Silicone Coatings Market Research - 2032

The global silicone coatings market size was valued at $5.3 billion in 2022, and is projected to reach $10.1 billion by 2032, growing at a CAGR of 6.7% from 2023 to 2032. Silicone coatings are compositions based on silicones, a synthetic polymer family consisting of silicon, oxygen, carbon, and hydrogen atoms. Unlike organic polymers, which are carbon-based, silicones include silicon into their molecular structure, giving the resulting materials unique characteristics. Silicones are well-known for their remarkable heat resistance, flexibility, and resistance to environmental conditions. The adaptability of silicone coatings arises from their ability to be customized for various applications by adjusting their molecular structure and adapting their properties to meet a number of needs. The flexibility and suppleness of silicone coatings contribute to their lifespan and resistance to cracking and peeling, especially in dynamic environments. They are self-cleaning due to their low surface tension, making them excellent for applications that need cleanliness and minimum maintenance.

![]()

Highlights of the Report

- The report provides exclusive and comprehensive analysis of the global silicone coatings market trends along with the silicone coatings market forecast.

- The report elucidates the silicone coatings market opportunity along with key drivers, and restraints of the market. It is a compilation of detailed information, inputs from industry participants and industry experts across the value chain, and quantitative and qualitative assessment by industry analysts.

- Porter’s five forces analysis helps analyze the potential of the buyers & suppliers and the competitive scenario of the market for strategy building.

- The report entailing the silicone coatings market analysis maps the qualitative sway of various industry factors on market segments as well as geographies.

- The data in this report aims on market dynamics, trends, and developments affecting the silicone coatings market growth.

Silicone coatings are effective at providing thermal stability. They can tolerate high and low temperatures without damaging their structural integrity. Because of its thermal resilience, silicone coatings are suited for a broad range of applications, including aerospace, automotive, and industrial situations where temperature variations are common. The ability of silicone coatings to sustain performance at severe thermal conditions improves product and structural durability and efficiency. Another noteworthy benefit of silicone coatings is their pliability and suppleness. These coatings may move with the underlying substrates without breaking or peeling. Because of their flexibility, silicone coatings are an excellent choice for construction applications where structures are prone to structural movements caused by reasons such as earthquake. Silicone resins are also exceptionally flexible and adherent. Their elasticity lets them to expand and contract in response to substrate movement, reducing fractures and delamination. Because of this flexibility, silicone coatings are particularly useful for usage on flexible materials such as textiles, delivering a long-lasting protective layer without affecting the material's fundamental qualities. In addition to physical durability, silicone coatings provide high water repulsion in roof coating. This hydrophobic nature not only protects surfaces from water damage but also inhibits the formation of mold and mildew. This property is especially important in construction applications, where moisture resistance is critical to maintaining the structural integrity of structures and infrastructure.

The downside of silicone coatings industry is that they provide an adherence issue. Achieving good adherence to some surfaces might be difficult, limiting the coating's efficacy in specific applications. Due to the intrinsic qualities of silicone, adhesion challenges may emerge, making it difficult for the coating to adhere successfully with certain surfaces. Proper surface preparation and the use of proper primers are critical in mitigating this difficulty, but it remains a factor that need to be carefully considered. In addition, silicone coatings may be incompatible with some solvents and chemicals. While silicone is typically resistant to a wide variety of contaminants, exposure to certain compounds might cause coating deterioration or loss of integrity. It is critical to examine the chemical environment to which the coating will be exposed and confirm that the silicone formulation chosen is compatible with the chemicals present. The comparatively slow drying period of some silicone coatings might be a disadvantage in terms of application and curing. This property is expected to hinder the efficiency of industrial procedures that need short turnaround times. Furthermore, external factors like temperature and humidity might alter the curing process, necessitating careful monitoring and control during application to ensure maximum performance.

The adaptability of silicone coatings across different materials is a key aspect leading to the rise in demand for silicone coating. Silicone coatings are suitable for a variety of surfaces, including metals, plastics, glass, and fabrics, making them a versatile choice for a wide range of surfaces. This versatility enhances their capabilities in a variety of sectors, spurring innovation and encouraging producers to investigate new applications. Silicone coatings' ability to produce a smooth and homogeneous layer on a variety of substrates not only improves their visual appeal but also adds to enhanced performance, making them a favored choice for industries seeking multi-surface compatibility. The global emphasis on energy efficiency and sustainability has boosted demand for silicone coatings in the construction industry, where they help to design energy-efficient structures. Silicone coatings serve as good weather barriers, preventing water entry and air leakage. Certain silicone coatings' reflective qualities also help to reduce solar heat gain, supporting energy saving by improving building thermal performance. Silicone coatings are emerging as a key tool in attaining energy efficiency and environmental goals as the construction industry embraces green building methods. Furthermore, ease of application and variety in formulation add to the appeal of silicone coatings for both producers and end users. Silicone coatings can be applied in a variety of ways, including spraying, dipping, and brushing, providing for greater production flexibility.

