Noise, Vibration, And Harshness (NVH) Materials Market Research, 2031

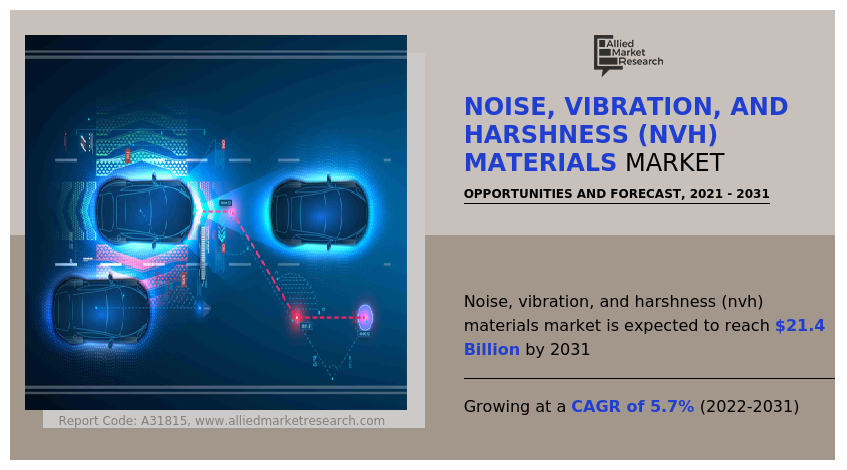

The global noise, vibration, and harshness (NVH) materials market size was valued at $12.5 billion in 2021, and is projected to reach $21.4 billion by 2031, growing at a CAGR of 5.7% from 2022 to 2031.

Report Key Highlighters:

- The noise, vibration and harshness materials market study covers 20 countries. The research includes a segment analysis of each country in terms of both value ($million) and volume (kilotons) for the projected period 2021-2031.

- The study integrated high-quality data, professional opinions and analysis, and critical independent perspectives. The research approach is intended to provide a balanced view of global markets and to assist stakeholders in making educated decisions in order to achieve their most ambitious growth objectives.

- Over 3,700 product literatures, annual reports, industry statements, and other comparable materials from major industry participants were reviewed to gain a better understanding of the market.

- The noise, vibration and harshness materials market is highly fragmented, with several players including 3M, BASF SE, Borgers SE & Co. KGaA, Dow, Eagle Industries, Inc., Henkel Corporation, Huntsman International LLC., NITTO DENKO CORPORATION, Roush Enterprises, and Sumitomo Riko Company Limited. Also tracked key strategies such as acquisitions, product launches, mergers, expansion etc. of the players operating in noise, vibration and harshness materials industry.

The noise, vibration and harshness materials market is composed of automotive material entities that are used to absorb sound and vibration and reduce the impact of noise, vibration, and harshness to provide occupants with a comfortable ride. NVH materials are used to reduce vibration and noise transmitted by various engine accessories such as steering wheels, cooling fans, the floor, and pedals. The demand for NVH material is predicted to expand as automotive manufacturers focus more on noise control and noise reduction in passenger and commercial vehicles to improve fuel efficiency, reduce interior noise, and increase durability.

Increase in demand for NVH materials from automotive industry is driving the noise, vibration and harshness materials market growth.

NVH materials are utilized in commercial vehicles, which are then used to transport goods or passengers. Automotives utilize the NVH material including freight vehicles, corporate vans, minivans, pick-up trucks, and sports utility vehicles, as well as heavy-duty trucks, buses, and coaches. NVH testing and analysis solutions are perfect for optimizing vehicle noise and vibration, such as interior and exterior noise reduction, design, and quality assurance. Acoustic intensity mapping and combustion/mechanical noise separation are two tools that may be used to determine the optimal approach of noise reduction.

The hollow sound-absorbing wheel is a road noise-reducing technology that minimizes tire resonance. Tire resonance is noise in the 200Hz frequency range caused by tires vibration when driving. The vibration of the tires sidewall induced by contact between the tires and the road surface creates an amplitude rise in a resonance inside the tires, resulting in noise. The main objective of noise, vibration, and harshness materials development was to reduce vibration and noise, but it is now important not only to improve practical performance but also to stimulate driver sensitivity and create a natural sound that best fits the vehicle; it is now an era in which customizing and sentimental user experience are important aspects of a vehicle.

NVH materials are used in the automotive industry to eliminate unwanted noise, vibrations oscillations caused by car mechanics, and harshness. NVH materials such as fused rubbers, metal and film laminates, molded foams, and tailored resins are used to control air and structure-borne noise, as well as noise created by automotive interior components. NVH materials have gained popularity in recent years as they absorb noise and keep it from entering the vehicle, reducing discomfort and enhancing ride quality. Noise, vibration, and harshness materials market is utilized in automobiles to alleviate consumer discomfort, which affects vehicle durability. Automobile manufacturers are emphasizing acoustic management and noise reduction in passenger and commercial vehicles to improve fuel efficiency, reduce cabin noise, and increase durability. Thus, the developments in automotive industry boost the growth of the NVH material market expected to drive the market growth during the forecast period.

The active noise control system is a technology that allows manufacturers to achieve better noise control while using less NVH material in their vehicles. This approach uses the vehicle's audio system to reduce low-frequency unwanted noise by emitting sound waves that are the same volume but reversed in phase to the original sound. High-frequency noise requires the use of noise-cancelling material as this approach can only reduce low-frequency noise. Active noise control systems are only concerned with noise cancellation, they cannot compensate for vibrations transmitted throughout the vehicle body. However, as such technology progresses, it may be able to replace NVH control material in the coming years, reducing the need for them. Thus, using active noise control system in vehicles is predicted to hinder the market growth of noise, vibrations and harshness during the forecast period.

In addition, the demand for noise, vibration and harshness materials market is expected to increase in heavy commercial vehicles so as to improve their operational efficiency. Volatility in raw material pricings coupled with the introduction of alternatives such as active noise control systems is expected to hamper the growth of the market. However, governmental regulations on noise reduction coupled with the introduction of recyclable natural NVH materials are expected to boost its market demand by creating potential growth opportunities. Fosshield is a premier fiber technology of Warren Nonwovens Ltd., which offers products without the use of synthetic or chlorinated chemicals.

Rubber, foam, or other materials are designed to isolate and reduce noise, vibration, and harshness in vehicles parts. The system is comprised of the vehicle body, the suspension component, and the tire. According to AZO material, the automobile sector accounts for around 3% of global GDP production, with a bigger contribution in emerging countries like China and India, where the automotive industry accounts for 7% of GDP in November 2022.

The major players operating in the global noise, vibration and harshness materials market include 3M, BASF SE, Borgers SE & Co. KGaA, Dow, Eagle Industries, Inc., Henkel Corporation, Huntsman International LLC., NITTO DENKO CORPORATION, Roush Enterprises, and Sumitomo Riko Company Limited. These players have adopted several strategies to propel the market of NVH material during the forecast period.

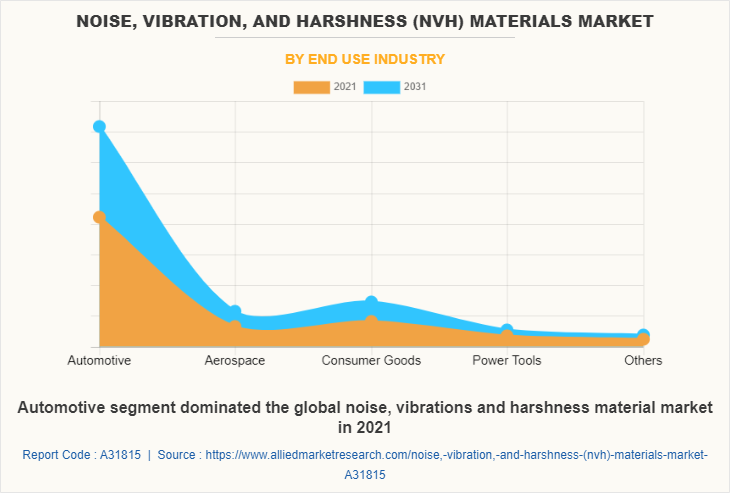

The noise, vibration and harshness materials market is segmented into material, application, end-use industry, and region. On the basis of material, the market is divided into rubber, thermoplastic polymers, engineering resins, and others. On the basis of application, the market is categorized into absorption, insulation, and damping. On the basis of the end-use industry, the market is classified into automotive, aerospace, consumer goods, power tools and others. Region-wise, the noise, vibration, and harshness materials market share is studied across North America, Europe, Asia-Pacific, and LAMEA.

