Table Of Contents

- A Historical Perspective: Exploring the Evolution of Semiconductors

- Sustainability at the Core: Green Innovations in Semiconductors

- Energy-Efficient Manufacturing:

- Responsible Materials Management:

- Green Packaging Solutions:

- Sustainability in Supply Chains:

- Innovation in Green Technologies:

- Regulatory Compliance and Industry Standards:

- Personalized Solutions: Adapting Technology to Individual Needs

- Cutting-Edge Research and Development

- Case Study: Intel FPGAs in Smart Factory

- Closing Section

Sonia Mutreja

Koyel Ghosh

Semiconductor Industry 5.0: Instigating the Future of Technology

The semiconductor industry is about to enter a new era called Industry 5.0. This phase focuses on combining human intelligence with advanced technology to create systems that are efficient, sustainable, and tailored to individual needs. As global reliance on digital devices and smart systems is growing, the landscape of semiconductors is rapidly innovating to remain competitive. This involves embracing new technologies such as artificial intelligence, quantum computing, and nanotechnology, while also addressing challenges related to environmental impact and supply chain resilience. The future of global technology is expected to be defined by how well the industry can adapt.

The expanding industry is indispensable to Industry 5.0, supplying the essential components that enable the creation of intelligent and interconnected systems. The global semiconductor marketwas valued at $555.9 billion in 2021, and is projected to reach $1,033.5 billion by 2031, registering a CAGR of 6.21% from 2022 to 2031.Its expansion enables more advanced research and development, driving innovations that benefit the Industry 5.0 market by offering enhanced processing power, energy efficiency, and customization options.

A Historical Perspective: Exploring the Evolution of Semiconductors

The dawn of the semiconductor age: The semiconductor industry was born with the invention of the transistor in 1947, which marked a turning point in electronics. This ingenious development laid the foundation for integrated circuits (ICs) and revolutionized the way electronic devices were designed and manufactured. For instance, Bell Labs' Transistor, the creation of the first transistor by Bell Labs scientists John Bardeen, Walter Brattain, and William Shockley in 1947 was a significant event that paved the way for modern electronics.

This innovation, which won them the Nobel Prize in Physics in 1956, paved the way for future advances in semiconductor technology.

The rise and reign of Moore's law: In 1965, Gordon Moore predicted that the number of transistors on a chip would double roughly every two years. This prediction became a key goal for the semiconductor industry, leading to rapid advances in computing technology. For example, Intel's 8086 microprocessor, released in 1978, had 29,000 transistors and was a 16-bit chip. It laid the groundwork for the x86 architecture, which remains important for personal computers today.

The digital revolution: The 1980s and 1990s witnessed the rise of personal computing and the Internet, fueled by advancements in semiconductor technology. This era transformed how people connect, work, and communicate, paving the way for the digital age. Apple's Macintosh was launched in 1984., It was one of the first personal computers to feature a graphical user interface (GUI), making it accessible to a broader audience. The device's success was attributed to its Motorola 68000 microprocessor, which offered powerful computing capabilities.

Industry 4.0: Industry 4.0 introduced the concept of cyber-physical systems, IoT, and AI, driving the demand for advanced semiconductor solutions. The focus shifted toward developing chips capable of processing vast amounts of data, enabling smart devices and autonomous systems. NVIDIA's Volta GPU Architecture was introduced in 2017. It was designed to accelerate AI and deep learning workloads, providing a major performance improvement over the previous model. It exemplified the growing importance of semiconductors in enabling AI-driven applications.

Entering Industry 5.0: Industry 5.0 is shifting the focus to human-centered innovation, where technology supports and enhances human abilities and promotes teamwork between people and machines. In the semiconductor industry, this shift is leading to advancements that emphasize sustainability, customization, and collaboration. Technology is now used to boost human creativity and efficiency. For instance, Intel’s Smart Manufacturing Platform uses AI and IoT to optimize production, minimize downtime and defects, and improve worker productivity. This illustrates how working together with technology is transforming semiconductor manufacturing.

Sustainability at the Core: Green Innovations in Semiconductors

With growing environmental concerns, the semiconductor industry is embracing sustainable practices to minimize its ecological impact. Industry 5.0 emphasizes eco-friendly manufacturing, recycling initiatives, and the development of energy-efficient chips. For instance, GlobalFoundries' Green Chip Initiative, announced in April 2021, is committed to reducing its carbon footprint by adopting energy-efficient manufacturing processes and investing in renewable energy sources. The company's efforts align with Industry 5.0's focus on sustainability.

