Global Molding Compounds Market Research, 2031

The global global molding compounds market size was valued at $10.10 billion in 2021, and is projected to reach $17.02 billion by 2031, growing at a CAGR of 5.5% from 2022 to 2031.

Molding compounds are composite materials that comprise epoxy resins, phenolic, silicas, pigments, polyester, and others. Molding compounds possess various properties such as it has high strength, tenacity, corrosion, heat resistance, and it is dimensionally stable owing to such functionalities it is extensively used in various end use industries such as electrical, automotive, electronics, industrial, manufacturing, and aerospace.

Molding compounds are widely used as substitute for metals in several end-use sectors such as building & construction and automotive, owing to their resistance to corrosion, lightweight, and better insulation property. In addition, factors such as growth in concentration of manufacturers, availability of feedstock at reduced prices, and arrival of local players have led manufacturers to offer molding compounds at low prices. These factors are responsible for growth of molding compounds in the market.

However, molding compounds have a high initial cost and careful design needs to make using molding compounds increases complexity, which creates problem in manufacturing sectors. In addition, molding compounds are industrial plastics, widely used in industrial sector and exposure to these compounds have adverse effects on health such as eye irritation, cough, throat infection, and skin irritation, which hampers the market growth. These factors are responsible for decline in growth of the molding compounds market.

On the contrary, increase in awareness regarding hygiene-related activities has led to growth of the packaging sector where molding compounds are widely used for manufacturing films & wraps and for packaging of a wide range of consumer goods. Moreover, increase in investments in building infrastructure in countries such as the U.S., China, Japan, Mexico, and India have led the building & construction sector to witness a significant growth where thermoset-based resins such as epoxy, and phenolic resin compounds are employed as insulating materials and cladding panels. These factors are predicted to contribute toward the global molding compound market growth and are anticipated to offer new opportunities in the global molding compounds market.

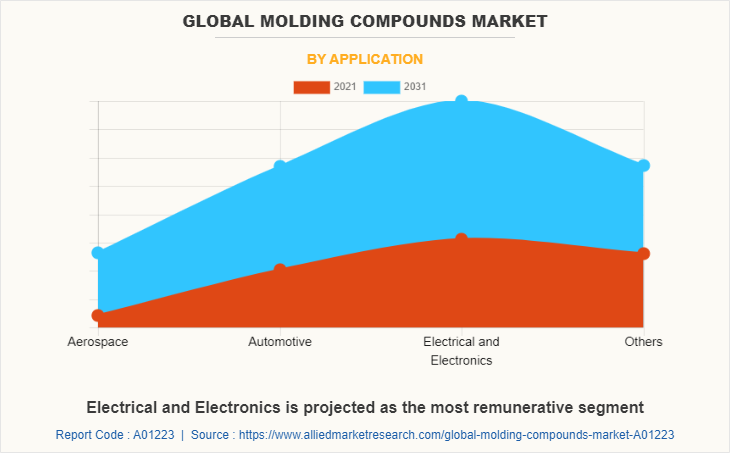

The molding compounds market is segmented on the basis of resin type, application, and region. On the basis of resin type, the market is categorized into phenolic, epoxy, polyester, and others. On the basis of application, the market is divided into electrical and electronics, aerospace, automotive, and others. Region-wise, the market is studied across North America, Europe, Asia-Pacific, and LAMEA.

In 2021, the phenolic segment was the largest revenue generator, and is anticipated to grow at a CAGR of 6.0% during the forecast period. Phenolic molding compounds exhibits heat, corrosion, and chemical resistant property and possess high dimensional stability. Such functionalities lead to its use in automotive, in small engines, electrical components, and other end use sectors. It is mainly used as an insulator in electrical components, in electrical vehicles, and other electrical instruments.

