Table Of Contents

- Harnessing the History of Ground Support Equipment

- Significance of Ground Support Equipment

- Peering into the Perks of Ground Support Equipment

- Are the Key Technological Advancements in Ground Support Equipment Driving Progress?

- Electrification

- Automation and Robotics

- Connectivity and Data Analytics

- Can Sustainability and Stride go Hand-in hand?

- Challenges and Future Directions

- Summing up

Lalit Janardhan Katare

Akshata Tiwarkhede

Ground Support Equipment: The Backbone of Efficient Aviation Operations

Harnessing the History of Ground Support Equipment

Ground support equipment serves as the foundation of the aviation industry. The equipment underwent a notable transformation from modest beginnings to modern advancements, revolutionizing the way aircraft receives ground support. In 1990s, the aviation industry was in the nascent stage of development, when ground support equipment was nearly nonexistent. For operational needs and minimal maintenance, basic tools and manual labor served the purpose. However, Wright brothers—the pioneers of aviation technology—realized the importance of ground support. Wilbur Wright became the world's first ramp agent who provided support to the Wright Flyer during its first historic flight in 1902.

Aircraft played a pivotal role during World War I, when ground support equipment gained high traction, as it served as a crucial component in aerial operations. Hucks Starter—an auxiliary power unit, which majorly was applicable in the agricultural sector—found its way into aviation, thus emphasizing the impact of agricultural equipment on ground support technology. It was majorly required to draw extra power for the startup of piston engine.

As air travel gained high traction in 1992, FMC Corporation introduced baggage loaders, cargo handling systems, and deicers, which marked a major milestone in the aviation industry. In 1997 and beyond, the advent of aerial lifts, specialized tow tractors, and electric charging stations shaped the growth trajectory of the aviation industry. With increasing focus on sustainability, the introduction of zero-emission ground support equipment and hybrid-electric models played a significant role in enhancing the operational efficiency along with mitigating the environmental impact.

Presently, the integration of cutting-edge technologies such as data analytics, AI, and telematics into ground support equipment have elevated their operational efficiency and performance. With sustainability being the major focus in the present age, key players are developing eco-friendly equipment to achieve net-zero emissions and mitigate the environmental impact.

Developments are being carried out by the key companies & associations to offer superior quality equipment. For instance, in May 2024, the International Air Transport Association (IATA) launched a program reinforcing the industry’s aim of increasing the use of enhanced ground support equipment (Enhanced GSE). Presented at IATA’s Ground Handling Conference (IGHC), the IATA Enhanced GSE Recognition Program aims to accelerate the introduction of Enhanced GSE technologies into daily operations, by recognizing those ground handlers who are leading this modernization of their vehicle fleets. The first ground handlers to obtain this recognition at various stations are HACTL and Menzies Aviation.

Significance of Ground Support Equipment

Ground support equipment is vital for efficient operation of airports and airlines, notably impacting various aspects of airport and airline performance. The equipment ensures quick turnaround times by facilitating efficient baggage handling, aircraft servicing, and passenger movement, which are essential for maintaining tight flight schedules and minimizing delays. By reducing the time aircraft spend on the ground, airlines can maximize aircraft utilization, leading to more flights and increased revenue opportunities. Safety is another critical factor enhanced by the use of ground support equipment. Aviation demands the highest safety standards, and ground support equipment plays a pivotal role in meeting these standards. Properly maintained and operated equipment help to prevent accidents on the tarmac, protecting ground personnel and ensuring that aircraft are properly serviced and in optimal condition for flight. This includes everything from safe baggage handling to precise refueling, which collectively contribute to overall flight safety.

Cost savings are also a significant benefit of efficient equipment. By reducing ground time, airlines can lower operational costs, as aircraft spend less time idle and more time in the air generating revenue. Efficient fuel management facilitated by equipment such as ground power units and fueling trucks can result in substantial fuel savings, further reducing operational expenses. The passenger experience is directly influenced by the effectiveness of the equipment. Prompt and efficient baggage handling ensures that luggage arrives on time, while quick and thorough aircraft servicing minimizes delays and improves on-time departure rates. Moreover, comfortable and efficient passenger transport between terminals and aircraft contributes to a smoother and more pleasant travel experience. These factors are crucial for customer satisfaction and the overall reputation of airlines, as a positive travel experience encourages customer loyalty and repeat business.