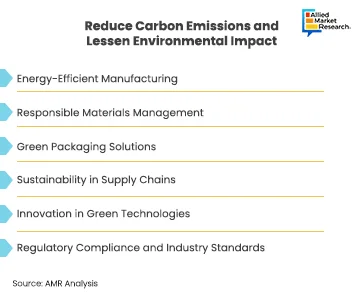

The industry is making significant efforts to transform its supply chain into a model of sustainability. The main goals are to reduce carbon emissions and lessen environmental impact. The industry is sailing across the journey as follows:

Energy-Efficient Manufacturing:

- Smart fab design: Semiconductor fabs are adopting intelligent layouts and advanced cooling systems to enhance operational efficiency and reduce energy consumption.

- Renewable energy integration: The industry is shifting toward renewable energy sources like solar and wind, reducing carbon footprints and achieving long-term cost savings.

Responsible Materials Management:

- Circular economy initiatives: Embracing a circular economy, the industry focuses on recycling water, chemicals, and electronic components to minimize waste and conserve resources.

- Ethical sourcing: Manufacturers are prioritizing responsible sourcing by closely examining supply chains to ensure ethical and sustainable material extraction and processing.

Green Packaging Solutions:

- Minimalistic designs: Eco-friendly, minimalistic packaging designs are being adopted to reduce environmental impact while maintaining product safety.

- Recyclable materials: Using recyclable packaging aligns with sustainability goals and appeals to environmentally conscious consumers.

Sustainability in Supply Chains:

- Emission tracking: Companies are investing in systems to track carbon emissions across supply chains, aiding regulatory compliance and building stakeholder trust.

- Supplier accountability: Collaboration with suppliers ensures adherence to environmental standards, supporting overall sustainability efforts.

Innovation in Green Technologies:

- Energy-efficient chips: The development of energy-efficient chips reduces power consumption in devices, supporting broader sustainability goals.

- Biodegradable electronics: Research into biodegradable electronic components aims to reduce electronic waste, offering promising sustainability advancements.

Regulatory Compliance and Industry Standards:

- Adherence to regulations: Manufacturers are meeting and exceeding environmental regulations to operate responsibly on a global scale.

- Industry Collaboration: Collaborative efforts between industry stakeholders and regulators are driving the development of comprehensive sustainability standards to support ongoing improvement.

Personalized Solutions: Adapting Technology to Individual Needs

Industry 5.0 emphasizes the creation of personalized solutions that cater to individual preferences and requirements. This trend drives the development of specialized semiconductor products for applications ranging from healthcare to consumer electronics. In June 2020, Qualcomm introduced the Snapdragon Wear 4100+ Platform for wearable devices, focusing on customizable features tailored to user needs like fitness tracking and health monitoring. This platform represents a major advancement in delivering customized semiconductor solutions to the industry.

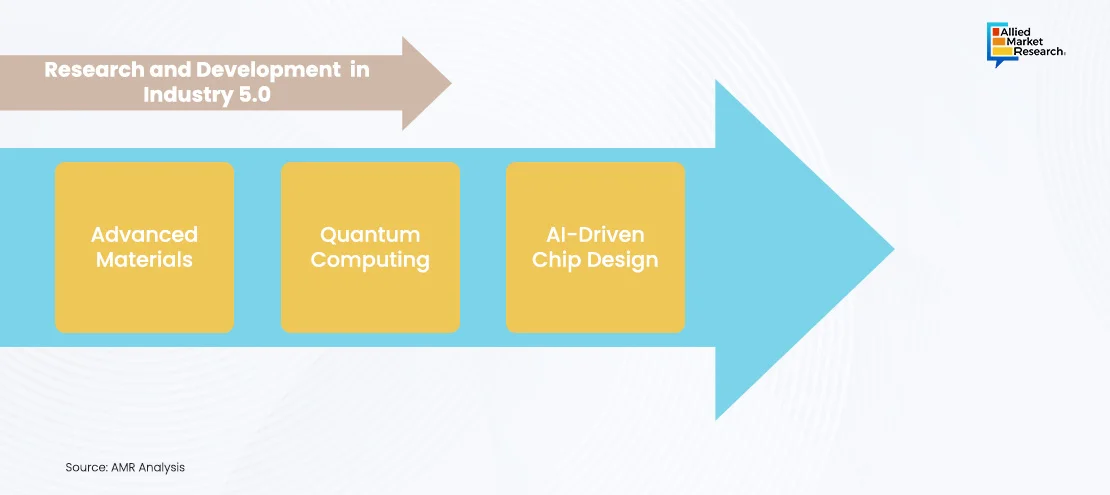

Cutting-Edge Research and Development

The semiconductor industry is focused on research and development to deal with the challenges of Industry 5.0, with companies investing in new materials, design methods, and manufacturing processes to drive innovation.

