North America Railway Automated Inspection Equipment Market Statistics 2027 -

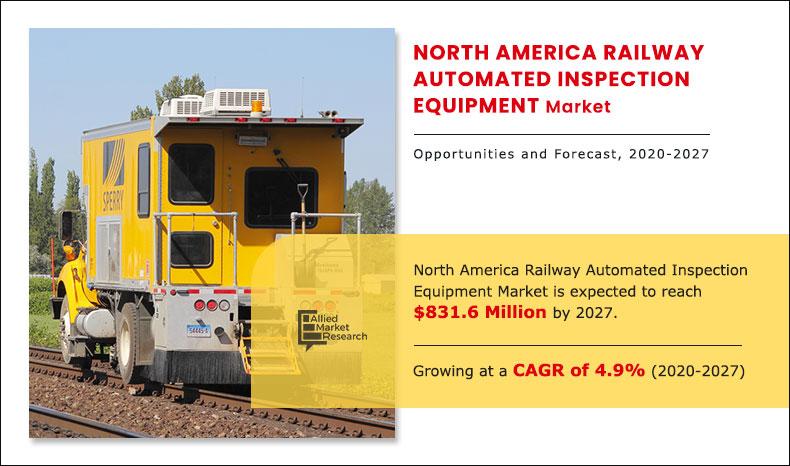

The North America railway automated inspection equipment market was valued at $643.6 million in 2019, and is projected to reach $831.6 million by 2027, registering a CAGR of 4.9%.

Railway automated inspection equipment is a specialized rail track inspection equipment operated by the trained operator to collect and analyze the railroad inspection data points. This equipment is majorly installed line-fitted or retro-fitted on the special track inspection vehicles to perform rail inspection activities.

This equipment has integration of high-end technology to gather and process the collected track inspection data with the cost as well as time effectiveness. In North America, the private railways of the U.S., Mexico, and Canada are vertically integrated companies, competing with other private companies across large areas of land and large markets. These railway operators open the contracts for maintenance activities on periodic basis for effective rail transportation activities.

Factors, such as increase in demand for passenger and freight capacity and rise in number of railway projects across North America, are expected to drive the growth of the railway automated inspection equipment market. In addition, increase in concern for railroad inspection and maintenance activities is anticipated to act as a key driver of the market. However, factors, such as growing penetration of autonomous inspection technology and requirement for skilled workforce to operate the inspection equipment, restrain the market growth. On the contrary, entering into strategic partnership with rail operators to gain competitive advantage and technological innovation at railway transportation front are projected to offer lucrative growth opportunity for the market players.

The North America railway automated inspection equipment market is segmented on the basis of inspection system, offering, inspection vehicle, and country. Inspection system is divided into track geometry measurement system, rail profile measurement system, third-rail measurement system, and others. Depending on offering, the market is categorized into solution or equipment and services. On the basis of inspection vehicle, it is classified into self-propelled vehicle, towed coaches, hi-rail vehicles. Country-wise, the market is analyzed across the U.S., Canada, and Mexico.

The key players operating in the North America railway automated inspection equipment market are Ensco, Inc., Geismar Corporation, Harsco Corporation, Holland LP, Loram Maintenance of Way, Inc., MER MEC S.p.A., Nordco, Inc., Pavemetrics, Plasser & Theurer, Sperry Rail Inc., and others.

Increase in demand for passenger and freight capacity

The railway industry has witnessed significant growth in passenger ridership as compared to other public transit, owing to its fare frequency and overall commute time. According to Organization for Economic Cooperation and Development (OECD), passenger transport by rail for million passenger-kilometers has witnessed steady growth over the past decade. According to the similar source, the U.S. registered 23,490 million passenger–kilometers in 1998, which attained 32,483 million passenger-kilometers in 2019. Mexico registered 460 million passenger–kilometers in 1998, which attained 1,571 million passenger-kilometers in 2019. Moreover, Canada registered 1,469 million passenger-kilometers in 1998, which reached 1,685 million passenger-kilometers in 2018.

Moreover, in 2019, the U.S. witnessed around 60% increase in rail ridership since 1997, and is expected to continue the same trend in the near future. Rail transit in the U.S. is holding around 48% of the total public transit. Railway has witnessed a significant rise in ridership, and is expected to continue in the coming years. Therefore, increase in ridership is expected to create demand for cost-effective and operational efficient rail solutions. For seamless operations of the rail transportation system, railways are needed to be inspected at priority for ensuring operational efficiency. Increasing passenger density and growing fright capacity are expected to create the requirement for optimum operation of the rail transportation system, which, in turn, supports the growth of the railway automated inspection equipment market in the coming years.

By Inspection System

Rail Profile Measurement System Segment is projected as the most lucrative segment

Increase in concern for railroad inspection and maintenance activities

Railway inspection and maintenance equipment is used in the railway industry for track inspection, maintenance, repair, and ballast cleaning. This equipment is used in railroad inspection applications, owing to features such as ensuring safety, saving time, maximizing the speed of travel, and improving the performance of railway track. Inspection activities are always in-line to the future footsteps for maintenance and repair activities for ensuring optimum performance level of the railroad tracks to avoid accidents and railway asset losses. Changing mobility outlook across

North American countries and trade logistics requirement imposing the demand for highly efficient rail road transportation create the requirement for railroad transportation and maintenance activities across the region. In addition, governments of several countries in North America are introducing revised track inspection standards to improve the operational efficiency of railway activities. For instance, in August, 2020, the U.S. Department of Transportation’s (DoT’s) Federal Railroad Administration (FRA) submitted to the federal register a final rule stating the use of ultrasonic inspection technology allowing for railroads, which improved with GPS technology to perform continuous rail testing activities.

