Molded Foam Market Research, 2033

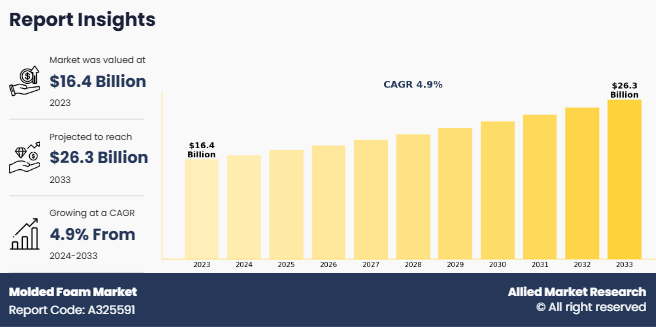

The global molded foam market size was valued at $16.4 billion in 2023, and is projected to reach $26.3 billion by 2033, growing at a CAGR of 4.9% from 2024 to 2033.

Introduction

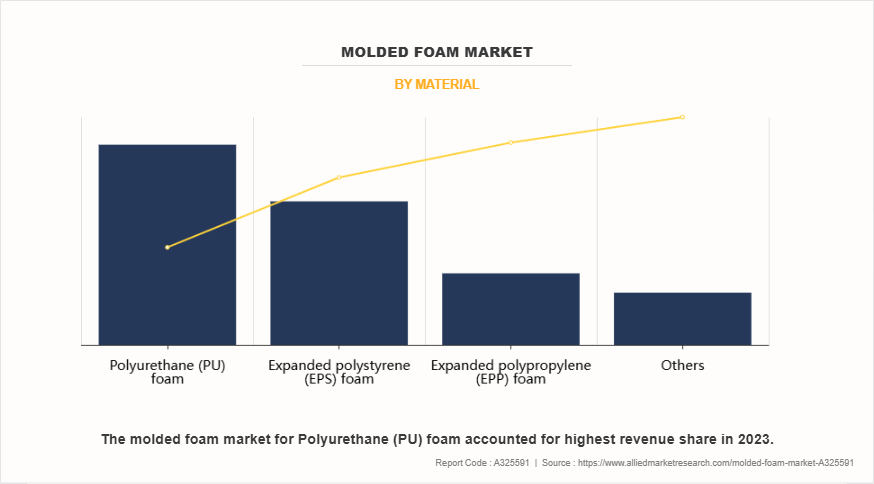

Molded foam is a lightweight, durable, and flexible material created by injecting liquid foam into a mold, where it expands and solidifies into a specific shape. This process allows for precise customization, making it ideal for applications in packaging, automotive seating, medical cushions, sports equipment, and protective gear. Molded foam is available in various types, including polyurethane (PU), expanded polystyrene (EPS), and expanded polypropylene (EPP), each offering unique properties such as shock absorption, thermal insulation, and resilience. Its ability to provide comfort, impact resistance, and design flexibility makes it a preferred choice in multiple industries.

Key Takeaways

- The global molded foam market is highly fragmented, with several players including Covestro AG, Sumitomo Chemical Co., Ltd., Momentive Performance Materials, Dow, BASF SE, Hennecke GmbH, Asahi Kasei Corporation, Huntsman Corporation, JSP Corporation, and Polymer Technologies, Inc.

- More than 4,765 product literatures, industry releases, annual reports, and other such documents of major industry participants along with authentic industry journals, trade associations' releases, and government websites have been reviewed for generating high-value industry insights.

- The study integrated high-quality data, expert opinions and analysis, and crucial independent perspectives. This research approach aims to provide a balanced view of global markets and molded foam market overview, assisting stakeholders in making informed decisions to achieve their most ambitious growth objectives.

- Molded foam market news and key industry trends are also included in the report.

Market Dynamics

The molded foam market is driven by the rising demand for lightweight and energy-efficient materials in industries such as automotive, packaging, and construction. The increasing adoption of molded foam in cushioning applications and thermal insulation further boosts market growth.

