Pet Bottle Blow Molding Machine Market Research, 2032

The global pet bottle blow molding machine market size was valued at $0.9 billion in 2023, and is projected to reach $1.2 billion by 2032, growing at a CAGR of 3.2% from 2024 to 2032.

Market Introduction and Definition

Blow molding machines for PET bottles are specialized devices designed to transform PET preforms into finished bottles through a precise process of heating, stretching, and blowing. These machines are essential across various industries, ensuring efficient and high-quality bottle production. The operation begins with the preform loader, which feeds PET preforms into the machine. The preforms are then uniformly heated in the heating unit to reach the necessary pliable state. In the blow molding unit, the heated preform is placed into a mold, where it undergoes mechanical axial stretching followed by high-pressure air blowing, which expands the preform against the mold walls to form the bottle. Once formed, the bottles are cooled to solidify their shape and then ejected from the machine.

Key Takeaways

- The PET bottle blow molding machine market studies more than 23 countries. The analysis includes a country-by-country breakdown analysis in terms of value ($million) available from 2023 to 2032.

- The research combined high-quality data, professional opinion, and research, with significant independent opinion. The research methodology aims to provide a balanced view of the global Pet Bottle Blow Molding Machine Market, and help stakeholders make educated decisions to achieve ambitious growth objectives.

- The research reviewed more than 3, 700 product catalogs, annual reports, industry descriptions, and other comparable resources from leading industry players to gain a better understanding of the market.

- The key players in the PET bottle blow molding machine market are Sidel Group, Krones AG, Nissei ASB Machine Co., Ltd., SIPA S.p.A., Aoki Technical Laboratory, Inc., KHS GmbH, SMI S.p.A., SACMI Group, Kautex Maschinenbau GmbH, and Jomar Corporation. Major strategies such as product launch, partnerships, and expansion of players operating in the market are tracked and monitored.

Industry 4.0 Trends:

Industry 4.0, often referred to as the Fourth Industrial Revolution, has rapidly transformed various industries, including blow molding. It emphasizes enhanced interconnectivity and smart automation. In the context of blow molding, Industry 4.0 leverages the capabilities of machines, sensors, devices, and operators to connect and communicate via the internet, leading to increased productivity and reduced costs. This revolution in manufacturing technology is particularly beneficial for the blow molding industry, as it allows for predictive maintenance strategies, real-time information on equipment performance, and automatic ordering of raw materials on the basis of usage history, all contributing to an optimized process and a higher return on investment.

- Machinery Development: In September 2021, CHUMPOWER Industrial Co., Ltd. and the Industrial Technology Research Institute joined hands to improve the production capacity of linear blow molding machines of the CPSB-LSS8 type PET bottle blowing machine through mechanical design optimization. Industry 4.0 technologies elements such as multi-point temperature detector have been incorporated in the machine to collect the temperature of each preform after heating. Multi-point temperature uses a model similar to neural network for automatic compensation.

- Plant Development: In the early 2019, FlexBlow, a family-owned company founded in 1994 specializing in PET stretch blow molding technology, added a new 3, 500-square-meter manufacturing facility to its 10, 000-square-meter site in Kretinga, Lithuania. The company is expanding its capacity and improving its stretch blow mold (SBM) machine capabilities. This new facility is expected to include various industry 4.0 technology elements.

Key Market Dynamics

The PET bottle blow molding machines market expansion is driven by several factors, including the rise in demand for PET bottles in various industries such as beverages, pharmaceuticals, and personal care. The beverage industry holds a significant share, with approximately 65% of the market demand, owing to a rise in consumption of bottled water, carbonated drinks, and juices globally. In addition, technological advancements in blow molding machines, leading to improved efficiency and lower operational costs, are fueling Pet Bottle Blow Molding Machine Market growth. Moreover, the rise in emphasis on sustainability and recyclability pushes manufacturers to invest in eco-friendly packaging solutions, further boosting the demand for PET bottle blow molding machines. However, one restraint faced by the market is the high initial investment required for acquiring and setting up these machines, which deter small and medium-sized enterprises from entering the market. Nonetheless, this challenge presents an opportunity for manufacturers to offer leasing or financing options to attract a wider customer base and tap into previously untapped markets, thereby fostering market expansion.

