Table Of Contents

Yerukola Eswara Prasad

Koyel Ghosh

Hydrogen: The Fuel of the Future

Hydrogen is a gaseous element found abundantly in nature. Hydrogen is combustible in nature and needs to be handled cautiously. It is an essential product in the chemical industry, which can be used as a raw material as well as a product. It serves various application sectors such as chemical, automotive, oil & gas and so on. The hydrogen industry is currently in development stage, as the full potential of hydrogen is yet to be realized. According to AMR, the global hydrogen market is expected to register a CAGR of more than 6% between 2022 and 2032.

Hydrogen offers several advantages, making it valuable across various industries. Its high energy density per unit mass allows for the storage of large amounts of energy and helps stabilize the grid by managing fluctuations in supply and demand. In the energy sector, it is favored for its flexibility and responsiveness. Fuel cells powered by hydrogen produce only water as a byproduct, reducing air pollution and greenhouse gas emissions. These cells are more efficient than internal combustion engines, converting chemical energy directly into electrical energy, and providing greater convenience compared to battery electric vehicles (BEVs) by offering longer driving ranges, making them ideal for the automotive industry.

Additionally, hydrogen benefits as a feedstock in numerous chemical processes, including the production of ammonia for fertilizers and methanol. It can also replace carbon-intensive feedstocks and reducing agents in processes like steel production, leading to significant reductions in CO? emissions. This versatility and potential for clean energy make it a crucial component in the transition to a sustainable and low-carbon energy future.

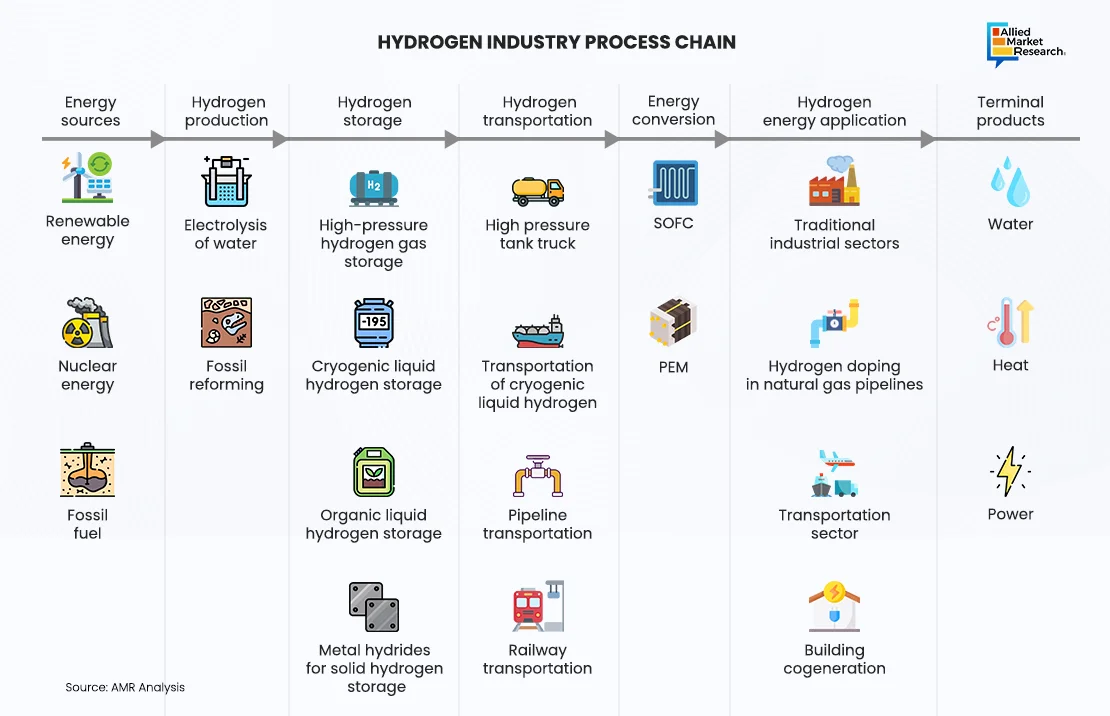

The figure shows that hydrogen, from generation to final downstream products, serves various end-use industries. Hydrogen is one of the clear sources of fuel, which can be used for power generation as well as in the automotive industry.