By application, the electrical segment dominated the global market in 2021, and is anticipated to grow at a CAGR of 6.1% during forecast period. This is attributed to the fact that molding compounds account for around 30% of the total production of molding compounds and are extremely versatile and cost-effective molding compounds used in electrical, manufacturing industry, automotive, and other industries where high temperature operations are carried out. These factors propel growth of the electrical segment in the global molding compounds market.

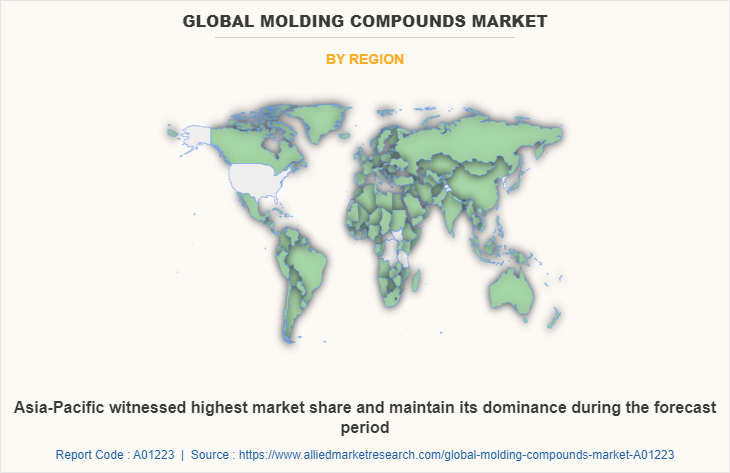

The Asia-Pacific molding compounds market size is projected to grow at the highest CAGR of 5.9% during the forecast period and accounted for more than 40% of molding compounds market share in 2021. This is attributed to proliferating demand for iron & steel from various end-use sectors such as industrial, construction infrastructure, automotive, and others. This has led iron & steel manufacturers to increase their production capacities where molding compounds are widely used for temperature stability purposes. For instance, according to a report published by the India Brands Equity Foundation, finished steel consumption in India is anticipated to increase to 230 metric ton (MT) by 2030-31 from 93.43 metric ton (MT) in 2020-21.

IMPACT OF COVID-19 ON THE GLOBAL MOLDING COMPOUNDS MARKET

- The novel coronavirus is an incomparable global pandemic that has spread to over 180 countries and caused huge losses of lives and the economy around the globe.

- The molding compound market has negative impact due to the wake of the COVID-19 pandemic, owing to the disruptions in the supply chain for various industrial products. The outbreak of COVID-19 resulted in the shutdown of various manufacturing plants for a long period, especially in Europe and Asia-Pacific, owing to which manufacturers have faced shortage in labor units, production losses.

- Furthermore, rising awareness regarding worker security & safety during lockdown, and guidelines by government posed an additional challenge to resume their basic operations in manufacturing unit due to which it has disturbed the production of molding compounds. In the first quarter of the pandemic, there is complete shutdown of building & construction activities, manufacturing industry, and others owing to the strict imposition of lockdown it has hampered the growth of molding compounds market.

- In addition, disruption in production units, closure of manufacturing factories, and cutbacks in service sectors lead to disruption in global logistics and supply chain services. In addition, restrictions imposed, owing to the lockdown have declined growth of construction, automotive, and electronics sectors.

- Moreover, delays in infrastructure investments and complete shutdown of transportation hampered the molding compound market. In addition, as restrictions imposed due to lockdowns are being lifted in the fourth quarter of the pandemic, building & construction, automotive, aerospace, electronics, and manufacturing sectors are expected to recover, owing to the record of production units in both developed and developing economies.

Key Benefits For Stakeholders

- This report provides a quantitative analysis of the market segments, current trends, estimations, and dynamics of the global molding compounds market analysis from 2021 to 2031 to identify the prevailing global molding compounds market opportunities.

- The market research is offered along with information related to key drivers, restraints, and opportunities.

- Porter's five forces analysis highlights the potency of buyers and suppliers to enable stakeholders make profit-oriented business decisions and strengthen their supplier-buyer network.