Thus, ground support equipment is integral for seamless operations of airports and airlines, enhancing operational efficiency, safety, cost savings, and passenger experience. Its role in minimizing delays, ensuring safety, reducing costs, and improving customer satisfaction underscores its critical importance in the aviation industry.

Peering into the Perks of Ground Support Equipment

The benefits of various types of ground support equipment are multifaceted, enhancing the efficiency, safety, and environmental sustainability of airport operations. Aircraft tugs and tractors streamline the movement of aircraft on the ground, reducing the need for engine taxiing, which conserves fuel and minimizes emissions. Passenger stairs and boarding bridges enhance passenger convenience and safety, facilitating smooth and efficient boarding and deboarding processes. This is particularly crucial during tight turnaround times, helping airlines maintain schedules and improve passenger satisfaction.

Ground power units and air start units provide essential support to aircraft while they are parked, supplying electrical power and pneumatic pressure. This support allows aircraft systems to function without the need for running auxiliary power units, leading to fuel savings and reduced noise pollution. Similarly, refueling trucks and hydrant systems ensure quick and safe delivery of fuel, which is critical to maintain flight schedules and operational efficiency.

Baggage handling equipment, such as conveyor belts, baggage carts, and loaders, improve the speed and accuracy of luggage processing, reducing the risk of lost or delayed baggage. This efficiency is mirrored in cargo handling equipment, which ensures that freight is loaded and unloaded swiftly and safely, a vital component for airports handling significant cargo volumes.

De-icing equipment is essential in colder climates, ensuring aircraft can safely operate in adverse weather conditions. This equipment not only improves safety but also minimizes delays and cancellations due to snow. Maintenance support equipment, including stands, lifts, and tool kits, enable ground crews to perform necessary inspections and repairs quickly and effectively, ensuring aircraft are airworthy and reducing the likelihood of in-flight issues.

Environmental sustainability is another critical benefit of modern ground support equipment. The adoption of electric and hybrid equipment reduces greenhouse gas emissions and operational costs. Innovations such as solar-powered ground power units and energy-efficient tugs demonstrate the aviation industry's commitment to environmental responsibility, contributing to a greener and more sustainable future.

Overall, the diverse range of ground support equipment significantly enhances the operational efficiency, safety, and environmental sustainability of airport operations, reflecting the industry's ongoing evolution and adaptation to new challenges and technological advancements.

Are the Key Technological Advancements in Ground Support Equipment Driving Progress?

The aviation industry is continually evolving, and so is the technology behind ground support equipment. Innovations in this field aim to enhance efficiency, reduce environmental impact, and improve safety.

Electrification

One of the most significant trends in ground support equipment is the shift toward electrification. Electric equipment reduces emissions, noise, and operational costs. Airports and airlines are increasingly adopting electric baggage tugs, belt loaders, and ground power units. The reduced reliance on fossil fuels aligns with global sustainability goals and regulatory requirements.

Automation and Robotics

The advent of automation is profoundly transforming the operations within the aviation industry. Revolutionary advancements in technology have led to the development of autonomous vehicles and robots designed to handle various tasks traditionally performed by human operators. These innovations encompass critical functions such as baggage transport, aircraft towing, and cargo loading, offering a multitude of benefits, including increased efficiency, reduced labor costs, and minimized human error. One significant application of automation in ground support operations is the deployment of autonomous baggage handling systems for airports. These systems utilize automated guided vehicles equipped with sophisticated navigation and routing algorithms to transport baggage from check-in counters to the aircraft. By optimizing routing and handling processes, autonomous baggage handling systems streamline operations while significantly reducing the risk of mishandling and loss. The precise coordination and efficient movement of baggage not only enhance operational efficiency but also contribute to a smoother passenger experience by ensuring that luggage reaches its destination promptly and intact.

Another area of automation involves the utilization of autonomous tow tractors. These self-driving vehicles are capable of moving aircraft without the need for human intervention, leveraging advanced sensor technology and navigation systems to ensure precise and safe movement on the tarmac. By eliminating the reliance on manual towing operations, autonomous tow tractors reduce the risk of accidents and improve operational safety while also increasing efficiency by optimizing aircraft positioning and turnaround times. This innovative approach to aircraft towing represents a significant step forward in ground support automation, offering a reliable and cost-effective solution for airport ground handling operations. These innovative solutions offer numerous advantages, including increased efficiency, reduced labor costs, and enhanced safety, thereby paving the way for more streamlined and effective ground handling processes in airports around the world.

