Slewing Bearing Market Research, 2033

The global slewing bearing market size was valued at $4.3 billion in 2023, and is projected to reach $7.2 billion by 2033, growing at a CAGR of 5.3% from 2024 to 2033.

Market Introduction and Definition

A slewing bearing, also known as a slewing ring or turntable bearing, is a specialized bearing designed to handle large axial, radial, and moment loads simultaneously, often required in applications where heavy, rotating components must be supported and allowed to move smoothly. As compared to standard bearings, slewing bearings are typically large in diameter and robustly constructed to support the rotation or oscillation of heavy machinery parts. They consist of an inner ring, an outer ring, rolling elements such as balls or rollers, and spacers, and are commonly used in equipment such as cranes, excavators, wind turbines, and rotating platforms, where both stability and rotational capability under significant load are essential.

Key Takeaways

- The slewing bearing market report covers 20 countries. The research includes a segment analysis of each country in terms of value ($billion) for the projected period 2023-2033.

- More than 1,500 product literatures, industry releases, annual reports, and other such documents of major slewing bearing industry participants along with authentic industry journals, trade associations' releases, and government websites have been reviewed for generating high-value industry insights.

- The study integrated high-quality data, professional opinions and analysis, and critical independent perspectives. The research approach is intended to provide a balanced view of global markets and to assist stakeholders in making educated decisions to achieve their most ambitious growth objectives.

Key Market Dynamics

Technological innovations include advancements in materials, lubrication technologies, and enhanced manufacturing processes, which have improved the performance, durability, and efficiency of slewing bearings. High-strength materials, such as advanced steels and composites, have led to slewing bearings that withstand heavier loads and harsh environments, that make them essential for applications in industries such as renewable energy, construction, and mining. In addition, the integration of smart technologies, such as sensors and IoT capabilities, into slewing bearings allows for real-time monitoring of bearing conditions. This predictive maintenance capability reduces downtime and maintenance costs, which is highly valued in sectors that rely on continuous operation, such as wind energy and heavy machinery. Furthermore, innovations in lubrication systems have extended the service life of slewing bearings by reducing friction and wear, leading to increased adoption across various industrial applications. All these factors are expected to drive the demand for the slewing bearing market forecast.

However, the production of slewing bearings involves complex processes that require advanced machinery, skilled labor, and high-quality raw materials. These components and the associated manufacturing processes lead to increased costs, making the final product expensive. This cost burden is further exacerbated by stringent quality control measures, as slewing bearings are critical components in various heavy-duty applications such as wind turbines, construction machinery, and industrial equipment. Moreover, the high costs are also influenced by the need for customization in slewing bearings, as different applications require specific designs and specifications. The custom manufacturing process adds to the cost and extends production timelines, which delay market entry and reduce competitiveness. In addition, the fluctuating prices of raw materials such as steel and other alloys contribute to the unpredictability of manufacturing costs, making it difficult for manufacturers to maintain consistent pricing. All these factors hamper the slewing bearing market growth during the forecast period.

The development of new materials, such as advanced composites, ceramics, and high-performance alloys, has enhanced the durability, strength, and efficiency of slewing bearings. These materials offer superior resistance to wear, corrosion, and extreme temperatures, that make them ideal for demanding applications in industries such as wind energy, construction, and mining. In addition, innovative techniques such as additive manufacturing (3D printing) allow for more precise and complex designs, enabling the production of custom bearings tailored to specific applications. Furthermore, the integration of smart technologies, such as sensors and monitoring systems, into slewing bearings is another emerging trend. These smart bearings can provide real-time data on performance, wear, and potential failures, allowing for predictive maintenance and reducing the risk of unexpected breakdowns. All these factors are anticipated to offer new growth opportunities for the global slewing bearing market forecast period.

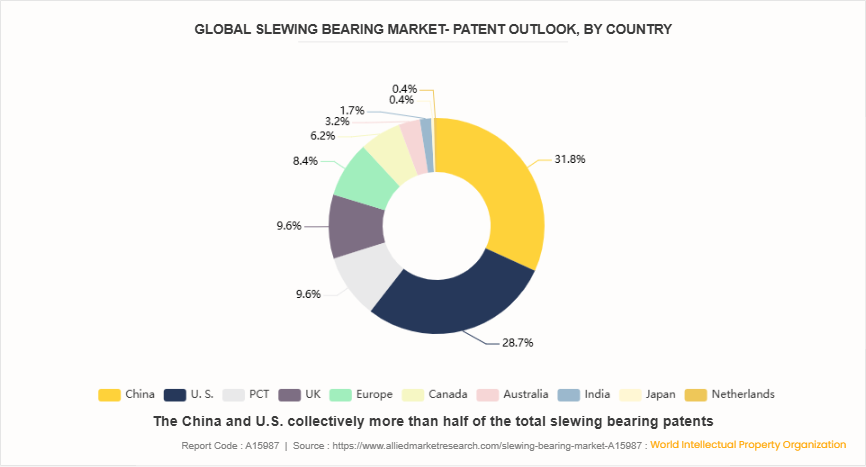

Patent Analysis of Slewing Bearing Market, By Country

The China and U.S. collectively more than half of the total slewing bearing patents that indicate strong innovation and investment in this technology in China countries. This suggests fierce competition and a significant focus on slewing bearing R&D in these leading economies. China has the highest patent filed those accounts for 31.8% of the total global patents related to the slewing bearing market. Europe and PCT, although holding smaller percentages of slewing bearing patents individually, collectively contribute to the overall Asian dominance in slewing bearing innovation. This reflects the region's strong presence in materials science and engineering R&D.