Hydrogen utilized in various end-use industries are basically categorized into three types namely blue hydrogen, grey hydrogen, and green hydrogen. Blue hydrogen is produced from natural gas and supported by carbon capture and storage. The CO2 generated during the manufacturing process is captured and stored permanently underground. The result is low-carbon hydrogen that produces no CO2. Grey hydrogen is produced from fossil fuels without implementing carbon capture and storage (CCS) processes. In contrast, green hydrogen is generated using renewable energy or low-carbon power sources. Unlike grey hydrogen, which is primarily produced through steam reforming of natural gas and dominates the hydrogen market, green hydrogen results in significantly lower carbon emissions.

The Rise of Green Hydrogen: A Sustainable Solution for Energy and Transportation

Increasing Demand for Green Hydrogen

Green hydrogen refers to hydrogen gas production through a process called electrolysis using renewable energy sources, such as wind, solar, or hydroelectric power. The electrolysis process separates hydrogen molecules from water molecules, creating a clean and sustainable form of hydrogen fuel without emitting greenhouse gases or pollutants. Governments are setting ambitious climate targets, and industries are under pressure to decarbonize. Green hydrogen has emerged as a promising, zero-emission energy carrier capable of replacing fossil fuels in various sectors, including transportation, heavy industry, and power generation. Its production from renewable energy sources aligns seamlessly with the objectives of combating climate change and reducing greenhouse gas emissions.

For instance, The Inflation Reduction Act (IRA) of U.S. provides up to a $3/kg hydrogen production tax credit, resulting in 50%-75% reduction in the expected cost of hydrogen production. This tax credit is essential for significantly expanding production, given the current high costs compared to competing fuels. The U.S. Treasury Department and IRS issued proposed regulations at the end of 2023 that specify the credit eligibility parameters, granting the maximum credit to hydrogen production with very little or no carbon emission. In India, regulations and recommendations have been established requiring the Centre, State, and Local Government Bodies to obtain a total of approximately 73 approvals. These approvals cover various areas such as fire safety, land allocations, pollution control, and general legal requirements, among others.

Technological advancements in electrolyzers are crucial for driving the growing demand for green hydrogen. These technological strides focus to enhance efficiency, scalability, and cost-effectiveness, driving the widespread adoption of electrolysis for its production. Improvements in electrolyzer designs aim to increase efficiency by reducing energy consumption and optimize the conversion of electrical power into hydrogen gas. Innovations in materials, such as the development of advanced catalysts and membranes, are enhancing electrolyzer performance by enabling faster reactions and increasing durability. Additionally, scaling up manufacturing processes and adopting modular designs for electrolyzers are making large-scale production more feasible, leading to economies of scale and lower costs. These technological advancements are expected to significantly boost the growth of green hydrogen and the hydrogen industry in the coming years.

