Slip Ring Market Research, 2032

The Global Slip Ring Market size was valued at $1.3 billion in 2022, and is projected to reach $1.7 billion by 2032, growing at a CAGR of 3.2% from 2023 to 2032.

A slip ring, also known as a rotary electrical joint, is a device used to transmit electrical signals and power between rotating and stationary parts of a system. It consists of a stationary component (stator) and a rotating component (rotor) that are connected through brushes and contact rings. The slip ring is to enable the transfer of electrical signals or power from a stationary part to a rotating part or vice versa while allowing the rotation to continue uninterrupted. It is commonly used in electromechanical systems where continuous rotation is required, such as in electric motors, generators, wind turbines, radar antennas, and rotating cameras.

Market Dynamics

The rising adoption of automation and robotics in various industries necessitates the use of slip rings to enable the transmission of power, data, and signals between stationary and rotating parts of robotic arms, automated assembly lines, and other robotic systems. Slip rings allow for continuous rotation without tangling cables, ensuring seamless communication and reliable operation. Moreover, slip rings find extensive application in packaging machines and material handling equipment, where continuous rotation is required. These machines require slip rings to transmit power and signals to rotating components such as conveyor belts, rotating arms, and packaging tools.

The increasing demand for efficient packaging and material handling solutions drives the need for slip rings in the automation & robotics sector. Furthermore, Computer Numerical Control (CNC) machines are widely used in various industries for precision machining and automated manufacturing processes. Slip rings play a crucial role in CNC machines by enabling the transmission of power and signals to rotating spindles, rotary tables, and other moving parts. As CNC machines become more prevalent, the demand for slip rings in the automation & robotics sector grows.

The renewable energy sector, particularly wind energy, relies on slip rings in wind turbines. Slip rings are essential for transferring power and signals from the rotating blades to the stationary components, such as generators and control systems. With the increasing adoption of wind energy as a clean power source, the demand for slip rings in the automation & robotics sector is expected to rise. These factors are driving the demand for slip ring market forecast in industrial automation applications, and the market is expected to expand further as automation continues to transform industries worldwide.

Slip rings are intricate electromechanical devices that require precise engineering and manufacturing processes. The complexity of their design, which includes multiple conductive rings, brushes, and housing, adds to the manufacturing cost. The specialized equipment and skilled labor required for production contribute to the overall expense. Moreover, slip rings often need to be customized to meet specific application requirements, such as the number of rings, voltage and current ratings, signal types, and housing materials. Customization adds complexity to the manufacturing process and increases costs.

Moreover, the variability in slip ring designs makes it challenging to achieve economies of scale in production, further impacting the cost. Slip rings must maintain reliable electrical connections over an extended period, even in demanding environments. Ensuring high-quality materials, precise manufacturing tolerances, and rigorous testing adds to the cost. Companies that prioritize reliability may be willing to pay the premium, but price-sensitive industries may seek alternative solutions with lower upfront costs.

The market for slip ring industtry has a sizable opportunity due to the advancements in technology. As industries increasingly rely on automation and digitization, there is a growing need for slip rings that can handle high-speed data transmission. Advancements in slip ring technology can enable higher data transmission capabilities, allowing for seamless communication between rotating and stationary components. This presents an opportunity for slip ring manufacturers to cater to industries such as robotics, aerospace, and telecommunications.

Moreover, the renewable energy sector, including wind turbines and solar power plants, requires slip rings for transmitting power and signals from rotating components to stationary parts. With advancements in slip ring technology, manufacturers can develop more efficient and reliable slip rings specifically designed for renewable energy applications. Advancements in slip ring technology have led to the development of more compact and lightweight slip ring designs.

These smaller slip rings are particularly beneficial for industries with limited space or weight constraints, such as medical devices, aerospace, and defense. Manufacturers that can offer compact slip rings with high performance and reliability have a competitive advantage in these markets. These are major factors that are projected to offer opportunities for slip ring market growth players during the forecast period.

The Key Players profiled in this Report Include:

Schleifring GmbH, Michigan Scientific Corporation, Moog Inc., Cobham Plc, Electro-Miniatures Corporation, United Equipment, Accessories, Inc, NSD Corporation, Conductix-Wampfler, STEMMANN-TECHNIK, and Rotac Co. Ltd. Investment and agreement are common strategies followed by major market players. For instance, in December 2019, Moog, Inc. successfully acquired GAT Inc., a German company is engaged in the manufacturing and development of high-end fluid rotating unions and slip rings.

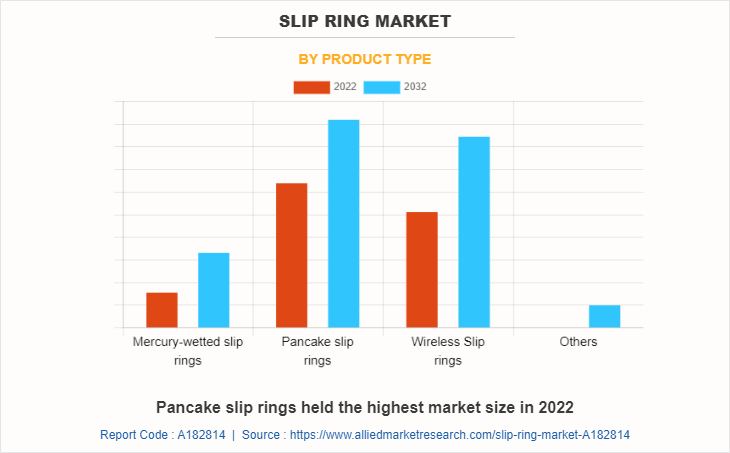

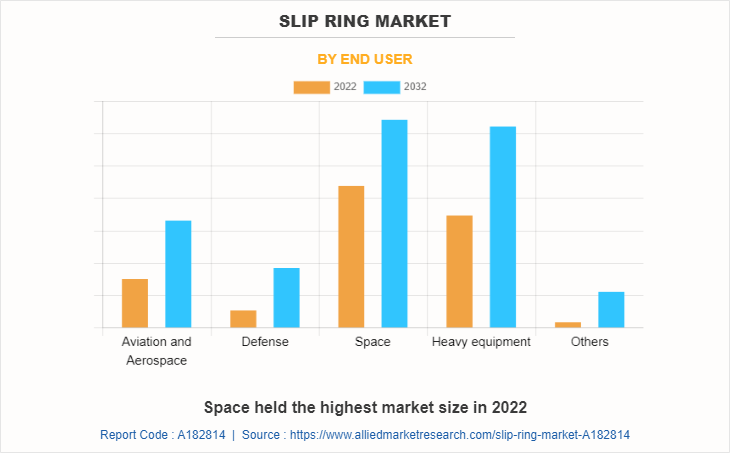

The slip ring market overview is segmented on the basis of product type, end user, and region. By product type, the market is divided into mercury-wetted slip rings, pancake slip rings, wireless slip rings, and others. By end user, the market is classified into aviation & aerospace, defense, space, heavy equipment, and others. By region, the market is analyzed across North America, Europe, Asia-Pacific, and LAMEA.

The slip ring market is segmented into Product Type and End user.

By Product Type:

The pancake slip rings sub-segment dominated the market in 2022. Pancake slip rings are known for their compact and low-profile design, making them ideal for applications with limited space. With the increasing trend of miniaturization in various industries, such as robotics, medical devices, and aerospace, the demand for pancake slip rings has been rising steadily. Moreover, pancake slip rings find applications in wind turbines to transfer power and data signals between the stationary and rotating parts, such as the blades and the nacelle.

The growth of the wind energy sector has contributed to the demand for slip rings, and pancake slip rings have gained popularity due to their space-saving design. Furthermore, pancake slip rings are utilized in various defense and aerospace applications, including radar systems, missile guidance systems, and surveillance equipment. As defense spending continues in many countries and space exploration activities increase, the demand for slip rings is likely to remain strong. Pancake slip rings play a vital role in the smooth movement and rotation of camera equipment used in broadcasting and entertainment industries. As these industries continue to evolve, the demand for slip rings for camera systems is expected to increase. These are predicted to be the major factors affecting the slip ring market size during the forecast period.

By End User:

The space sub-segment dominated the global slip ring market share in 2022. The exploration of space has been a significant driver for the slip ring market. Space agencies and private companies launching exploration missions require reliable slip ring technology to ensure seamless data transmission, power transfer, and communication between rotating and non-rotating components on spacecraft and rovers. Moreover, the increasing demand for satellites for communication, earth observation, weather monitoring, and navigation systems has driven the need for slip rings in satellite components. Slip rings are essential for transmitting power and signals between the rotating and stationary parts of satellites and space equipment. The trend of miniaturization in satellite design has led to the need for compact and lightweight slip ring solutions. As satellites become smaller and more sophisticated, the slip ring market has adapted to provide space-grade miniature slip ring solutions that can meet the specific requirements of small satellites. The commercial space industry has been expanding rapidly, with private companies launching more satellites, space tourism ventures, and other space-related activities. This growth has driven the demand for slip rings in various space applications.

By Region:

North America dominated the global market in 2022 . North America has a significant presence of various industries, including manufacturing, automotive, aerospace, and robotics. The demand for slip rings is driven by the increasing adoption of industrial automation, where slip rings are used to enable continuous rotation and transfer signals and power between stationary and rotating parts in machines and equipment.

Moreover, the defense sector in North America relies on slip rings for various applications, such as radar systems, surveillance equipment, and missile systems. As governments invest in modernizing their defense systems, the demand for advanced slip ring technologies increases. Furthermore, North America is home to a robust medical device industry. Slip rings find applications in medical imaging equipment, such as CT scanners and MRI machines, where they enable the transmission of signals and power between rotating and non-rotating parts.

Key Benefits For Stakeholders

- This report provides a quantitative analysis of the market segments, current trends, estimations, and dynamics of the slip ring market analysis from 2022 to 2032 to identify the prevailing slip ring market opportunities.

- The market research is offered along with information related to key drivers, restraints, and opportunities.

- Porter's five forces analysis highlights the potency of buyers and suppliers to enable stakeholders make profit-oriented business decisions and strengthen their supplier-buyer network.

- In-depth analysis of the slip ring market segmentation assists to determine the prevailing market opportunities.

- Major countries in each region are mapped according to their revenue contribution to the global market.

- Market player positioning facilitates benchmarking and provides a clear understanding of the present position of the market players.

- The report includes the analysis of the regional as well as global slip ring market trends, key players, market segments, application areas, and market growth strategies.

Slip Ring Market Report Highlights

| Aspects | Details |

| Market Size By 2032 | USD 1.7 billion |

| Growth Rate | CAGR of 3.2% |

| Forecast period | 2022 - 2032 |

| Report Pages | 270 |

| By Product Type |

|

| By End user |

|

| By Region |

|

| Key Market Players | Schleifring GmbH, United Equipment Accessories, Inc, Moog Inc., Rotac Co., Michigan Scientific Corporation, conductix-wampfler usa, Mersen S.A., Stemmann-Technik GmbH, NSD Corporation, COBHAM PLC |

The major growth strategies adopted by slip ring market players are investment and agreement.

The increasing global demand for renewable energy, particularly wind power generation, is driving the slip ring market. Slip rings are used in wind turbines to transfer electrical power and signals from the rotating blades to the stationary components, enabling efficient power generation and control, which is estimated to drive the adoption of slip ring.

The growing trend of industrial automation across various sectors, such as manufacturing, packaging, robotics, and aerospace, is a significant driver for the slip ring market growth. Slip rings are essential components in automated machinery and equipment, enabling the transmission of power, signals, and data between stationary and rotating parts, which is estimated to generate excellent opportunities in the slip ring.

The rapid growth of the electric vehicle industry is another significant driver for the slip ring market expansion. Slip rings are used in electric vehicles for functions such as power transmission, charging systems, steering column connections, and motor control. As the adoption of electric vehicles increases, the demand for slip rings is anticipated to increase in the upcoming years.

The pancake slip rings sub-segment of the product type acquired the maximum share of the global slip ring market in 2022.

Asia-Pacific will provide more business opportunities for the global slip ring market in the future.

Schleifring GmbH, Michigan Scientific Corporation, Moog Inc., Cobham Plc, Electro-Miniatures Corporation, United Equipment, