North America Industry 4.0 Market Insights:

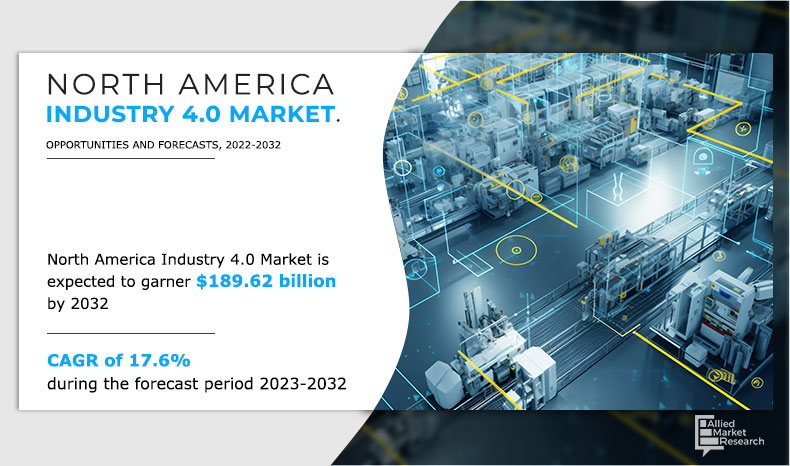

The North America industry 4.0 market was valued at USD 38.59 billion in 2022 and is projected to reach USD 189.62 billion by 2032, growing at a CAGR of 17.6% from 2023 to 2032

Industry 4.0, which refers to the fourth industrial revolution, is the cyber-physical transformation of manufacturing. The name is inspired by Germany's Industrial 4.0, a government initiative to promote connected manufacturing and a digital convergence among industry, businesses, and other processes. Moreover, companies benefit from personalized offerings, reduced costs, improved efficiencies, and increased production as a result of the fourth industrial revolution (i4.0). IIoT, augmented & virtual reality, 3D printing, and blockchain are just a few examples of the digital technologies that disrupt every step of the value chain, including product design, supply chains, manufacturing techniques, and customer experiences.

In addition, strategic government initiatives to digitize production processes across various sectors support global manufacturing industry giants such as the U.S. In manufacturing, industry 4.0 has widespread repercussions. It is used to leverage operational efficiency, refine demand forecasting, break down data silos, engage in predictive maintenance, and offer workers boosts to safety and virtual training.

The report focuses on growth prospects, restraints, and trends of the North America industry 4.0 market outlook. The study provides Porter’s five forces analysis to understand the impact of various factors, such as bargaining power of suppliers, competitive intensity of competitors, threat of new entrants, threat of substitutes, and bargaining power of buyers, on the North America industry 4.0 market forecast.

Segment Review:

The North America industry 4.0 market is segmented on the basis of technology and end user. On the basis of technology, it is segregated into industry automation, 3D printing, digital twin, artificial intelligence (AI) & machine learning (ML), blockchain, extended reality (XR), industrial internet of things (IIoT), and others. On the basis of end user, it is divided into manufacturing, automotive, oil & gas, energy & utilities, food & beverages, aerospace & defense, and others.

Depending on the technology type, the industry automation segment dominated the North America industry 4.0 market share in 2022 and is expected to continue this dominance during the forecast period, owing to essential elements of Industry 4.0 to detect, measure, analyze, and process various transitions in industrial production facilities, such as changes in positions, length, height, exterior, and dislocations. However, the blockchain segment is expected to witness the highest growth in the upcoming years, owing to enhanced security, privacy, and data openness. Moreover, blockchain technology is widely recognized to benefit the supply chain and manufacturing environments.

The report analyzes the profiles of key players operating in the North America industry 4.0 market such as Cognex Corporation, Schneider Electric SE, Emerson Electric Co., Rockwell Automation Inc., Cisco Systems Inc., ABB Ltd., Siemens AG, Honeywell International Inc., General Electric Company, International Business Machines Corporation. These players have adopted various business strategies such as product launch, partnerships, and business development to increase their market penetration and strengthen their position in the North America industry 4.0 market.