In the construction sector, molded foam materials, such as expanded polystyrene (EPS) and polyisocyanurate (polyiso), play a crucial role in enhancing building performance through effective insulation and soundproofing. These materials are integral to creating energy-efficient building envelopes by providing continuous insulation, reducing thermal bridging, and maintaining consistent indoor temperatures. For instance, EPS insulation offers features like continuous insulation, an airtight barrier component, and a weather-resistant barrier, all of which contribute to a building's energy efficiency.

The expansion of the packaging industry, driven by the rapid growth of e-commerce and global logistics, has significantly increased the demand for molded foam as a preferred protective packaging material. Molded foam is widely used in packaging due to its excellent cushioning, shock absorption, and lightweight properties, ensuring the safe transportation of fragile and high-value products such as electronics, medical devices, automotive components, and consumer goods. With the surge in online shopping, businesses are prioritizing protective and cost-effective packaging solutions to prevent product damage during shipping, reducing returns and enhancing customer satisfaction. Molded foam provides superior impact resistance, making it an ideal choice for securing delicate items against rough handling and transportation shocks.

Beyond e-commerce, molded foam is also gaining traction in industrial and food packaging applications. The automotive and electronics industries rely on molded foam inserts and trays for the secure transport of sensitive components, minimizing the risk of breakage and operational disruptions. In the food sector, molded foam containers offer excellent thermal insulation, helping to maintain the temperature of perishable items during transit, especially in cold chain logistics. The lightweight nature of molded foam further benefits logistics companies by reducing shipping costs and fuel consumption, contributing to overall supply chain efficiency. Additionally, molded foam products contribute to soundproofing by dampening noise transmission, thereby enhancing occupant comfort.

The growing emphasis on sustainable and energy-efficient construction practices has further propelled the demand for these materials, as they not only improve thermal performance but also support environmental goals by reducing energy consumption. Innovations in foam insulation, such as the development of biodegradable foams for structural insulated panels, are also contributing to more sustainable building practices. By incorporating molded foam insulation, builders can achieve higher energy efficiency standards, meet stringent building codes, and contribute to the overall sustainability of the built environment.

Additionally, the growing focus on sustainability is pushing manufacturers to develop eco-friendly molded foam alternatives, such as biodegradable and recyclable foam solutions. Companies are investing in innovative materials, including bio-based and compostable foam packaging, to align with increasing regulatory restrictions on plastic waste and consumer demand for environmentally responsible packaging. With the continuous rise in global trade, cross-border e-commerce, and supply chain expansions, the demand for molded foam in the packaging industry is expected to grow, driven by its unmatched protective qualities and adaptability across various applications. However, restraints include fluctuating raw material prices and stringent environmental regulations regarding foam disposal and recycling. Despite these challenges, opportunities lie in the development of sustainable and bio-based foam alternatives, along with advancements in manufacturing technologies that enhance product performance and cost-effectiveness.

