Screw Compressor Market Research, 2032

The global screw compressor market was valued at $10.8 billion in 2022, and is projected to reach $18.9 billion by 2032, growing at a CAGR of 5.8% from 2023 to 2032.

Report Key Highlighters:

- The screw compressor market analysis study covers 20 countries. The research includes a segment analysis of each country in terms of value ($million) for the projected period 2023-2032.

- The study incorporated research methodology aims to present a comprehensive outlook on global markets and aid key stakeholders & players in making well-informed decisions to accomplish their ambitious growth goals.

- Over 1,500 product literatures, industry statements, annual reports, and other comparable materials from major screw compressor industry participants were reviewed to gain a better understanding of the market.

- The screw compressor market is fragmented, with several players including Atlas Copco AB, Kobelco, Ingersoll Rand, Keser Kompressoren SE, Gardner Denver, Sullair, Bge Kompressoren, ELGI Equipment Limited, Quincy Compressor, and Bauer Kompressoren GmbH. Also tracked key strategies such as acquisitions, product launches, developments, partnership, mergers, expansion etc. of the players operating in the screw compression industry.

Screw compressors stand as essential components in various industries and play a critical role in efficiently compressing air and gas. These systems find widespread use in diverse applications, showcasing adaptability and scalability crucial to industrial operations, whether in manufacturing facilities, automotive plants, or oil and gas refineries.

One of the primary advantages of screw compressors lies in their efficiency in ensuring continuous and consistent compressed air supply. These compressors adeptly handle varying demands, adjusting output to accommodate fluctuating usage patterns in different industrial settings. Their adaptability to diverse environments and operational demands, from small-scale production to large-scale industrial applications, underscores their versatility within the energy and manufacturing sectors.

Moreover, screw compressors significantly contribute to maintaining operational stability by ensuring a steady supply of compressed air or gas. Their rapid response to changing demands and their capacity to maintain a consistent output facilitate smooth and uninterrupted industrial processes, essential for operational efficiency across multiple industries.

The growth of the screw compressor market is driven by escalating demands for compressed air in developed and emerging economies, especially in manufacturing hubs. These compressors are indispensable in optimizing operational efficiency and productivity across various industrial sectors, reflecting their role as a vital component of industrial operations.

However, challenges persist in the adoption of screw compressors, particularly in environmental impact and operational efficiency. Some older compressor systems contribute to environmental concerns through emissions or inefficient energy consumption. Addressing these challenges requires a focus on sustainable and eco-friendly technologies, promoting cleaner energy consumption and enhancing the compressors' environmental performance.

Furthermore, the efficient operation and maintenance of screw compressors demand specialized technical expertise. Access to skilled personnel for reliable and efficient operation in regions with limited resources poses a challenge. To mitigate this, investing in training programs and building local capacity becomes imperative for sustainable and effective operation.

Despite these challenges, the screw compressor market holds immense growth potential. Their efficiency and adaptability are pivotal in ensuring optimal compressed air supply, making them an indispensable solution for various industrial sectors. As industries demand cleaner and more sustainable operational practices, the development and innovation of screw compressors will play a crucial role in meeting these evolving needs.

The screw compressor market scope is segmented on the basis of type, stage, technology, end user, and region. By type, the market is divided into oil free and oil injected. By stage, the market is segregated into single stage and multistage. On the basis of technology, it is bifurcated into portable and stationary. On the basis of end user, it is segregated into oil and gas, food and beverage, energy and power, chemicals and petrochemicals, and others. Region-wise, the screw compressor market trends are analyzed across North America, Europe, Asia-Pacific, and LAMEA.