Connectivity and Data Analytics

The integration of connectivity and data analytics into ground support operations represents a transformative shift in how equipment is monitored and managed in the aviation industry. Central to this evolution are telematics systems, which provide real-time data on the location, status, and performance of equipment. This wealth of information enables operators to monitor equipment in real-time, facilitating proactive maintenance, efficient asset management, and strategic operational planning. With insights into factors such as utilization rates, fuel consumption, and engine performance, operators can optimize equipment deployment, identify opportunities for improvement, and make informed decisions to enhance overall efficiency and productivity.

Furthermore, the implementation of predictive maintenance systems is revolutionizing maintenance practices required for ground support equipment. By leveraging data analytics to analyze historical performance data and identify patterns, predictive maintenance systems can anticipate potential issues before they escalate into critical failures. This proactive approach to maintenance reduces downtime, extends the service life of equipment, and lowers maintenance costs by minimizing the need for reactive repairs and unplanned maintenance activities. By addressing maintenance needs in a timely manner and prioritizing resources effectively, predictive maintenance systems ensure that equipment remain in optimal condition, maximizing operational uptime and reliability.

The integration of connectivity and data analytics into ground support operations is driving significant improvements in equipment monitoring and management. Telematics systems provide real-time visibility into equipment performance, while predictive maintenance systems enable proactive maintenance practices. Together, these technologies empower operators to optimize equipment operations, enhance reliability, and improve overall efficiency in ground handling operations within the aviation industry.

Can Sustainability and Stride go Hand-in hand?

Technological advancements in ground support equipment include the development of electric and hybrid vehicles, which has led to reducing in emissions and operational costs. For instance, electric tugs, such as the Mototok Spacer 8600, reduce the fuel usage to a much larger extent. Solar-powered ground power units, such as those offered by ITW GSE, provide sustainable power solutions for parked aircraft. Advanced de-icing trucks, like the Vestergaard Elephant Beta, use precise spraying technology to minimize fluid waste. In addition, automated baggage handling systems improve efficiency and accuracy, reducing turnaround times and enhancing overall airport operations. These innovations reflect the industry's shift toward greater efficiency and environmental sustainability.

Furthermore, significant advancements in the design and materials used in ground support equipment have led to notable improvements in efficiency, durability, and operator comfort. One of the key trends driving this evolution is the adoption of lightweight and durable materials, particularly composite materials, in the construction of equipment. By incorporating composite materials, manufacturers are able to create both lighter and more robust equipment compared to traditional materials like steel or aluminum. This reduction in weight not only enhances the agility and maneuverability of vehicles such as tow tractors and passenger buses but also contributes to fuel savings by reducing energy consumption during operation.

The increased durability of composite materials leads to reduced maintenance costs, further enhancing cost-effectiveness and operational efficiency. Moreover, innovations in design have played a crucial role in enhancing the functionality and versatility of modern equipment. One notable aspect of this evolution is the focus on ergonomic design principles, which prioritize the comfort and well-being of equipment operators. Modern equipment are meticulously engineered with ergonomic features such as adjustable seating, intuitive control interfaces, and optimized cabin layouts, all aimed at minimizing physical strain and fatigue during prolonged use. By prioritizing ergonomics, manufacturers are able to improve operator comfort, reduce the risk of injuries, and enhance overall productivity and safety in ground support operations.

This emphasis on ergonomic design not only benefits operators but also contributes to the efficient and effective handling of ground support tasks, ultimately optimizing the performance of ground support equipment and the entire airport operation. Overall, the integration of lightweight materials and ergonomic design principles represents a significant advancement in the evolution of ground support equipment, enabling airports and airlines to achieve greater efficiency, reliability, and safety in ground handling operations.