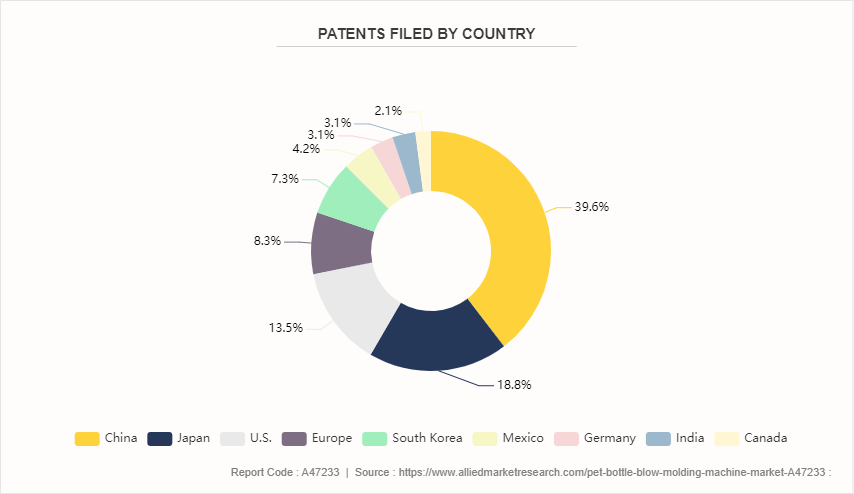

Patent Analysis of PET Bottle Blow Molding Machine Market

Patent analysis serves as a valuable tool for Pet Bottle Blow Molding Machine Market Forecast and strategic decision-making, helping companies identify opportunities for collaboration, licensing, or acquisition. By tracking patent filings, companies are able to anticipate future market trends, prioritize research & development efforts, and gain a competitive advantage in the rapidly evolving PET bottle blow molding machines market.

Market Segmentation

The PET bottle blow molding machine market is segmented into machine type, technology, end user, and region. By machine type, it is categorized into injection stretch blow molding machines (ISBM) , extrusion blow molding machines (EBM) , stretch blow molding machines (SBM) , injection blow molding machines (IBM) , and others. By technology, it is classified into Single Stage, Two Stage, And Hybrid. On the basis of end user, the market is divided into food & beverages, pharmaceuticals, and others. Region wise, the market is analyzed across North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa.

Regional Market Outlook

The Pet Bottle Blow Molding Machine Industry exhibits diverse regional dynamics, with North America, Europe, Asia Pacific, Latin America, and the Middle East & Africa each presenting unique opportunities and challenges. In North America, particularly the U.S., stringent regulations promoting sustainable packaging solutions and a robust demand across industries such as beverages, pharmaceuticals, and personal care drivePet Bottle Blow Molding Machine Market Growth. Europe, a mature market, emphasizes advanced technologies and quality standards, with Germany, Italy, and the UK leading in Pet Bottle Blow Molding Machine Market Share. Asia Pacific emerges as the fastest-growing region, fueled by rapid industrialization and urbanization, especially in China and India, where the food and beverage industry is booming. Latin America, including Brazil, Mexico, and Argentina, sees substantial growth potential driven by changing consumer lifestyles and government initiatives promoting sustainable packaging. Meanwhile, the Middle East & Africa region, though slower in pace, shows increasing adoption of PET bottles in various applications, particularly in countries like Saudi Arabia, South Africa, and the United Arab Emirates. Overall, these regional dynamics reflect a complex interplay of factors such as industrial development, regulatory environment, and consumer preferences, shaping the trajectory of the Pet Bottle Blow Molding Machine Market Overview on a global scale.

Government Guidelines:

- China- The Chinese government has implemented regulations aimed at promoting environmental sustainability and reducing plastic waste. For instance, by 2025, China aims to achieve a recycling rate of 85% for PET bottles. Moreover, guidelines prioritize the adoption of eco-friendly packaging solutions, including PET bottles, to minimize environmental impact. In 2020, China introduced a ban on single-use plastics in major cities, further driving demand for recyclable alternatives.

- India- The Indian government focuses on promoting domestic manufacturing capabilities and reducing dependence on imported machinery. As part of the "Make in India" initiative, the government aims to increase domestic production of PET bottle blow molding machines by 20% by 2025. Incentives such as tax incentives and subsidies are offered to encourage investment in indigenous production of PET bottle blow molding machines. Companies investing in research and development of indigenous technologies can benefit from tax exemptions of up to 100%.

Competitive Landscape

The major players operating in the PET bottle blow molding machine market include Sidel Group, Krones AG, Nissei ASB Machine Co., Ltd., SIPA S.p.A., Aoki Technical Laboratory, Inc., KHS GmbH, SMI S.p.A., SACMI Group, Kautex Maschinenbau GmbH, and Jomar Corporation.

Other players in the PET bottle blow molding machine market include SMF Maschinenfabrik GmbH, Tech-Long Packaging Machinery Co., Ltd., Chumpower Machinery Corp., Parker Plastic Machinery Co., Ltd., and Amsler Equipment Inc.

Key Sources Referred

- Plastics Industry Association (PLASTICS) - Represents the entire plastics supply chain and provides industry data.

- Association of Plastic Recyclers (APR) - Focuses on the recycling of plastics, including packaging.

- American Chemistry Council (ACC) - Provides information on the plastics industry, including packaging materials.

- European Plastics Converters (EuPC) - Represents the European plastics converting industry, including packaging.

- The Packaging Federation - Represents the UK packaging manufacturing industry and provides data on packaging trends.