Segments Overview

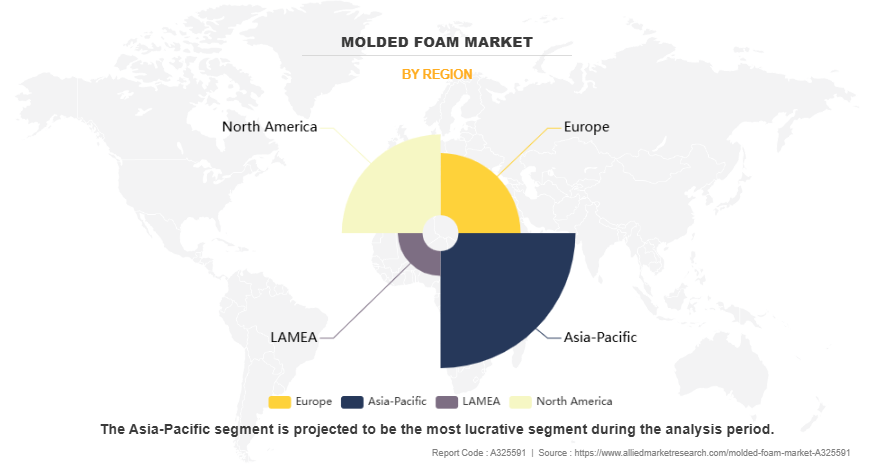

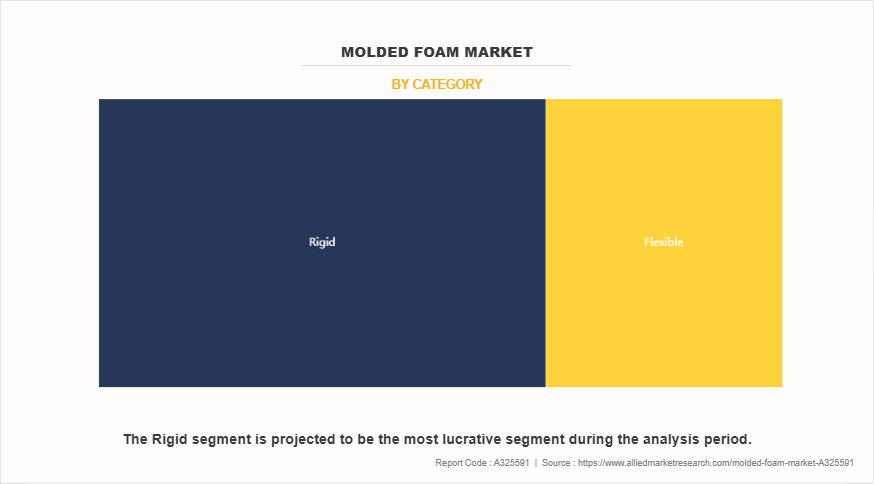

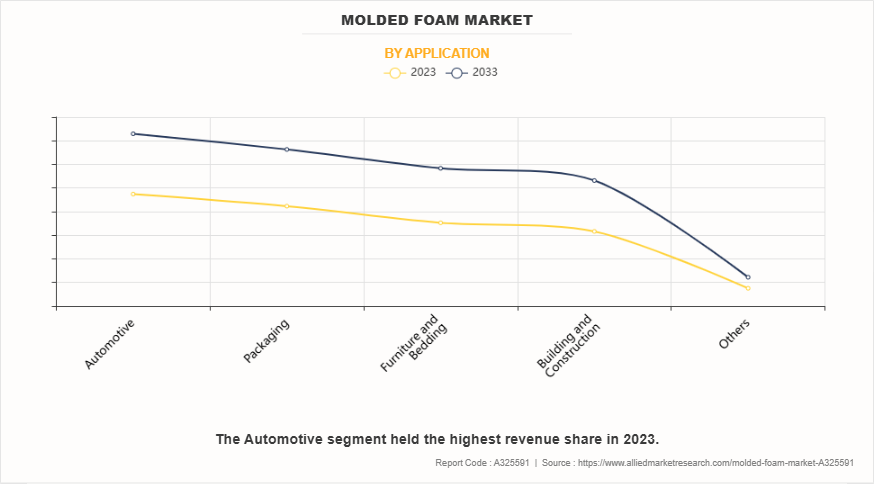

The molded foam market is segmented into material, category, application, and region. Based on material, the market is categorized into polyurethane (PU) foam, expanded polystyrene (EPS) foam, expanded polypropylene (EPP) foam, and others. By category, the molded foam market is classified into flexible and rigid. By application, the molded foam market is classified into automotive, packaging, furniture & bedding, building & construction, and others. Region wise, the molded foam market share is analyzed across North America, Europe, Asia-Pacific, and LAMEA.

Asia-Pacific was the highest revenue contributor, growing at a CAGR of 5.2%. The molded foam market in the region is witnessing steady growth, driven by its increasing use in automotive, packaging, furniture, and construction industries. Rapid industrialization, urbanization, and rising disposable incomes are fueling demand for lightweight, durable, and cost-effective materials, further propelling market expansion. China, Japan, India, and South Korea are key contributors to market growth, with China dominating due to its large manufacturing base and high consumption in packaging and automotive sectors. Expanded Polypropylene (EPP) and Expanded Polystyrene (EPS) are widely used, especially in protective packaging and automotive components, due to their superior impact resistance and recyclability. Sustainability concerns and government regulations on plastic waste are pushing manufacturers toward bio-based and recyclable molded foam solutions. The e-commerce boom is significantly increasing demand for protective packaging, further driving market expansion.