Market Segmentation

The slewing bearing market is segmented into type, gear rings, gear type, application, and region. Based on type, the market is classified into tapered roller bearing, roller bearings, ball bearings, combined roller and ball bearings. By gear ring, the market is classified into ball and roller. By gear type, the market is divided into internal gear, ungeared, external gear. By application, the market is divided into heavy-duty machinery, wind turbines, mining equipment, robotics equipment, medical diagnostic equipment, and others. Region-wise the market is analyzed across North America, Europe, Asia-Pacific, and LAMEA.

Regional Market Outlook

Rapid industrialization and urbanization. Countries such as China, India, and Japan are experiencing significant infrastructure development, including the construction of highways, bridges, and large-scale buildings. This surge in construction activities has led to an increased demand for heavy machinery and equipment, such as cranes, excavators, and wind turbines, which rely heavily on slewing bearings for their operation. The need for efficient and reliable components in these industries is propelling the market for slewing bearings.

Competitive Landscape

The major players operating in the slewing bearing market include Kaydon Corporation, NTN Corporation, Rotek Inc., SKF (India) Ltd, Jiangsu Liangang Slewing Bearing Co., Ltd., Harmonic Drive LLC, Schaeffler India Limited, The Timken Company, NSK Ltd, ABC Bearings, igus GmbH.

Recent Key Strategies and Developments

- In June 2024, igus GmbH Introduced a groundbreaking slewing ring bearing made from an innovative wood-plastic composite (WPC). This new product, composed of 50% wood and 50% high-performance plastics, represents a major advancement in the use of renewable materials in industrial manufacturing. By offering a cost-effective, lubrication-free solution with a reduced CO2 footprint, igus is setting a new standard for sustainable industrial components.

- In September 2022, The Timken Company announced its agreement to acquire GGB Bearing Technology, a division of Enpro Industries. This acquisition is set to enhance Timken's business by adding GGB's leading metal-polymer bearings to its portfolio, creating strong synergies and expanding its capabilities in friction management. The deal positions Timken to better address customers' most demanding applications with a broader range of solutions and a solid growth outlook.

Industry Trends

- The rise of Industry 4.0 and the growing use of robotics in manufacturing and logistics are increasing the demand for slewing bearings. These bearings are crucial in robotic arms and automated systems, where precision and reliability are paramount.

- The adoption of smart technologies is enabling real-time monitoring of slewing bearings. This helps in predictive maintenance, reducing downtime, and extending the lifespan of the equipment. Sensors and IoT devices are being integrated into slewing bearings to monitor their condition and performance continuously.

Key Sources Referred

- Invest India

- International Renewable Energy Agency (IREA)

- International Energy Agency (IEA)

- India Brand Equity Foundation (IBEF)

- International organization of standardization

Key Benefits For Stakeholders

- This report provides a quantitative analysis of the slewing bearing market share, segments, current trends, estimations, and dynamics of the slewing bearing market analysis from 2024 to 2033 to identify the prevailing slewing bearing market opportunities.

- The market research is offered along with information related to key drivers, restraints, and opportunities.

- Porter's five forces analysis highlights the potency of buyers and suppliers to enable stakeholders make profit-oriented business decisions and strengthen their supplier-buyer network.

- In-depth analysis of the slewing bearing market report segmentation assists to determine the prevailing market opportunities.

- Major countries in each region are mapped according to their revenue contribution to the global market.

- Market player positioning facilitates benchmarking and provides a clear understanding of the present position of the market players.

- The report includes the analysis of the regional as well as global slewing bearing market trends, key players, market segments, application areas, and market growth strategies.

Slewing Bearing Market Report Highlights

| Aspects | Details |

| Market Size By 2033 | USD 7.2 Billion |

| Growth Rate | CAGR of 5.3% |

| Forecast period | 2024 - 2033 |

| Report Pages | 340 |

| By Type |

|

| By Gear Type |

|

| By Application |

|

| By Region |

|

| Key Market Players | Jiangsu Liangang Slewing Bearing Co., Ltd., Harmonic Drive LLC, igus GmbH, ABC Bearings, Rotek Inc, NSK Ltd, Schaeffler India Limited, The Timken Company, SKF (India) Ltd, Kaydon Corporation, NTN Corporation |

Technological innovations in bearing design, Advancements in industrial automation and robotics are the upcoming trends of Slewing Bearing Market in the world.

wind turbine is the leading application of Slewing Bearing Market

Asia-Pacific is the leading application of Slewing Bearing Market

$7.2 billion is the estimated industry size of Slewing Bearing by 2033.

Kaydon Corporation, NTN Corporation, Rotek Inc., SKF (India) Ltd, Jiangsu Liangang Slewing Bearing Co., Ltd., Harmonic Drive LLC, Schaeffler India Limited, The Timken Company, NSK Ltd,ABC Bearings , igus GmbH are the top companies to hold the market share in Slewing Bearing.

Loading Table Of Content...