Segments Overview:

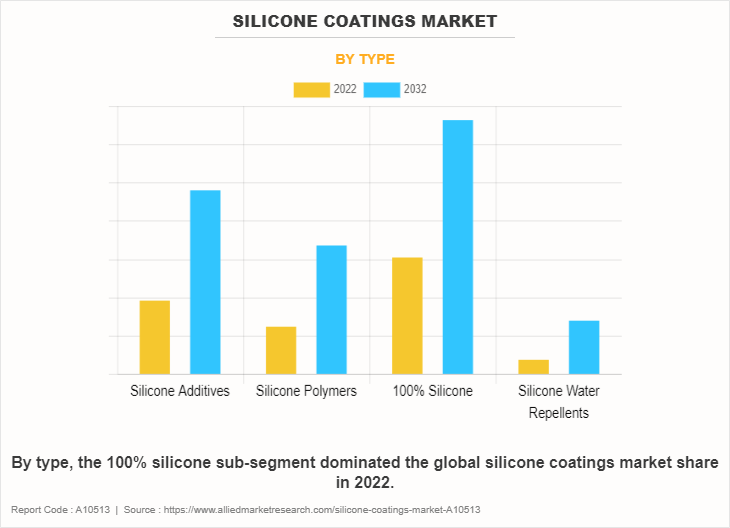

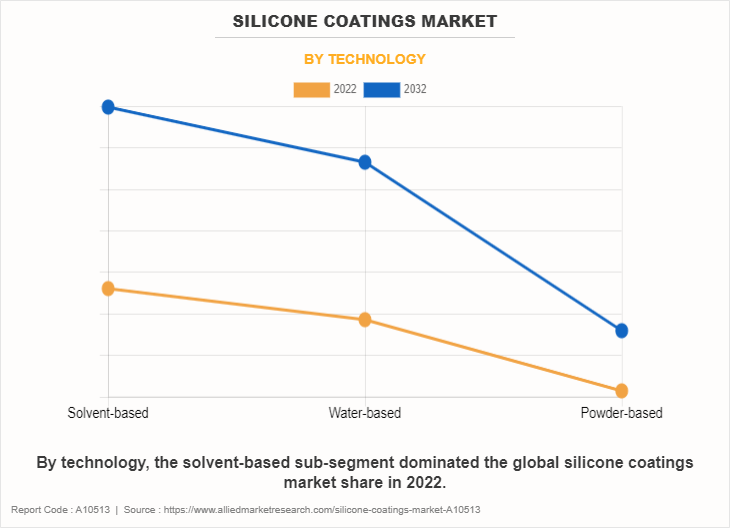

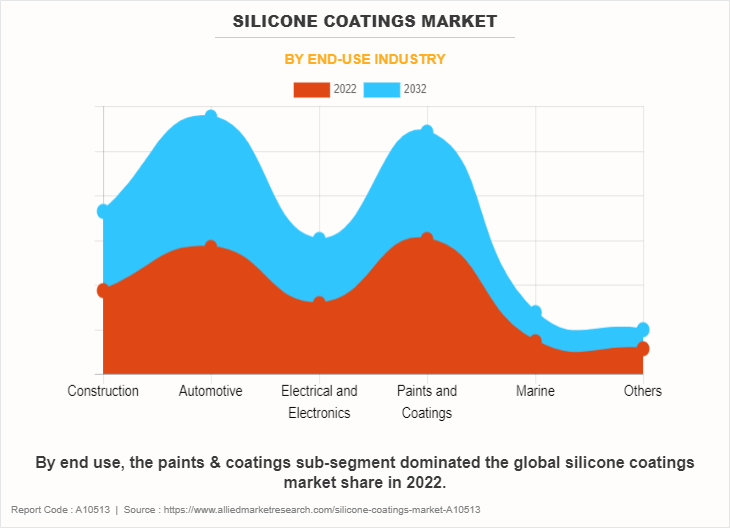

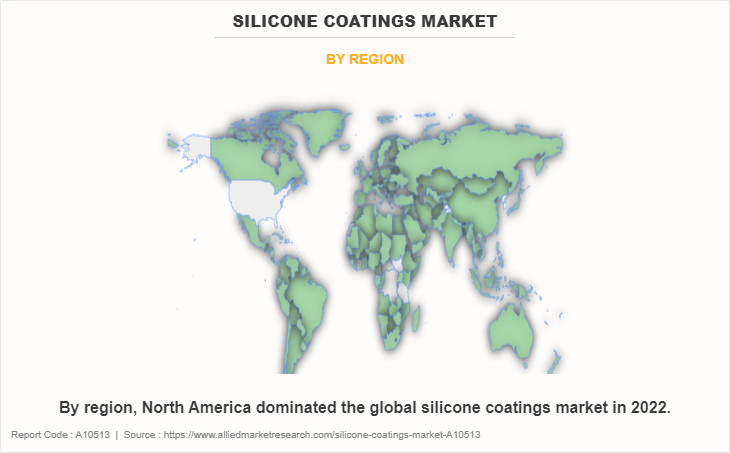

The silicone coatings market is segmented on the basis of type, technology, end use, and region. By type, the market is divided into silicone additives, silicone polymers, 100% silicone, and silicone water repellents. By technology, the market is classified into solvent-based, water-based, and powder-based. By end use, the market is classified into construction, automotive, electrical & electronics, paints & coatings, marine, and others. By region, the market is analyzed across North America, Europe, Asia-Pacific, and LAMEA.

The silicone coatings market is segmented into Type, Technology and End-use Industry.

Silicone Coatings Market By Type

By type, the 100% silicone sub-segment dominated the global silicone coatings market share in 2022. Because of their adaptability, 100% silicone coatings are applied to a wide range of surfaces and substrates. Silicone coatings attach effortlessly, offering a uniform and effective protective layer whether applied on roofs, walls, industrial equipment, or even electronic components. Because of this versatility, 100% silicone coatings are ideal for a wide range of sectors, from construction to automotive and electronics, providing a versatile solution for a variety of coating demands. The unusual molecular structure of silicone allows for breathability while preserving remarkable moisture resistance. This feature is especially useful in situations where moisture ingress might be a problem, such as roofing applications. 100% silicone coatings create a permeable barrier that allows water vapor to leave while preventing liquid water from entering. This breathability enhances the lifespan of buildings by reducing the risk of failure. The use of 100% silicone coatings is well-known for its ease of use and efficiency. These coatings may be applied in a variety of ways, including spraying, rolling, or brushing, making the procedure accessible to both experts and self-employed.

Silicone Coatings Market By Technology