- In-depth analysis of the global molding compounds market segmentation assists to determine the prevailing market opportunities.

- Major countries in each region are mapped according to their revenue contribution to the global market.

- Market player positioning facilitates benchmarking and provides a clear understanding of the present position of the market players.

- The report includes the analysis of the regional as well as global molding compounds market trends, key players, market segments, application areas, and market growth strategies.

Global Molding Compounds Market Report Highlights

| Aspects | Details |

| By Resin Type |

|

| By Application |

|

| By Region |

|

| Key Market Players | CAPLINQ Corporation, Hitachi Chemical Co., Mar-Bal, Sumitomo Bakelite Co., Ltd., IDI Composites International, BASF SE, Henkel Adhesives, Starfire Systems, SBHPP, Hexion Inc. |

| Other Key Market Players | SPF Composites., Lubrizol, PLEXIGLAS, Evonik, Others |

Analyst Review

According to CXOs of leading companies, the global molding compound market is expected to exhibit high growth potential. Molding compounds are resilient, chemical resistant, and dimensionally stable, owing to which they are widely used in automotive, electrical and electronics, aerospace, industrial, textile, household appliances, and other end-use sectors. This propels growth of the molding compound market.

In addition, polyester resins have a flame retardant property, retentivity of shape, and stability properties, owing to such functionalities polyester molding compounds are used in textile, industrial, and automotive, and other end-use industries. Moreover, it has good thermal stability and prevent heating of electrical and electronics equipment from being overheated.

Furthermore, corrosion resistance property of molding compound enables consumers to use them in both acidic and basic atmospheres. Molding compounds are employed as substitute over metals, owing to its corrosion resistance properties that make customers more linear toward purchasing molding compounds-based products CXOs further added that sustained economic growth and development of the automotive sector led to rise in popularity of molding compounds.

The global molding compounds market was valued at $10.10 billion in 2021, and is projected to reach $ 17.02 billion by 2031, growing at a CAGR of 5.5% from 2022 to 2031.

Growing electronics and automotive sectors are escalating the demand from molding compounds which are the other major growth factors in the molding compounds market.

BASF SE, CAPLINQ Corporation, Eastman Chemical Company, Evonik Industries AG, Henkel AG & Co. KGAA, Mar-Bal, Inc., Owens Corning., PLEXIGLAS, PPG Industries, Inc., SBHPP, SPF Composites, Starfire Systems Inc., Sumitomo Chemical Co., Ltd., The Lubrizol Corporation, and Toray Industries, Inc., are the most established players in the global molding compounds market.

The molding compounds market is segmented on the basis of resin type, application, and region. On the basis of resin type, the market is categorized into polyester, phenolic, epoxy, and others. On the basis of application, it is divided into aerospace, automotive, electrical and electronics, and others. Region-wise, the market is studied across North America, Europe, Asia-Pacific, and LAMEA.

Electrical and electronics industry is projected to increase the demand of molding compounds market.

The novel coronavirus is an incomparable global pandemic that has spread to over 180 countries and caused huge losses of lives and the economy around the globe. The molding compounds market has moderate impact due to the wake of the COVID-19 pandemic, owing to disruptions in the supply chain for various industrial products rise in awareness regarding worker security & safety during lockdown and guidelines by government posed an additional challenge to resume basic operations in manufacturing units, which disturbed production of molding compounds. In the first quarter of the pandemic, there is complete shutdown of building & construction activities, manufacturing industry, and others owing to the strict imposition of lockdown it has hampered the growth of molding compounds market

Increase in population has led to rise in demand for various consumer goods, which, in turn, propel the demand for molding compounds in the packaging sector as they are widely used for manufacturing films & wraps. For instance, according to a report published by the National Investment Promotion and Facilitation Agency, the packaging industry was worth over $917 billion in 2019 and is expected to reach $1.05 trillion by 2024, growing at a CAGR of 2.8%. This acts as one of the key drivers responsible for growth of the molding compound market.

Loading Table Of Content...