These updated regulations make easier activities for frequent railroad testing and identify the rail line issues before the railroad degrade to improve safety. This utilization of continuous rail testing involves rail inspection vehicles to internally examine rail without stopping. Increasing usage of ultrasonic inspection technology is expected to support the growth of the railway automated inspection equipment market in the coming years.

By Offering

Services segment is projected as the most lucrative segments

Technological innovation at railway transportation front

Companies dealing in railway automated inspection equipment are adopting high-end technologies, such as GPS, several data gathering and processing software, and others, in their products. These railway automated inspection equipment are technologically advanced as compared to old railway inspection machinery products. The changing inspection frequency of railroad and requirement for minimizing the inspection time duration along with error-free inspection activities create the requirement for high-end technology enabled equipment.

To cater to the changing requirement of the end users and attaining the rail road inspection and maintenance standards set by the authorities, market participants are continuously upgrading the product offerings. For Instance, in September, 2019, Holland LP launched a new gage inspector at railway interchange in 2019. It offers real-time gauge measurement and usable under any conventional hi-rail vehicle. Further, this product offers hang-on geometry systems for fulfilling track testing needs.

By Inspection Vehicle

Hi-rail Vehicles segment is projected as the most lucrative segments

COVID-19 impact analysis

The major impact is experienced by public mobility as people are suggested to stay at home and prefer work from home wherever possible. From March 2020, public transport in majority of the big cities in North America has been completely or partially shut. Restriction on public mobility has been lifted partially since June 2020; however, major cities in North America are experiencing 70% to 90% reduction in public transportation ridership. This massive downfall impacted the public transportation provider’s revenue generation while some transport applications need support from the federal government to regularize their services. In addition, the second wave of COVID-19 hit in February 2021 to majority of the countries across the globe. This second wave has a savior impact on the overall economic activities as this strain spreads rapidly than the first wave of COVID-19, thereby creating a health crisis. This second wave limits the demand from consumers due to lower consumer confidence. Moreover, rail passenger has decreased significantly from March 2020 due to commute restrictions across the North America region. However, only essential goods movement was taking place through rail transport. This downfall in overall rail transportation activities was attributed to the significant impact of COVID-19, which affected the railway automated inspection equipment market in 2020.

By Country

U.S. would exhibit the highest CAGR of 5.2% during 2020-2027.

Key Benefits For Stakeholders

- This study presents the analytical depiction of the North America railway automated inspection equipment market analysis along with the current trends and future estimations to depict imminent investment pockets.

- The North America railway automated inspection equipment market opportunity is determined by understanding profitable trends to gain a stronger foothold.

- The report presents information related to key drivers, restraints, and opportunities of the market with a detailed impact analysis.

- The current North America railway automated inspection equipment market is quantitatively analyzed from 2019 to 2027 to benchmark the financial competency.

- Porter’s five forces analysis illustrates the potency of the buyers and suppliers in the industry.

Key Market Segments

By Inspection System

- Track Geometry Measurement System

- Rail Profile Measurement System

- Third-rail Measurement System

- Others

By Offering

- Solution or Equipment

- Services

By Inspection Vehicle

- Self-propelled Vehicle

- Towed Coaches

- Hi-rail Vehicles

By Country

- U.S.

- Canada

- Mexico

KEY PLAYERS

- Ensco, Inc.

- Geismar Corporation

- Harsco Corporation

- Holland LP

- Loram Maintenance of Way, Inc.

- MER MEC S.p.A.

- Nordco, Inc.

- Pavemetrics

- Plasser & Theurer

- Sperry Rail Inc.

North America Railway Automated Inspection Equipment Market Report Highlights

| Aspects | Details |

| By INSPECTION SYSTEM |

|

| By OFFERING |

|

| By INSPECTION VEHICLE |

|

| By COUNTRY |

|

| Key Market Players | HOLLAND LP, MER MEC S.P.A., GEISMAR CORPORATION, NORDCO, INC., SPERRY RAIL INC., LORAM MAINTENANCE OF WAY, INC., HARSCO CORPORATION, PAVEMETRICS, ENSCO, INC., PLASSER & THEURER |

Analyst Review

North America railway automated inspection equipment market is expected to grow at a remarkable rate in the near future, owing to growing number of rail road expansion projects in North America, adoption of high-end technologies in rail inspection activities, and changing rail transportation outlook in North America. The U.S. is a leader in the North America market, owing to its rail maintenance standards and rail lines network across the country. Moreover, the U.S. maintain its dominance in the market during the forecast period along with significant growth rate due to upcoming rail line expansion project in the country along with stringent regulations for railroad quality and safety.

The North America railway automated inspection equipment market is a fairly consolidated market in which countable market participants are operating in the region. Numerous developments have been carried out by top companies, such as Ensco, Inc., Geismar Corporation, Holland LP, Loram Maintenance of Way, Inc., MER MEC S.p.A., and others, which have supplemented the growth of the North America railway automated inspection equipment market.

The impacts of COVID-19 significantly affected the North America railway automated inspection equipment market in 2020. Furthermore, the market witnessed negative growth or significant downfall in 2020. However, in 2021, rail operators are planning to do modernization and railway maintenance of the existing railway infrastructure, which is expected to spur the demand for railway automated inspection equipment and witness recovery in the market.

Loading Table Of Content...