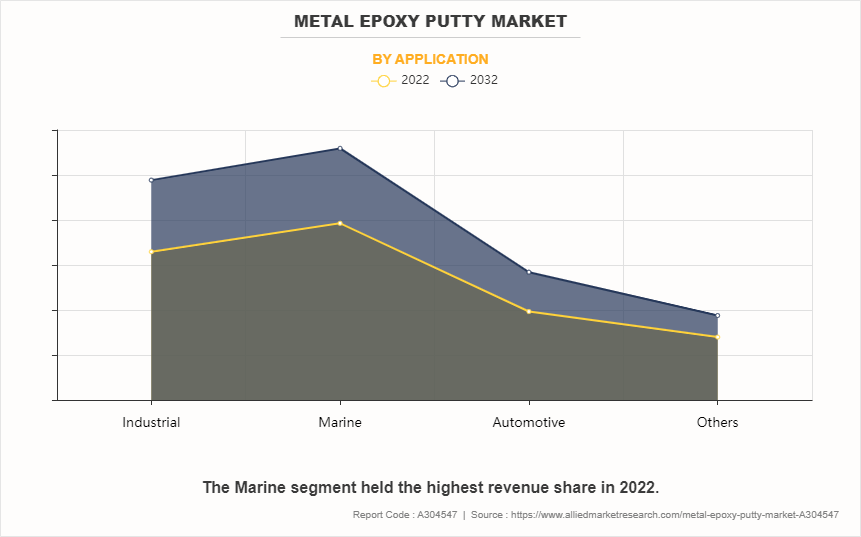

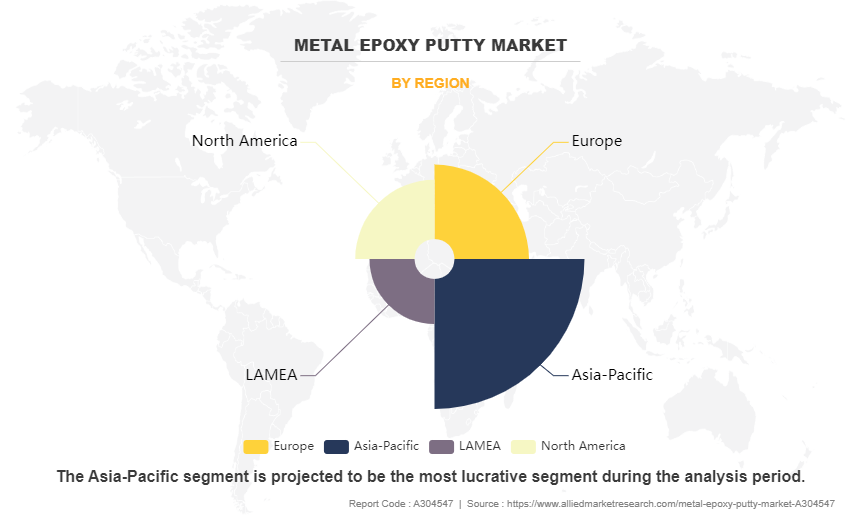

The metal epoxy putty market share is segmented into type, application, and region. Based on type, the market is divided into underwater putty, and surface-dwelling putty. By application, the market is classified into industrial, marine, automotive, and others. By region, the market is analyzed across North America, Europe, Asia-Pacific, and LAMEA.

The metal epoxy putty market is segmented into Type and Application.

On the basis of type, the underwater putty segment dominated the global metal epoxy putty market in 2022. The increase in the demand for underwater putty within the metal epoxy putty market is propelled by its unique attributes and diverse applications, establishing it as a preferred solution for underwater repair and maintenance activities. Known for its exceptional adhesion to metal surfaces even in submerged conditions, underwater putty has become indispensable for industries and professionals operating in aquatic environments. Its reputation for reliability and longevity further cements its widespread adoption across various sectors. Manufacturers and suppliers are prioritizing continuous improvements in the quality and formulation of underwater putty products to meet the evolving demand and maintain their competitive edge in the market. With a significant market share and promising growth prospects, the underwater putty segment remains a key driver behind the overall expansion of the metal epoxy putty market, reflecting its crucial role in catering to the evolving demands of industries reliant on effective underwater solutions.