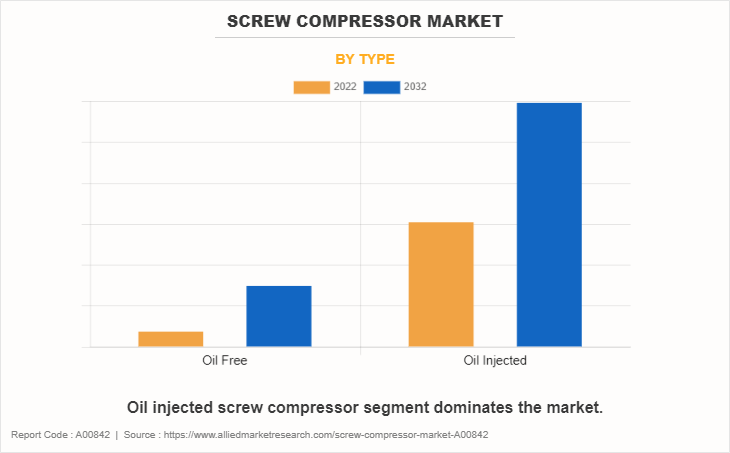

Based on type, the oil injected segment held the highest market share in 2022, accounting for nearly three-fourths of the global screw compressor market size, and is estimated to maintain its leadership status throughout the forecast period. The market for oil-free screw compressors is witnessing substantial growth driven by several key trends and factors. Heightened environmental concerns and tightening regulations have spurred industries to seek eco-friendly solutions, aligning perfectly with oil-free compressors that eliminate the risk of oil contamination in compressed air. This demand is further amplified in sensitive sectors like pharmaceuticals, food and beverage, electronics, and healthcare, where the necessity for entirely oil-free compressed air to prevent contamination is critical.

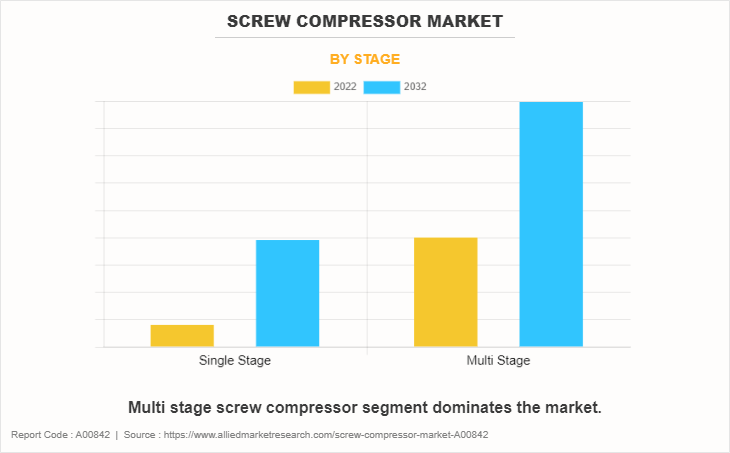

Based on stage, multi stage segment held the highest market share in 2022, accounting for nearly two-thirds of the global screw compressor market share, and is estimated to maintain its leadership status throughout the forecast period. Integration of smart technologies is transforming the landscape through remote monitoring, predictive maintenance, and automation, optimizing performance, and minimizing downtime

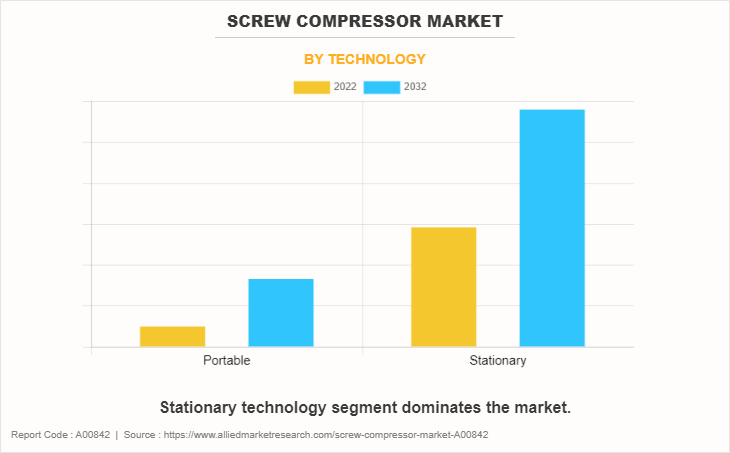

Based on the technology, the stationary segment held the highest market share in 2022, accounting for nearly three-fourths of the global screw compressor market revenue, and is estimated to maintain its leadership status throughout the forecast period. The portable screw compressor market is experiencing robust growth driven by diverse factors and evolving industry demands. With industries like construction, mining, and oil and gas seeking greater mobility, the need for portable equipment remains high. Technological strides in compressor design, prioritizing efficiency, and reduced emissions, are reshaping market preferences.

