Table Of Contents

Yerukola Eswara Prasad

Koyel Ghosh

Incorporation Analysis: Carbon Nanotubes Usage in Different End-use Industries

Carbon nanotubes (CNTs) are cylindrical nanostructures composed entirely of carbon atoms arranged in a unique hexagonal pattern. Discovered in 1991 by Sumio Iijima, carbon nanotubes have since garnered immense attention from researchers across various fields due to their potential applications in electronics, materials science, nanotechnology, and beyond. There are two primary types of carbon nanotubes, such as single-walled carbon nanotubes and multi-walled carbon nanotubes. SWCNTs are carbon nanotubes made up of a single layer of carbon atoms tightly rolled into a seamless cylindrical shape, resembling a tube formed by wrapping a sheet of graphene. MWCNTs, on the other hand, consist of multiple concentric layers of graphene cylinders nested within one another.

Properties of Carbon Nanotubes

Exceptional Mechanical Strength: Carbon nanotubes showcase high tensile strength, surpassing those of most materials known to humanity. Their high aspect ratio and strong covalent bonds between carbon atoms contribute to their exceptional mechanical properties.

High Electrical Conductivity: CNTs exhibit excellent electrical conductivity, making them suitable for various electronic applications. SWCNTs are particularly known for their metallic or semiconducting behavior, depending on their chirality.

Lightweight: Despite their exceptional strength, CNTs are lightweight, which is beneficial for applications where weight reduction is critical, such as in aerospace and automotive industries.

Flexibility and Resilience: They are flexible and can undergo significant deformation without breaking. They can also recover their shape after deformation, making them resilient materials for various structural applications.

Chemical Stability: They are chemically stable under normal environmental conditions, exhibiting resistance to oxidation, corrosion, and chemical degradation.

Optical Properties: Moreover, these cylindrical nanostructures display unique optical properties, including high absorbance across a wide range of wavelengths and low reflectance. These properties make them attractive for applications in photonics, optoelectronics, and sensors.

Biocompatibility: In certain forms and with appropriate surface functionalization, carbon nanotubes have also shown potential biocompatibility, making them suitable for biomedical applications such as drug delivery, imaging, and tissue engineering.

CNTs offer various properties for use in base materials such as polymers and reinforcements, thus making them useful in different end-use industries, such as aerospace & defense, automotive, pharmaceutical, sporting goods, energy & power and so on. Many CNT manufacturers are focusing on increasing the penetration level in end-use industries. In order to achieve this, they are paying special attention toward price reduction and bulk production.

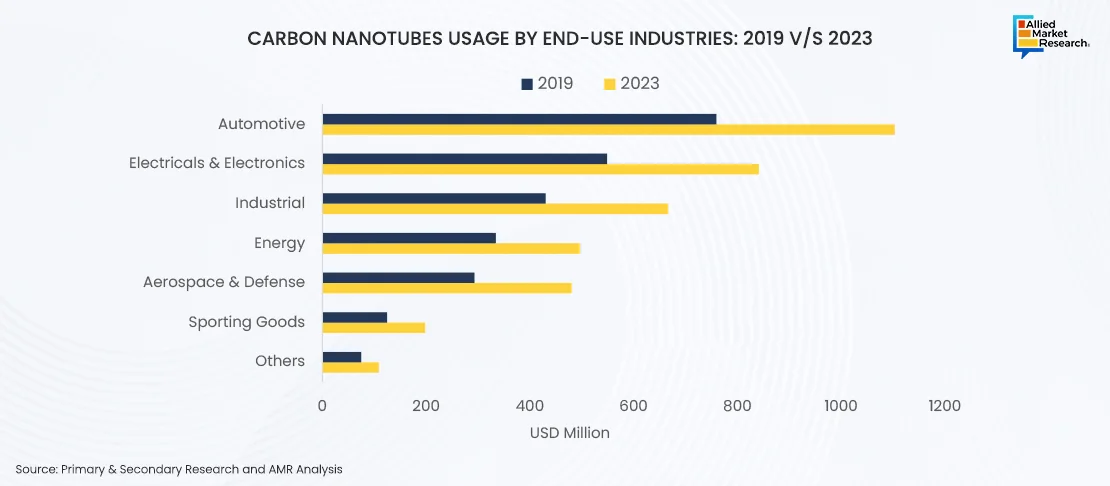

The above figure showcases the usage of CNTs in different end-use industries between 2019 and 2023. Automotive followed by electrical & electronic end-use industry are the major consumers of CNTs between this period and are expected to continue the trend in the coming years also. These end-use industries are also showcasing more than 20% between 2019 and 2023.

To observe the incorporation level of these structures in different end-use industries, we need to observe and analyze certain parameters that will provide insights into the demand perspective.