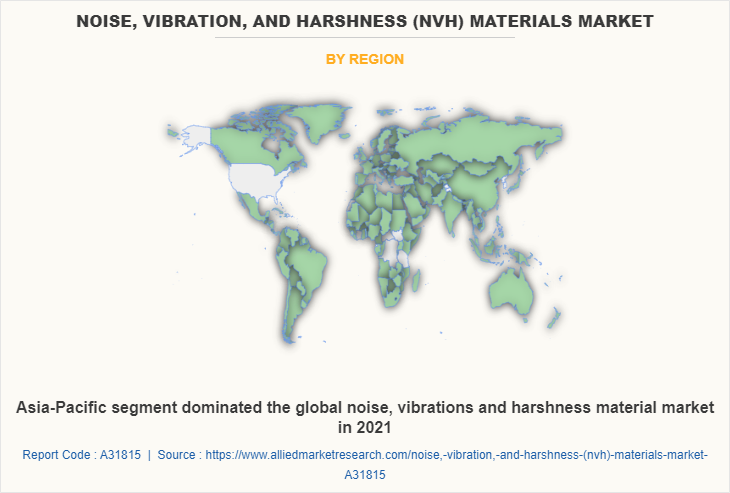

Asia-Pacific is projected to register a robust growth during the forecast period. NVH insulating material contributes to the luxury characteristics of automotive vehicles, such as acoustics and noise reduction when the vehicle is in operation in the Asia-Pacific region. Thermal interface materials, foamed plastics, ceramics, and other materials are also utilized as insulation in the Asia-Pacific region.

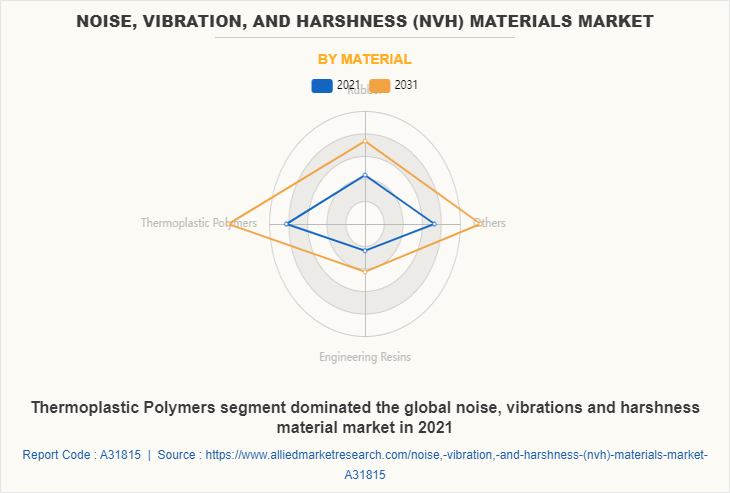

The thermoplastic polymers segment accounted for the largest share of the global noise, vibration and harshness (NVH) materials market in terms of revenue, in 2021. Thermoplastic polymers are used in heat exchangers, sensors, and manifolds in automobile manufacturing parts such as door panels and dashboards. Temperatures of up to 150 degrees Celsius can be sustained by thermoplastic polymers. It is also optically clear and may be molded into complicated shapes. Listed by the National Sanitation Foundation HDPE (High Density Polyethylene) is a versatile and widely used thermoplastic polymer material in automotive noise, vibrations and harshness. It is resistant to chemicals and solvents, making it an ideal material for automotive applications. Thermoplastic polymers are used in heat exchangers, sensors, and manifolds in automobile manufacturing parts such as door panels and dashboards due to their high heat and chemical resistance. Thermoplastic polymers can withstand temperatures of up to 150 degrees Celsius. It may also be molded into intricate shapes and is optically clear

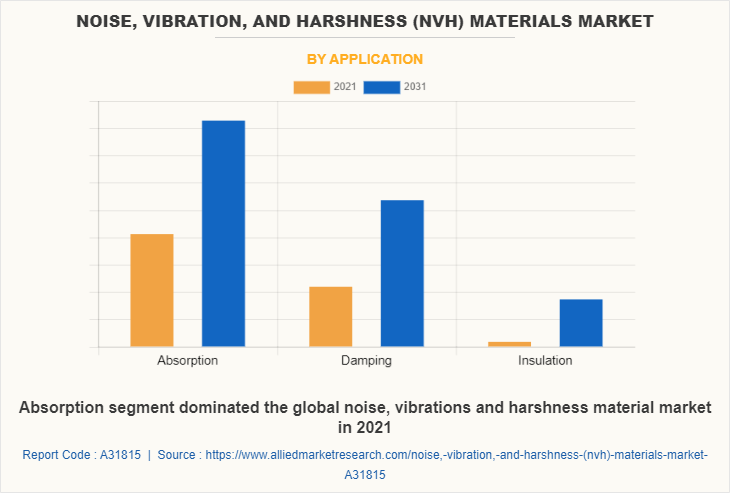

On the basis of application, the absorption segment dominated the global noise, vibration and harshness material market in 2021. NVH absorbing materials encapsulate a thick barrier layer to reduce noise transmission. Car manufacturers employ sound absorption technologies to minimize noise in their vehicles. For high-absorption components, heavy foamed plastics/polyurethane (PUR) hard foam, bitumen, or composite materials are typically utilized. Heavy foamed plastics/polyurethane hard foam, bitumen, or composite materials are widely utilized for high-absorption components. Absorption is only available during vehicle installation for example, between rolled/wound down door panel and window glass.