- Flexible Packaging Association (FPA) - Represents the flexible packaging industry and provides relevant market data.

- The British Plastics Federation (BPF) - Represents the UK plastics industry, including packaging, and offers industry insights.

- Sustainable Packaging Coalition (SPC) - Promotes sustainable packaging solutions and provides data on packaging sustainability.)

Key Benefits For Stakeholders

- This report provides a quantitative analysis of the Pet Bottle Blow Molding Machine Market segments, current trends, estimations, and dynamics of the pet bottle blow molding machine market analysis from 2024 to 2032 to identify the prevailing pet bottle blow molding machine market opportunities.

- The market research is offered along with information related to key drivers, restraints, and opportunities.

- Porter's five forces analysis highlights the potency of buyers and suppliers to enable stakeholders make profit-oriented business decisions and strengthen their supplier-buyer network.

- In-depth analysis of the pet bottle blow molding machine market segmentation assists to determine the prevailing market opportunities.

- Major countries in each region are mapped according to their revenue contribution to the global Pet Bottle Blow Molding Machine Market.

- Market player positioning facilitates benchmarking and provides a clear understanding of the present position of the market players.

- The report includes the analysis of the regional as well as global pet bottle blow molding machine market trends, key players, market segments, application areas, and market growth strategies.

Pet Bottle Blow Molding Machine Market Report Highlights

| Aspects | Details |

| Market Size By 2032 | USD 1.2 Billion |

| Growth Rate | CAGR of 3.1% |

| Forecast period | 2024 - 2032 |

| Report Pages | 203 |

| By Machine Type |

|

| By Technology |

|

| By End User |

|

| By Region |

|

| Key Market Players | Nissei ASB Machine Co., Ltd., Aoki Technical Laboratory, Inc., SIPA S.p.A., SMI S.p.A., Krones AG, Kautex Maschinenbau GmbH., Jomar Corporation, KHS GmbH., Sidel Group., SACMI Group |

Analyst Review

The PET bottle blow molding machines market is experiencing significant expansion, driven by multiple factors. Key among these is the increasing demand for PET bottles across various industries, particularly in the beverages, pharmaceuticals, and personal care sectors. The beverage industry, in particular, holds a dominant share of approximately 65% of the market demand. This substantial share is attributed to the growing consumption of bottled water, carbonated drinks, and juices globally.

Technological advancements in blow molding machines are another critical factor fueling market growth. Innovations in this field have led to machines with improved efficiency, reduced operational costs, and enhanced production capabilities. These advancements not only make the production process more cost-effective but also increase the attractiveness of PET bottle blow molding machines for manufacturers.

In addition to efficiency improvements, there is a growing emphasis on sustainability and recyclability in packaging. Consumers and regulatory bodies are increasingly advocating for eco-friendly packaging solutions. In response, manufacturers are investing in the development and production of PET bottles that are easier to recycle and have a smaller environmental footprint. This trend is driving further demand for PET bottle blow molding machines, as companies seek to align with sustainable practices and meet the rising consumer and regulatory expectations.

Despite these positive trends, the market does face some challenges. One significant restraint is the high initial investment required for acquiring and setting up blow molding machines. This substantial capital outlay can deter small and medium-sized enterprises (SMEs) from entering the market, as they may lack the necessary financial resources.

However, this challenge also presents an opportunity for manufacturers. By offering leasing or financing options, machine producers can attract a broader customer base, including SMEs that might otherwise be unable to afford the high upfront costs. These financial solutions can make it more feasible for smaller businesses to invest in blow molding machines, thereby tapping into previously untapped markets and fostering further market expansion.

Moreover, the growing trend of customization in packaging solutions is pushing manufacturers to develop versatile and flexible blow molding machines that can cater to varying customer needs. This adaptability is crucial in a market where consumer preferences and industry requirements are constantly evolving. By offering machines that can produce a wide range of bottle shapes and sizes, manufacturers can cater to a diverse clientele, further driving market growth.

In summary, the PET bottle blow molding machines market is poised for substantial growth, driven by rising demand in key industries, technological advancements, and a strong emphasis on sustainability. While high initial investment costs pose a challenge, innovative financing options and a focus on versatile, eco-friendly solutions are set to propel the market forward.

Inclusion of industry 4.0 technology is an upcoming trends of Pet Bottle Blow Molding Machine Market in the globe.

Food & beverage industry is the leading end user of Pet Bottle Blow Molding Machine Market.

Asia-Pacific is the largest regional market for Pet Bottle Blow Molding Machine.

The PET bottle blow molding machine market was valued at $0.9 billion in 2023.

The key players in the PET bottle blow molding machine market are Sidel Group, Krones AG, Nissei ASB Machine Co., Ltd., SIPA S.p.A., Aoki Technical Laboratory, Inc., KHS GmbH, SMI S.p.A., SACMI Group, Kautex Maschinenbau GmbH, and Jomar Corporation.

Loading Table Of Content...