By application, the marine industry segment dominated the global metal epoxy putty market in 2022. Metal epoxy putty is highly preferred in marine applications due to its proven efficacy and reliability in addressing specific challenges within the industry. With the marine sector's wide-ranging demands spanning from repair and maintenance to construction and fabrication, this material emerges as a versatile solution capable of meeting diverse demands. Its ability to adhere effectively to various metal surfaces and withstand the rigors of harsh marine environments positions it as an indispensable asset for shipbuilding, vessel maintenance, and offshore infrastructure development. The notable dominance of the marine industry segment in the metal epoxy putty market highlights the substantial demand fueled by ongoing maritime activities globally and surging development of steel reinforced infrastructure. As maritime operations continue to expand and adapt to evolving needs, the reliance on metal epoxy putty is anticipated to persist, solidifying its crucial role as a fundamental component in the marine industry's arsenal of maintenance and repair solutions.

By region, Asia Pacific dominated the metal epoxy putty market in 2022. This is attributed to several key factors driving demand. Rapid industrialization, coupled with extensive infrastructure development projects, has led to surge in the demand for metal epoxy putty. The escalating activities in shipbuilding and the thriving automotive sector have further propelled this demand, highlighting the product's versatility in repairing, bonding, and shaping various metal components. Across manufacturing, construction, and maintenance sectors, metal epoxy putty has become indispensable. The dynamic economic landscape of the Asia-Pacific, supported by substantial investments in research and development, has contributed significantly to market expansion. Manufacturers and suppliers are experiencing a notable uptick in demand, translating into substantial revenue generation. Continuous innovation and a proactive approach to address evolving market requirements in steel reinforced infrastructure are further fueling the growth trajectory of the metal epoxy putty market in the region. With these factors the Asia-Pacific metal epoxy putty market forecast is poised for sustained growth and poised to maintain its dominance in the foreseeable future.

Key Benefits For Stakeholders

- This report provides a quantitative analysis of the market segments, current trends, estimations, and dynamics of the metal epoxy putty market analysis from 2022 to 2032 to identify the prevailing in the market opportunities.

- The market research is offered along with information related to key drivers, restraints, and opportunities.

- Porter's five forces analysis highlights the potency of buyers and suppliers to enable stakeholders make profit-oriented business decisions and strengthen their supplier-buyer network.

- In-depth analysis of the metal epoxy putty market segmentation assists to determine the prevailing market opportunities.

- Major countries in each region are mapped according to their revenue contribution to the global market.

- Market player positioning facilitates benchmarking and provides a clear understanding of the present position of the market players.

- The report includes the analysis of the regional as well as global metal epoxy putty market trends, key players, market segments, application areas, and market growth strategies.

Metal Epoxy Putty Market Report Highlights

| Aspects | Details |

| Market Size By 2032 | USD 455.8 million |

| Growth Rate | CAGR of 3.7% |

| Forecast period | 2022 - 2032 |

| Report Pages | 295 |

| By Type |

|

| By Application |

|

| By Region |

|

| Key Market Players | AW Chesterton Co., 3M, Belzona, SealXpert Products, Aremco, Jenolite, United Resin Corporation, Dampney Company Inc., ITW, Henkel |

The metal epoxy putty market is expected to grow due to its versatile applications across various industries. Known for its bonding properties and resistance to heat, chemicals, and corrosion, epoxy putty is extensively used in metal repairs, maintenance, and construction.

The major growth strategies adopted by the metal epoxy putty market players are product launches and partnership agreements.

Asia-Pacific will provide more business opportunities for the global metal epoxy putty market in the future.

Aerox, Technodinamika, Rockwell Collins, Inc, Cobham plc, Diehl Stiftung & Co. KG, Aviation Oxygen Systems Inc, Adams Rite Aerospace Inc, Safran, Essex Industries, Inc, and Precise Flight, Inc. are the major players in the metal epoxy putty market.

The underwater putty sub-segment of the type segment acquired the maximum share of the global metal epoxy putty market in 2022.

Marine industries are the major customers in the global metal epoxy putty market.

The report provides an extensive qualitative and quantitative analysis of the current trends and future estimations of the global metal epoxy putty market from 2022 to 2032 to determine the prevailing opportunities.

The industrial sector's stringent requirements for durable and high-performance repair materials fuel the adoption of metal epoxy putty. In addition, rise in focus on maintenance and refurbishment activities in industrial facilities to persist equipment lifespan contributes to the escalating demand for metal epoxy putty.

The metal epoxy putty market has witnessed significant growth owing to its versatile applications in various industries. Epoxy putty, known for its bonding properties and resistance to heat, chemicals, and corrosion, finds extensive use in metal repairs, maintenance, and construction.

Loading Table Of Content...

Loading Research Methodology...