Competitive Analysis

The key players operating in the molded foam market are Covestro AG, Sumitomo Chemical Co., Ltd., Momentive Performance Materials, Dow, BASF SE, Hennecke GmbH, Asahi Kasei Corporation, Huntsman Corporation, JSP Corporation, and Polymer Technologies, Inc.

Key Benefits For Stakeholders

- This report provides a quantitative analysis of the market segments, current trends, estimations, and dynamics of the molded foam market analysis from 2023 to 2033 to identify the prevailing molded foam market opportunities.

- The market research is offered along with information related to key drivers, restraints, and opportunities.

- Porter's five forces analysis highlights the potency of buyers and suppliers to enable stakeholders make profit-oriented business decisions and strengthen their supplier-buyer network.

- In-depth analysis of the molded foam market segmentation assists to determine the prevailing market opportunities.

- Major countries in each region are mapped according to their revenue contribution to the global market.

- Market player positioning facilitates benchmarking and provides a clear understanding of the present position of the market players.

- The report includes the analysis of the regional as well as global molded foam market trends, key players, market segments, application areas, and market growth strategies.

Molded Foam Market Report Highlights

| Aspects | Details |

| Market Size By 2033 | USD 26.3 billion |

| Growth Rate | CAGR of 4.9% |

| Forecast period | 2023 - 2033 |

| Report Pages | 405 |

| By Material |

|

| By Category |

|

| By Application |

|

| By Region |

|

| Key Market Players | Momentive Performance Materials, JSP Corporation, Polymer Technologies, Inc., Hennecke GmbH, Asahi Kasei Corporation, Huntsman Corporation, BASF SE, Dow, Covestro AG., Sumitomo Chemical Co., Ltd. |

Analyst Review

According to the opinions of various CXOs of leading companies, the molded foam market is expected to witness an increase in demand during the forecast period. The molded foam market is experiencing significant growth, driven by several key factors. A primary driver is the increasing demand from the automotive industry, where manufacturers are focusing on reducing vehicle weight to improve fuel efficiency and meet stringent emission standards. Molded foam components are extensively used in various automotive parts to achieve these objectives. Additionally, the surge in e-commerce has bolstered the need for effective protective packaging solutions. Molded foam's excellent cushioning properties make it ideal for safeguarding products during transit, thereby driving its adoption in the packaging industry.

Innovations in foam manufacturing are significantly enhancing product performance and expanding application areas through advanced molding techniques and the development of sophisticated foam formulations. For instance, continuous foaming processes have been developed to produce foam through a series of connected vessels, allowing for more consistent and efficient production with reduced material waste. This method is particularly effective for creating high-quality, low-density foam. Additionally, the integration of nanotechnology into foam manufacturing has led to materials with enhanced structural integrity and flexibility. Modern techniques now incorporate nanomaterials to improve the mechanical properties of foams, resulting in products that are both lightweight and durable. Furthermore, the adoption of robotic 3D printing in foam manufacturing is enabling the creation of complex, lightweight structures. This innovative approach allows for precise control over foam architecture, facilitating the production of customized components for various industries, including aerospace and construction. These advancements not only improve the performance characteristics of foam products but also open new avenues for their application across diverse sectors, from automotive and aerospace to packaging and consumer goods.

The molded foam market is driven by the rising demand for lightweight and energy-efficient materials in industries such as automotive, packaging, and construction. The increasing adoption of molded foam in cushioning applications and thermal insulation further boosts market growth.

The key players operating in the molded foam market are Covestro AG, Sumitomo Chemical Co., Ltd., Momentive Performance Materials, Dow, BASF SE, Hennecke GmbH, Asahi Kasei Corporation, Huntsman Corporation, JSP Corporation, and Polymer Technologies, Inc.

The global molded foam market was valued at $16.4 billion in 2023, and is projected to reach $26.3 billion by 2033, growing at a CAGR of 4.9% from 2024 to 2033.

Asia-Pacific is the largest regional market for Molded Foam.

Automotive is the leading application of Molded Foam Market.

Loading Table Of Content...

Loading Research Methodology...