By Technology Type

Industry automation segment accounted for the highest market share in 2022

Market Landscape and Trends:

The advent of Industry 4.0 results in enhanced productivity possibilities for both small and medium-sized enterprises (SMEs). SMEs can profit from valuable information from their data by utilizing cloud technology, Big Data, and analytic solutions. This implies that they can shift from reactive to predictive maintenance, identify the areas for improvements, minimize waste, and intensify yield. Furthermore, such technologies have a significant impact on quality management, which can lead to saving costs.

In addition, due to the early adoption of trending technologies, such as IoT, big data, DevOps, and mobility, manufacturers in North America are keen to integrate IoT technologies in their processes. Moreover, the growing number of SMEs and increasing digitization in manufacturing by large enterprises, such as IBM and General Electric, have also aided the growth of the North American IoT in the manufacturing sector. SMEs are flexible in incorporating new technologies into their existing systems, whereas large manufacturers have heavy budgets for digitization. Therefore, these are the major market trends that provide lucrative growth opportunities to the North America industry 4.0 market size.

The COVID epidemic has accelerated the expansion of industry 4.0 in the North American region, advancing companies from various industries to a higher level of Internet of Things (IoT) technology and workflow. During the pandemic, industry 4.0 was being transformed by a number of cutting-edge technologies, including cloud computing, artificial intelligence (AI), 5G networks, and big data. In addition, the surge in use of 3D printing technology for medical devices and the increase in adoption of AI & IoT in wearable and medical devices created a number of growth prospects for the market. Furthermore, due to the pandemic restrictions, the growing attraction of 5G in the field of cloud robotics significantly boosted the North America industry 4.0 market size.

Top Impacting Factors:

Rise in Adoption of Industrial Robots

Robots have evolved over the past few decades from being prohibitively expensive devices with limited functionality to being affordable devices capable of carrying out a variety of duties. Particularly industrial robots are extensively used by people everywhere. Industrial robots are being used more frequently in manufacturing centers, which is driving rapid advancements, development, and evolution, according to the most recent trends in the robotics industry. Moreover, rapid technological advancements in robotics have led to an increase in acceptance of robotics engineering and technology in the manufacturing sector's production processes. Industrial robots are programmable, multipurpose manipulators that operate autonomously.

Furthermore, few common industrial robot applications include welding, heavy lifting, ironing, assembling, picking & positioning, palletizing, product inspection, and testing. All of these tasks require a lot of human endurance, speed, and accuracy. The International Federation of Robotics (IFR) estimates that in 2021, a total of 486,800 units were transported globally. Industrial robots carry out repetitive tasks and substitute for human labor where necessary. They can also work in dangerous and risky environments where humans cannot. Robotics technology is thus expected to be a major development in the North America industry 4.0 market growth.

Rise in Deployment of Additive Manufacturing

Additive manufacturing, or 3D printing, is one of today's most creative tools. In recent years, 3D printing has been widely used to meet the increase in ventilator valve demand in hospitals across the globe. Moreover, the manufacturing industry's current trends are about to alter as a result of 3D printing technology.

Governments are launching programs and funding organizations that conduct research and create technology to further explore the possibilities offered by 3D printing technology and to promote its growth. National programs are being implemented in the U.S., and Canada to support university-level 3D printing study, which is advancing technology and spawning start-ups. Future industrialists and governments from across the globe are expected to be drawn to 3D printing as new applications for the technology arise, which is projected to provide lucrative growth opportunities for the North America industry 4.0 market.

By End User

Manufacturing segment accounted for the highest market share in 2022.

Rise in Use of Artificial Intelligence

Artificial intelligence (AI) contributes to the recent developments in Industry 4.0. Industries focus on improving product consistency, productivity, and reducing operating costs, and they want to achieve this with the collaborative partnership between robotics and people. In smart industries, hyperconnected manufacturing processes depend on different machines that interact using AI automation systems by capturing and interpreting all data types. Smart platforms of automation can play a decisive role in transforming modern production.

AI provides appropriate information to take decision-making and alert people of possible malfunctions. Industries use AI to process data transmitted from the Internet of things (IoT) devices and connected machines based on their desire to integrate them into their equipment. It provides companies with the ability to track their entire end-to-end activities and processes fully. Therefore, these factors drives the market growth of North America industry 4.0.