By technology, the solvent-based sub-segment dominated the global silicone coatings market share in 2022. Solvent-based silicone coatings have exceptional thermal stability, making them appropriate for applications involving temperature changes. These coatings can endure high temperatures without losing their protective characteristics, making them ideal for use in industrial environments where equipment and buildings may be subjected to high temperatures. The capacity of solvent-based silicone coatings to withstand heat deterioration extends their life and assures constant performance under adverse situations. Another significant benefit of solvent-based silicone coatings is their good adherence to a variety of substrates. These coatings attach well to metal, concrete, and brick surfaces, providing a cohesive connection that improves overall protection. Solvent-based silicone coatings' strong adherence adds to their flexibility, allowing them to be applied to a wide range of substrates in a variety of applications. This property is especially useful in building projects where various materials require dependable protection against environmental conditions. Solvent-based silicone coatings provide self-leveling capabilities in addition to being protective. This results in a smooth and uniform application and an aesthetically attractive finish. These coatings' self-leveling function reduces the possibility of uneven surfaces and coating thickness changes, resulting in a uniform and professional look.

Silicone Coatings Market By End Use

By end use, the paints & coatings sub-segment dominated the global silicone coatings market share in 2022. Environmental concerns have increased in the paints & coatings sector, driving demand for eco-friendly and sustainable solutions. Silicone coatings are consistent with this trend since they are typically low in volatile organic compounds (VOCs), contributing to a lower environmental effect. VOCs are known to contribute to air pollution and have negative health impacts. Silicone coatings' low VOC level makes them a more ecologically responsible alternative, meeting regulatory criteria and addressing the rising customer desire for sustainable products. The great heat resistance of silicone coatings is widely recognized. This unique characteristic aids in the preservation of structural integrity and performance under high-temperature conditions. Silicone coatings are increasingly being utilized to increase the heat resistance of surfaces in areas where high temperatures are common, such as automotive, aerospace, and industrial manufacturing. This feature makes silicone coatings a popular choice for applications requiring heat stability, further increasing its demand in the paints & coatings industry. Continuous R&D in formulation technologies has led in advancements in silicone coatings.