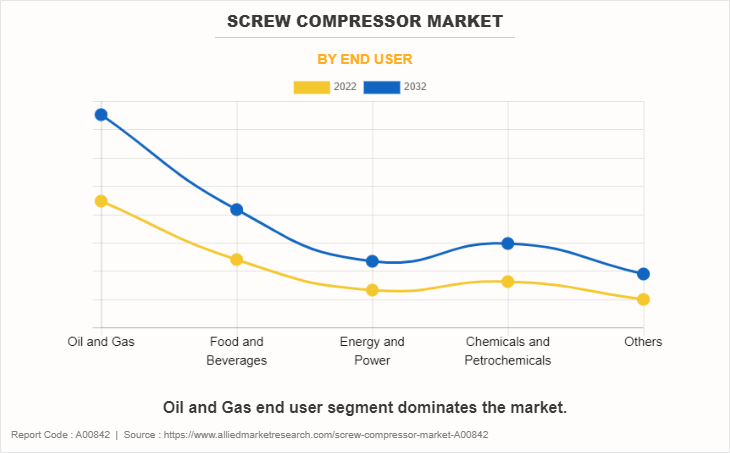

Based on the end user, oil and gas held the highest market share in 2022, accounting for more than two-fifths of the global screw compressor market revenue, and are estimated to maintain their leadership status throughout the forecast period. The pharmaceutical industry's pursuit of precision and quality in manufacturing fuels a growing need for reliable and efficient screw compressors. Innovations like oil-free designs and energy-efficient technology align with the industry's push for cleanliness and sustainability, creating opportunities for compressor manufacturers.

Based on region, Asia-Pacific held the highest market share in terms of revenue in 2022, accounting for nearly two-fifths of the global screw compressor market revenue, and is likely to dominate the screw compressor market forecast. The screw compressor industry in the Asia-Pacific region is experiencing a dynamic shift driven by several key trends and growth factors. Rapid industrialization in powerhouse economies like China and India is propelling demand across diverse sectors such as manufacturing, oil & gas, petrochemicals, and automotive, while an increase in emphasis on energy efficiency aligns with the region's sustainability goals, favoring screw compressors for their higher efficiency.

Regional Development of Screw Compressors:

- In North America, screw compressors are integral to industrial operations across various sectors. In the U.S., these compressors are extensively utilized in manufacturing, automotive, and oil and gas industries. Stricter environmental regulations have encouraged the adoption of more efficient compressor technologies, aligning with sustainability objectives.

- Within Europe, screw compressors are significant in industrial processes, especially in regions prioritizing eco-friendly practices and renewable energy. European countries are exploring cleaner and more energy-efficient options for compressors to meet stringent environmental goals.

- In the Asia-Pacific, countries with diverse industrial operations are adopting screw compressors for their efficiency and adaptability. Nations like China and India utilize these compressors extensively across manufacturing and automotive sectors, seeking enhanced operational efficiency.

- Latin American countries, including Brazil, recognize the importance of screw compressors in various industrial applications. These compressors play a crucial role in ensuring efficiency across manufacturing, construction, and oil and gas sectors, where emphasis is placed on environmentally conscious practices.

- In Africa, screw compressors are pivotal in addressing industrial demands across sectors. These systems are utilized in diverse settings, contributing to operational efficiency in manufacturing and oil and gas industries, particularly in areas with limited access to traditional energy sources.

The development and utilization of screw compressors significantly contribute to industrial optimization across different regions. Their adaptability and efficiency cater to diverse industrial demands, enabling sustainable and optimized operational practices worldwide. As industries advance, innovations in screw compressor technology will be pivotal in meeting evolving operational needs and environmental considerations.