High Demand End-use Industries

Automotive

CNT is one of the most preferred products to be used in the automotive industry as compared to superalloys, composites, and other products. They are used in interior components as well as exterior components, such as battery components, dashboards, gas pump holders, fenders, mirror housings, door handles and many more. Automotive OEMs are focusing on decreasing the weight of automobiles to increase their fuel efficiency, thus meeting the emission norms formulated by various Governments. For instance, in the model year 2026, passenger cars and light trucks are required by the Corporate Average Fuel Economy (CAFÉ) standards to achieve an average of 49 miles per gallon (mpg).

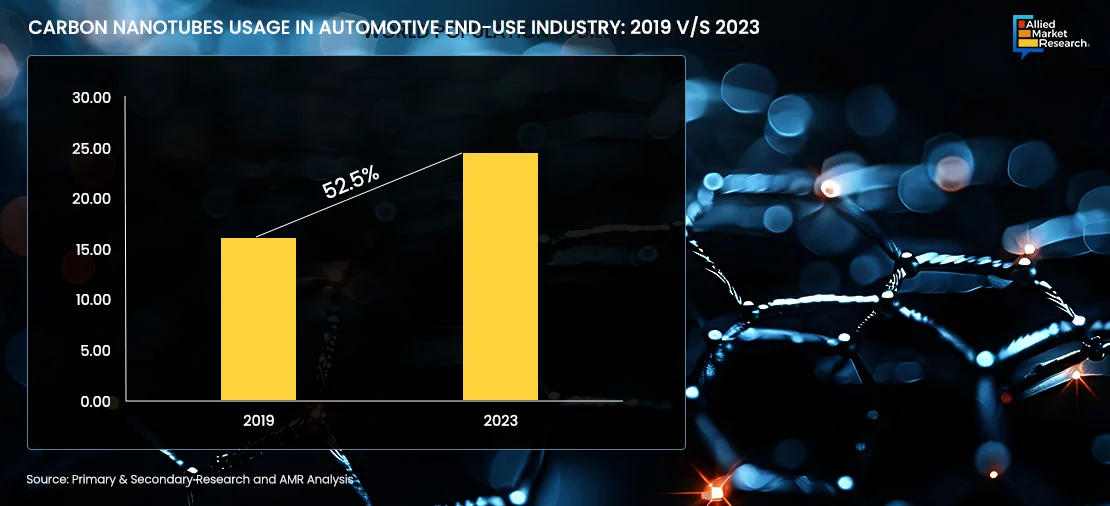

As per the above figure, the average CNT usage in automobiles was around 16.1 grams per vehicle in 2019, which increased to 24.4 grams per vehicle in 2023, an increase of 52.5% during this period. This increase in usage is predominantly attributed to the fact that the prices of multi-walled carbon nanotubes (MWCNTs) witnessed a substantial price reduction, while single-walled carbon nanotubes (SWCNTs) witnessed a marginalized price reduction. Thus, with price reduction, the demand for CNTs is bound to increase considerably. With automotive OEM hubs in countries like China, India, Japan, Brazil and so on, the demand for CNTs from these emerging economies is expected to increase significantly in the coming years. According to the study by AMR, the carbon nanotubes market in automotive end-use industry is expected to register a CAGR of more than 16% between 2021 and 2030.

CNT is among the strongest materials with important implications throughout the automotive industry. They enhance the strength of vehicle bodies and decrease their weight, resulting in improved fuel efficiency. These nanotubes are incorporated into metals for the purpose of creating lighter engines, can substitute carbon black in tires to enhance their durability, and offer the additional capability of in situ pressure sensing. Adding a small proportion of CNTs to a polymer matrix can confer conductivity, effectively addressing static electricity concerns that could otherwise pose a fire hazard in vehicles. Moreover, they are utilized in braking components and tire reinforcements. In fuel systems, plastics have replaced metals, which creates a risk of explosion in fuel systems due to electrostatic discharge (ESD). Therefore, ESD materials utilizing CNTs find applications in fuel pumps, fuel filter housings, connectors, reservoirs, line clips, and electronic housings. For instance, in 2019, car maker BMW showcased its new car BMW X6 coated with Vantablack. Vantablack is a coating of high-aspect ratio carbon nanotubes that virtually reflects no light.

Aerospace

The aerospace industry has been witnessing continued growth post COVID-19. As per Accenture’s study, the Commercial Aerospace industry in 2023 is expected to showcase a growth of 11% in 2023.CNTs find application in both interior and exterior components within the aerospace sector, much like their usage in aerospace engineering. Flammability in an aircraft as a leading cause of accidents can be prevented by using flame-retardant plastics. Plastics are widely used in external as well as internal structures. Internal structures include cabins, cockpits, and cushion foams while external structures include rotor blades, flaps, fuselage and so on.