Development of Hydrogen Fuel Cell

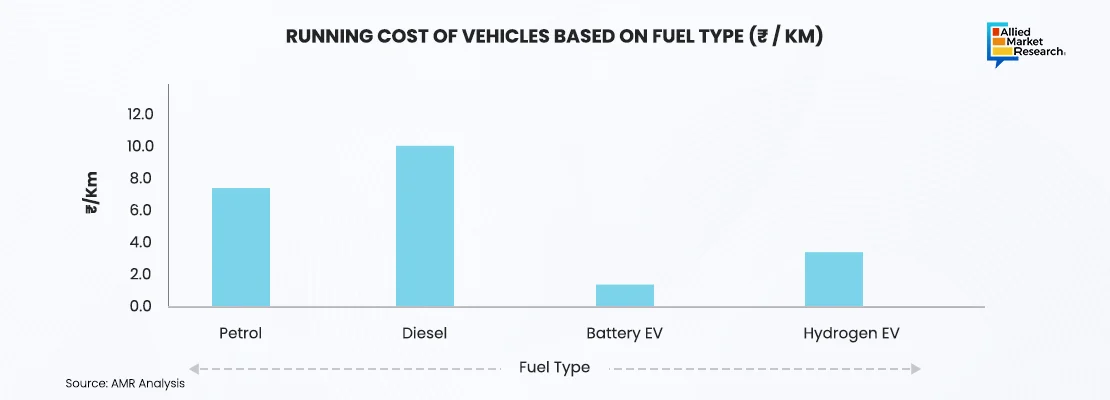

Green hydrogen is utilized in the automotive industry through fuel cells, offering a cost-effective and environmentally friendly alternative to petroleum products like petrol and diesel. Unlike internal combustion engines, which emit various pollutants, these fuel cells produce only water as a by product.

Here it can be seen that in India, the cost of operating a diesel internal combustion engine vehicle is the highest, averaging over INR 9.9 per kilometer. In contrast, battery electric vehicles have the lowest running cost, at approximately INR 1.5 per kilometer. On the contrary, hydrogen based electric vehicles have a running cost of INR 3.3 per KM, which is almost half of petrol-based vehicles.

Battery electric vehicles (BEV), although having a low running cost, require a considerable charging time period. Under normal circumstances, a thorough 100% charge for a BEV requires 8 hours, providing a driving range of around 300 KM (185 miles). In contrast, hydrogen electric vehicles (HEVs) can be refueled in a manner similar to internal combustion engine vehicles and offer a driving range of 800 KM (500 miles). Infrastructure for both BEVs and HEVs is currently being developed in India, many European countries, the U.S., Canada, and beyond. Advancements are being made in fuel cell technology to increase efficiency and make it commercially viable for the passenger car segment. For instance, in March 2024, Intelligent Energy (U.K.) launched IE-DRIVE, a new fuel cell system that is smaller and more powerful than any other solution in the passenger car segment. This innovation will provide automotive manufacturers with a powerful, turnkey, and commercially viable fuel cell solution.

Researchers aim to enhance the design, production, and commercialization of fuel cell technologies, recognizing their potential to significantly impact the future of transportation and infrastructure. These fuel cells are anticipated to offer an alternative to battery-powered solutions for heavy-duty and long-distance truck transportation, particularly in scenarios where reliable electrical charging infrastructure is lacking or the battery size required would be impractical.

Fuel cells play a significant role in decarbonizing the transportation sector, especially for heavy-duty vehicles, buses, trains, and even maritime and aviation applications. Their fast-refueling times and long range make them ideal for these applications. The development of pipelines and distribution networks intends to facilitate the widespread use of hydrogen across various sectors. Additionally, efforts are being made to produce it from renewable sources like wind, solar, and hydropower, which could reduce the environmental impact of its production. According to a study by AMR, the green hydrogen market is expected to register a CAGR of more than 50% between 2023 and 2032. As a result, the hydrogen economy could create new job opportunities in manufacturing, infrastructure development, maintenance, and research, driven by the increasing demand for clean energy solutions.

Looking ahead

Overall, the future of hydrogen fuel cells is promising, with potential to revolutionize multiple sectors and contribute significantly to a sustainable and low-carbon energy future. Hydrogen fuel is key to the future of energy, providing a versatile and eco-friendly solution to some of our biggest environmental problems. It produces zero emissions when used in fuel cells, making it a great alternative to fossil fuels, especially in areas where it's hard to switch to electricity. Recent improvements in how we produce, store, and use hydrogen are making it more practical and affordable.

Allied Market Research provides comprehensive insights into the rapidly expanding hydrogen sector. Our meticulously crafted reports cover the latest technological advancements, market trends, and relevant government initiatives. It equips businesses with the essential knowledge to effectively integrate green hydrogen into their offerings. Staying informed on these key areas enables companies to make strategic decisions and capitalize on emerging market opportunities. For expert guidance on materials, energy, and power related to green hydrogen, reach out to our team today!