Silicone Coatings Market By Region

By region, North America dominated the global silicone coatings market in 2022. The extraordinary durability and weather resistance of silicone coatings is one of the key driving forces behind their extensive use in North America. Silicone-based coatings are extremely resistant to adverse environmental conditions such as UV radiation, intense temperatures, and wetness. Because of this, they are an excellent choice for outdoor applications such as architectural coatings and automobile paints where contact to the environment is unavoidable. The necessity for coatings that can survive a wide range of weather conditions has greatly boosted demand for silicone coatings in places with different climates, such as North America. The usage of silicone coatings in the automobile sector in North America has also increased. Silicone-based paints and coatings have great adhesion, flexibility, and corrosion resistance, making them perfect for protecting cars from the rigors of regular usage as well as exposure to a variety of weather conditions. Furthermore, the automobile industry's increasing emphasis on lightweight materials and fuel efficiency has resulted in greater use of silicone coatings due to their ability to contribute to reduced vehicle weight while preserving durability.

Competitive Landscape:

The key players profiled in silicone coatings market report include Evonik Industries AG, Wacker Chemie AG, Carboline Company, OMG Borchers GmbH, Shin-Etsu Chemical Co., Ltd., Momentive Performance Materials Inc, DOW Corning Corporation, ACC Silicones Ltd., MAPEI SpA, and Sika AG. Product innovation & development and market expansion are common strategies followed by major market players. For instance, on June 29, 2023, Elkem launched new UV LED curable silicone solutions, Silcolease UV LED Series. As an alternative to mercury vapor curing lamps, UV LED technology has developed as a potential solution for radiation curing silicone chemistry at specified wavelengths.

Key Benefits For Stakeholders

- This report provides a quantitative analysis of the market segments, current trends, estimations, and dynamics of the silicone coatings market analysis from 2022 to 2032 to identify the prevailing silicone coatings market opportunities.

- The silicone coatings market research is offered along with information related to key drivers, restraints, and opportunities.

- Porter's five forces analysis highlights the potency of buyers and suppliers to enable stakeholders make profit-oriented business decisions and strengthen their supplier-buyer network.

- In-depth analysis of the silicone coatings market segmentation assists to determine the prevailing market opportunities.

- Major countries in each region are mapped according to their revenue contribution to the global market.

- Market player positioning facilitates benchmarking and provides a clear understanding of the present position of the market players.

- The report includes the analysis of the regional as well as global silicone coatings market trends, key players, market segments, application areas, and market growth strategies.

Silicone Coatings Market Report Highlights

| Aspects | Details |

| Market Size By 2032 | USD 10.1 billion |

| Growth Rate | CAGR of 6.7% |

| Forecast period | 2022 - 2032 |

| Report Pages | 295 |

| By Type |

|

| By Technology |

|

| By End-use Industry |

|

| By Region |

|

| Key Market Players | Carboline Company, Shin-Etsu Chemical Co., Ltd., mapei spain, s.a., Wacker Chemie AG, Dow Corning Corporation, ACC Silicones Ltd., Evonik Industries AG, OMG Borchers GmbH, Momentive Performance Materials Inc., Sika AG |

Construction companies are the major customers in the global silicone coating market.

The report provides an extensive qualitative and quantitative analysis of the current trends and future estimations of the global silicone coating market from 2022 to 2032 to determine the prevailing opportunities.

Silicone coatings play a crucial role in the automotive industry for exterior finishes, protecting surfaces from environmental elements, which is expected to drive its adoption in the upcoming years.

Increase in use of bio-based silicone coatings, rise in healthcare and biomedical applications, and surge in demand for smart coatings and responsive functionalities are factors anticipated to drive the global silicone coating market.

The silicone coating market size is expected to grow due to durability and protective properties of silicone coating. In addition, the demand is driven by its water repellency and anti-corrosive properties.

The major growth strategies adopted by the silicone coating market players are product innovation & development and market expansion.

Asia-Pacific will provide more business opportunities for the global silicone coating market in the future.

Evonik Industries AG, Wacker Chemie AG, Carboline Company, OMG Borchers GmbH, Shin-Etsu Chemical Co., Ltd., Momentive Performance Materials Inc, DOW Corning Corporation, ACC Silicones Ltd., MAPEI SpA, and Sika AG., are the major players in the silicone coating market.

The 100% silicone sub-segment of the type segment acquired the maximum share of the global silicone coating market in 2022.

Loading Table Of Content...

Loading Research Methodology...