Advanced materials: The quest for smaller, faster, and more efficient chips drives research into new materials and manufacturing techniques. Innovations in materials science are enabling the development of next-generation semiconductors with enhanced properties. IBM's 2nm Chip Technologyunveiled in 2021, IBM's 2nm chip technology represents a breakthrough in semiconductor manufacturing. This technology promises improved performance and energy efficiency, paving the way for more powerful and sustainable computing solutions.

Quantum computing: Quantum computing holds the potential to solve problems that classical computers can’t. Semiconductor companies are exploring it to find new ways to improve computing and cryptography. Intel's Tangle Lake Quantum Chip is a superconducting processor with 49 qubits, created for quantum research to advance and explore new applications in quantum computing.

AI-Driven chip design: AI and machine learning are driving advancements in chip design and manufacturing. These technologies enable automated design processes, predictive maintenance, and enhanced quality control, improving efficiency and reducing costs. Cadence's Cerebrus Intelligent Chip Explorer, launched in June 2021, uses AI to speed up chip design and boost performance. It shows how AI is transforming semiconductor research and development.

Case Study: Intel FPGAs in Smart Factory

Background: Intel introduced its Field-Programmable Gate Arrays (FPGAs) to modernize smart factory operations, starting in 2019. The initiative aimed to address the growing need for high-performance and adaptable solutions in the rapidly evolving manufacturing sector. Smart factories, which use advanced technology and automation, need flexible computing solutions to manage intricate processes. Intel® recognized that FPGAs, known for their adaptability and reconfigurability, could improve the capabilities of smart factories.

Challenges: Smart factories have challenges like processing data and signals quickly and working with different communication systems. Traditional hardware often can't keep up because it's not flexible enough. As manufacturing is getting data-heavy, there's a growing need for faster and more adaptable solutions. Combining different communication systems and handling multiple tasks at once is also tough for older systems.

Solution: To address these challenges, Intel deployed its FPGAs, which offer reconfigurability and high performance. FPGAs are customizable chips that can be programmed for specific tasks like real-time processing and high-speed signal handling. In smart factories, Intel® FPGAs were used for tasks such as real-time monitoring, process control, and data collection. This flexibility allowed manufacturers to adapt their systems to changing needs, integrate different communication protocols, and improve efficiency.

Benefits: The deployment of Intel FPGAs in smart factories led to several key benefits. First, the ability to process data in real-time significantly improved operational efficiency and responsiveness. This capability allowed for faster decision-making and more precise control over manufacturing processes. Second, the flexibility of FPGAs enabled easy adaptation to new technologies and requirements, strengthening innovation and enabling manufacturers to stay competitive in a rapidly changing market. Overall, Intel® FPGAs offer a powerful solution for improving smart factory operations, boosting productivity, and ensuring systems can keep up with technological advancements.

Closing Section

In conclusion, Industry 5.0 is revolutionizing the semiconductor industry by combining human creativity with cutting-edge technology, focusing on sustainability and personalization. This shift isn't just about technological progress; rather, it's about making tech more efficient and eco-friendlier. With innovations in quantum computing, AI, and green practices, the industry is setting new standards, shaping a smarter, greener future for global technology.

Allied Market Research serves as a trusted partner for vendors in the semiconductor industry 5.0 market, providing tailored strategies to embrace cutting-edge technologies and prioritizing ethical sourcing and green initiatives, the industry aims to address global challenges and meet the demands of an increasingly interconnected world. With AMR's expertise on board, businesses can identify opportunities, assess market demand, and foster innovation in industry 5.0. This enables companies to invest in research and development and produce semiconductor products using sustainable methods.

For detailed information on the latest technologies, innovations, and market dynamics shaping the domain of semiconductors, contact our specialists today!