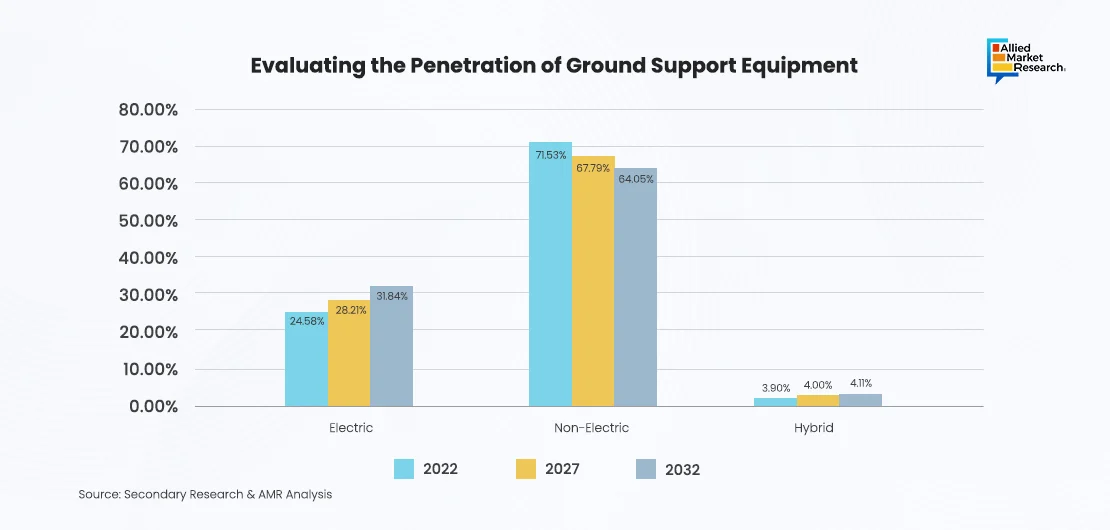

Above image represents the penetration of ground support equipment based on different propulsion types. Among them, non-electric ground support equipment witnessed the highest penetration in 2022 of approximately 71.5%; however, they are projected to encounter a decline in the usage by 2032 by approximately 64% due to the electrification in the machinery across the globe. Electric-powered equipment encountered around 24.5% penetration in 2022, exhibiting an upward growth in the usage by 31.8% by 2032. This increased inclination toward electrified equipment is due to the demand for advanced equipment to be present at airports to reduce human efforts.

Challenges and Future Directions

The shift toward electric and automated ground support equipment represents a significant transformation in airport operations, but it comes with its own set of challenges and considerations, particularly in the areas of infrastructure, standardization, workforce training, and environmental impact. The transition to electric and automated equipment requires substantial investment in infrastructure. Airports must invest in installing charging stations, upgrading power grids, and developing facilities to accommodate autonomous vehicle operations. However, securing funding for these upgrades can be challenging, especially for smaller airports with limited resources. Overcoming these financial hurdles is essential to facilitate the widespread adoption of advanced ground support equipment.

Standardization is another critical aspect that requires attention. Harmonizing ground support equipment standards across different airports and airlines is crucial for interoperability and efficiency. The aviation industry must establish common standards for electric charging interfaces, communication protocols, and safety regulations to ensure seamless integration and operation of advanced systems. Moreover, the introduction of new technologies in ground support equipment necessitates a skilled workforce capable of operating and maintaining advanced equipment. Comprehensive training programs and certification courses are essential to equip ground personnel with the necessary skills and knowledge to effectively utilize these technologies. Investing in workforce training is vital to maximizing the potential benefits of electric and automated equipment while minimizing operational disruptions. Furthermore, while electrification of ground support equipment helps reduce emissions and mitigate environmental impact, it is crucial to consider the broader ecological implications. For example, the production and disposal of batteries used in electric equipment have environmental consequences. To address this, the industry must adopt sustainable practices throughout the service life of equipment, including eco-friendly manufacturing processes, battery recycling initiatives, and emissions reduction strategies. By prioritizing environmental sustainability, the aviation industry can minimize its ecological footprint and contribute to a more sustainable future.

The transition to electric and automated ground support equipment presents both opportunities and challenges for airports and airlines. By addressing infrastructure needs, promoting standardization, investing in workforce training, and adopting sustainable practices, the industry can overcome these challenges and unlock the full potential of advanced equipment while minimizing environmental impact.

The above image represents the utilization of ground support equipment in 2022, highlighting an industry valuation of $7,972.2 million, which is projected to reach $14,242 million by 2032. This increased valuation is majorly attributed to the inclination toward electrified equipment at airports across the globe.

Summing up

Ground support equipment is the backbone of aviation operations, ensuring that aircraft are serviced, passengers are handled, and cargo is transported efficiently and safely. The advancements in ground support equipment, such as electrification, automation, and data analytics, are transforming the industry, making operations more efficient and environmentally friendly. However, challenges such as infrastructure investment, standardization, workforce training, and environmental impact need to be addressed to fully realize the benefits of these innovations. As the aviation industry continues to evolve, the capabilities of equipment will evolve simultaneously, thereby driving the sector toward higher efficiency, safety, and sustainability.

For further insights, get in touch with AMR analysts!