Competitive analysis and profiles of the major screw compressor market players, such as Atlas Copco AB, Kobelco, Ingersoll Rand, Keser Kompressoren SE, Gardner Denver, Sullair, Bge Kompressoren, ELGI Equipment Limited, Quincy Compressor, and Bauer Kompressoren GmbH. are focusing their investment on technologically advanced, cost-effective, and more secure products and solutions for various applications.

Key Benefits For Stakeholders

- This report provides a quantitative analysis of the market segments, current trends, estimations, and dynamics of the screw compressor market analysis from 2022 to 2032 to identify the prevailing screw compressor market opportunities.

- The market research is offered along with information related to key drivers, restraints, and opportunities.

- Porter's five forces analysis highlights the potency of buyers and suppliers to enable stakeholders make profit-oriented business decisions and strengthen their supplier-buyer network.

- In-depth analysis of the screw compressor market segmentation assists to determine the prevailing market opportunities.

- Major countries in each region are mapped according to their revenue contribution to the global market.

- Market player positioning facilitates benchmarking and provides a clear understanding of the present position of the market players.

- The report includes the analysis of the regional as well as global screw compressor market trends, key players, market segments, application areas, and market growth strategies.

Screw Compressor Market Report Highlights

| Aspects | Details |

| Market Size By 2032 | USD 18.9 billion |

| Growth Rate | CAGR of 5.8% |

| Forecast period | 2022 - 2032 |

| Report Pages | 280 |

| By Type |

|

| By Stage |

|

| By Technology |

|

| By End User |

|

| By Region |

|

| Key Market Players | ELGI EQUIPMENTS LIMITED, Gardner Denver, BAUER KOMPRESSOREN GmbH., Boge Kompressoren, Atlas Copco AB, Kaeser Kompressoren SE, Quincy Compressor, Kobelco, Ingersoll Rand, Sullair |

Analyst Review

From the perspective of CXOs and industry leaders, the screw compressor market reflects a dynamic landscape poised for significant growth and evolution. These compressors play an instrumental role across diverse sectors, offering efficient compressed air solutions vital to industrial operations worldwide. The market's trajectory is fueled by persistent demand for reliable, energy-efficient compressors catering to sectors ranging from manufacturing and automotive to oil & gas and pharmaceuticals.

Screw compressors are valued for their superior energy efficiency, driving operational cost savings, and aligning with the industry's focus on sustainability and reduced carbon footprints. Their adaptability and versatility make them indispensable across a spectrum of applications, ensuring consistent compressed air supply essential for seamless industrial processes.

The industry's commitment to technological advancements, pushing for smarter, IoT-enabled compressors that offer improved performance, automation, and predictive maintenance capabilities drives market growth. However, challenges such as initial capital investment and the necessity for comprehensive technical support and training to optimize the performance and longevity of these systems persist.

The screw compressor market presents an optimistic outlook with vast opportunities for expansion across global regions, including North America, Europe, Asia-Pacific, and the Middle East. Despite challenges, the industry's dedication to innovation, energy efficiency, and customer-centric solutions positions screw compressors as integral components in modern industrial processes, anticipating sustained growth and market relevance.

Variable Speed Drive (VSD) Screw Compressors, Energy-Efficient Screw Compressor Technology, Oil-Free Screw Compressors, IoT Integration for Smart Monitoring and Maintenance, Increased Demand in Emerging Markets are the upcoming trends of Screw Compressor Market in the world.

Oil and Gas is the leading application of Screw Compressor Market.

Asia-Pacific is the largest regional market for Screw Compressor.

$18.9 billion is the estimated industry size of Screw Compressor in 2032.

some of the top companies dominating the screw compressor market include: Atlas Copco Ingersoll Rand Gardner Denver Kaeser Kompressoren SE Sullair BOGE ELGi Equipments Limited Kobe Steel Ltd. (Kobelco)

Loading Table Of Content...

Loading Research Methodology...