On the basis of end-use industry, automotive segment dominated the global noise, vibrations and harshness material market in 2021. Noise, vibration and harshness materials market trend was values for a powertrain that are necessary to ensure optimal vehicle noise and vibration behavior in vehicles. Noise, vibration and harshness materials market forecast in automotive to give high-quality assertion of noise within and outside the car, as well as vibration felt by vehicle cabin occupants during a vehicle journey. NVH material in automotive provide high-quality assertion of noise within and outside the car, as well as vibration felt by vehicle cabin occupants during a road transportation. NVH materials are used not just to improve practical performance, but also to increase driving sensitivity and provide a natural in automobiles.

Key Benefits For Stakeholders

- This report provides a quantitative analysis of the market segments, current trends, estimations, and dynamics of the Noise, vibration and harshness materials market analysis from 2021 to 2031 to identify the prevailing noise, vibration, and harshness materials market opportunities.

- The market research is offered along with information related to key drivers, restraints, and opportunities.

- Porter's five forces analysis highlights the potency of buyers and suppliers to enable stakeholders make profit-oriented business decisions and strengthen their supplier-buyer network.

- In-depth analysis of the noise, vibration, and harshness materials market segmentation assists to determine the prevailing market opportunities.

- Major countries in each region are mapped according to their revenue contribution to the global market.

- Market player positioning facilitates benchmarking and provides a clear understanding of the present position of the market players.

- The report includes the analysis of the regional as well as global noise, vibration, and harshness materials market trends, key players, market segments, application areas, and market growth strategies.

Noise, Vibration, and Harshness (NVH) Materials Market Report Highlights

| Aspects | Details |

| Market Size By 2031 | USD 21.4 billion |

| Growth Rate | CAGR of 5.7% |

| Forecast period | 2021 - 2031 |

| Report Pages | 300 |

| By Application |

|

| By Material |

|

| By End Use Industry |

|

| By Region |

|

| Key Market Players | Roush Enterprises, Henkel Corporation, Dow, Sumitomo Riko Company Limited, Huntsman International LLC., 3M, BASF SE, Eagle Industries, Inc., Borgers SE & Co. KGaA, NITTO DENKO CORPORATION |

Analyst Review

According to the opinions of various CXOs of leading companies, the noise, vibrations and harshness material market is anticipated to grow in the future, owing to its extensive use in end-use industry such as automotive, aerospace, consumer goods, power tools and others. Developments in automotive industry boost the NVH material market growth. NVH materials such as melded rubbers, metal and film laminates, molded foams, and engineered resins are used to control air and structure-borne sounds, as well as noise caused by car interior components.

However, usage of active noise control system in vehicles is expected to restrain industry expansion whereas, rise in use of NVH material in sports, leisure, and gym equipment is expected to provide sufficient development prospects for the noise, vibrations and harshness material market in the future years.

Moreover, Asia-Pacific region is projected to register a robust growth during the forecast period. In Asia-Pacific, NVH is generally used for insulation and absorption in hybrid electric vehicles (HEVs), plug-in hybrid electric vehicles (PHEVs), fuel cell electric vehicles (FCEVs), and battery electric vehicles (BEVs), where there is a demand for rubber, thermoplastic polymers, and engineering resins.

The global noise, vibration and harshness materials market was valued at $12.5 billion in 2021, and is projected to reach $21.4 billion by 2031, registering a CAGR of 5.7% from 2022 to 2031.

The major players operating in the global noise, vibrations and harshness material market include 3M, BASF SE, Borgers SE & Co. KGaA, Dow, Eagle Industries, Inc., Henkel Corporation, Huntsman International LLC., NITTO DENKO CORPORATION, Roush Enterprises, and Sumitomo Riko Company Limited.

Asia-Pacific is the largest regional market for noise, vibration, and harshness materials market.

Automotive industry is the leading application of noise, vibration, and harshness materials market.

Developments in the automotive industry and also increase in demand for noise, vibration, harshness materials in electrical vehicles is boosting the market growth.

Loading Table Of Content...