Increase in Adoption of 5G in the Field of Cloud Automation

The increase in use of robots in manufacturing facilities across the globe has led to a steady increase in demand for cloud robotics. The goal of cloud robotics is to integrate the system intelligence with the industrial robots already in place.

A high-performance network such as 5G, which provides higher bandwidth and lower latency than Wi-Fi, is now required due to the widespread use of cloud robotics in the manufacturing sector. Moreover, real-time video and large dataset activities are supported by 5G. It has gained popularity in robotics as it makes it simple to integrate factory-deployed robots with the cloud network. Furthermore, increase in penetration of 5G services in various other sectors provides lucrative growth opportunities.

Key Benefits for Stakeholders:

- This report provides a quantitative analysis of the market segments, current trends, estimations, and dynamics of the North America industry 4.0 market analysis from 2023 to 2032 to identify the prevailing North America industry 4.0 market opportunity.

- The market research is offered along with information related to key drivers, restraints, and opportunities.

- Porter's five forces analysis highlights the potency of buyers and suppliers to enable stakeholders make profit-oriented business decisions and strengthen their supplier-buyer network.

- In-depth analysis of the North America industry 4.0 market segmentation assists to determine the prevailing market opportunities.

- Major countries in each region are mapped according to their revenue contribution to the market.

- Market player positioning facilitates benchmarking and provides a clear understanding of the present position of the market players.

- The report includes the analysis of the regional as well as North America industry 4.0 market trends, key players, market segments, application areas, and market growth strategies.

North America Industry 4.0 Market Report Highlights

| Aspects | Details |

| By Technology Type |

|

| By End User |

|

| Key Market Players | General Electric Company, Cisco Systems Inc., Honeywell International Inc., Rockwell Automation Inc., Schneider Electric SE, ABB Ltd., Siemens AG, International Business Machines Corporation, Cognex Corporation, Emerson Electric Co. |

Analyst Review

According to CXOs of leading market players, enterprises across North America need to understand the implications and opportunities presented by Industry 4.0 to make informed decisions and stay ahead of the curve. The North American Industry 4.0 market signifies a transformative shift in the manufacturing sector. It has the potential to transform conventional manufacturing processes, empowering enterprises to achieve higher levels of efficiency, productivity, and innovation.

Many organizations now understand that adopting Industry 4.0 technologies is no longer a choice, however, a necessity to remain competitive in today's rapidly evolving business landscape. One of the key benefits of the North American Industry 4.0 market is the ability to create "smart factories" through the incorporation of advanced technologies such as IoT, AI, robotics, and data analytics. This allows real-time data collection, analysis, and decision-making, leading to enhanced operational efficiency along with improved quality control. Enterprises understand that by leveraging these technologies, they can enhance their production processes, simplify supply chain management, and satisfy the increasing demand for customized and personalized products.

Furthermore, enterprises recognize that Industry 4.0 presents opportunities for cost reduction and revenue expansion. By implementing automation and robotics, organizations can cut-down labor costs, minimize errors, and achieve higher production volumes. In addition, the utilization of data analytics enables predictive maintenance, allowing organizations to proactively address equipment malfunctions before they become expensive downtime. Moreover, Industry 4.0 creates new revenue streams through the development of smart products and services that cater to evolving customer demands and preferences.

For instance, in September 2022, Hitachi, Ltd. acquired industry 4.0 systems Integrator Flexware Innovation, Inc. ("Flexware Innovation") which has been a leading manufacturing systems integrator (SI) since 1996. Flexware Innovation was a strategic acquisition for Hitachi due to its focus on the TOTAL SEAMLESS SOLUTION*1 that links "shop floor" and "top floor" with data and digital technology.

With this acquisition of Flexware Innovation, Hitachi strengthened and enhanced its business in the domain of MES (Manufacturing Execution Systems), SCADA (Supervisory Control and Data Acquisition), Software Development, Business Intelligence (BI), and ERP (Enterprise Resource Planning) implementation capabilities in North America, and accelerate the digitalization with JR Automation, which engages in the robotic SI & automation.

Loading Table Of Content...