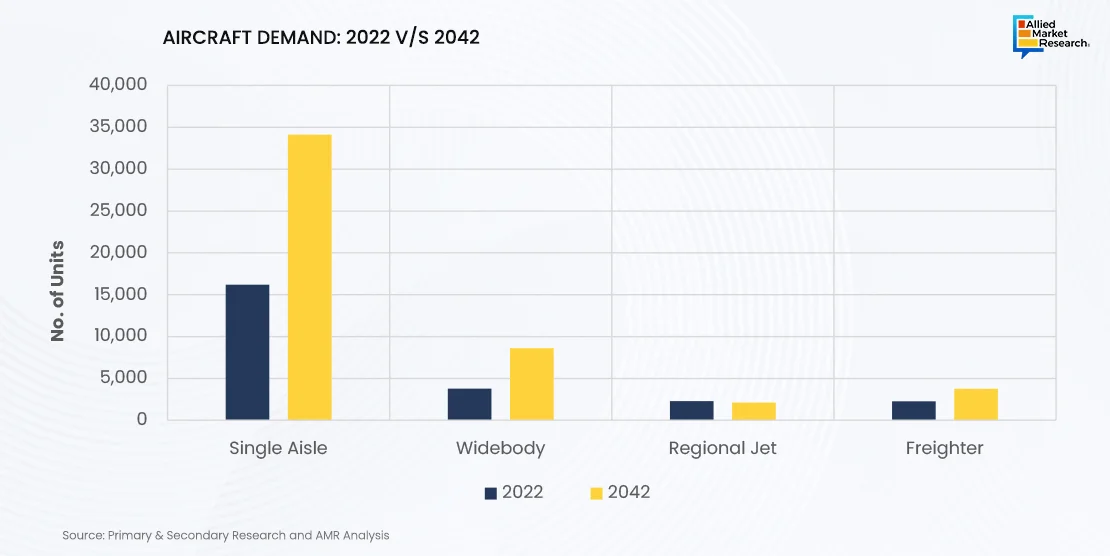

The above figure showcases the demand order for various aircraft types until 2042. According to Forecast International, Airbus received orders for 807 jets (gross orders) from 16 different airline companies. Turkish Airlines placed a massive order for 220 jets, which comprised of 150 A321neos and 70 A350s. Also, Indian carriers IndiGo and Air India placed orders with Airbus and Boeing for 500 and 470 jets, respectively.

Currently, CNTs are also utilized in composite materials on aircraft exteriors to mitigate damage and penetration risks from lightning strikes, with applications extending to various components like wings, fuselage, and rudder. Additionally, in the defense sector, CNTs find application in carbon foams. Hence, the aerospace and defense industry is experiencing a notable surge in demand for CNTs due to their exceptional properties, which enable the creation of lightweight components with enhanced capabilities. For instance, The Boeing Company has patented the use of carbon nanotubes for structural health monitoring of composites utilized in aircraft structures. It is expected that this technology will reduce the risk of an in-flight failure caused by structural degradation of an aircraft during its lifespan.

Strategic Approaches by CNT Manufacturers

Manufacturers are focusing on different strategic approaches to make CNT a lucrative option for various end-use industries. These companies undertake new product launch, expansion, R&D, merger & acquisition, agreements, and others to remain competitive in the industry. Below are some of the strategic approaches undertaken by them:

- In February 2024, Institute of Advanced Study in Science and Technology (IASST, India) conducted a new synthesis method for CNT production. In this method, CNT is directly synthesized on to glass substrate at 750°C using the Plasma Enhanced Chemical Vapour Deposition Technique (PECVD). This method is mainly useful in research, biomedical fields, and optoelectronics.

- In March 2024, CHASM Advanced Materials (U.S.) entered into an agreement with Ingevity (U.S.). As per the agreement, CHASM has developed CNT additives and other products which will be produced by Ingevity also, serving North America and Europe markets. This approach will reduce the import dependency on Asian CNT manufacturers, thus offering localized products.

CNT manufacturers do have the opportunity to expand their research initiatives into aerospace, chemical, electrical & electronics and automotive sectors. This expansion is driven by the goals of reducing costs, improving properties, and enhancing the flexibility of CNTs. Cost reduction will mostly come from using computer models, especially in processes and other AI tools. Progress in these areas will directly help the use of CNTs in different industries.

Allied Market Research delves into the intricacies of CNTs and other related products, as we aim to provide vendors with comprehensive insights into the evolving landscape. We provide in-depth details through highly curated reports that portray technological advancements, market trends, and government initiatives concerning the domain, which in turn help businesses integrate CNTs into their operations. To get more insights into the materials and chemicals domain, contact our specialists today!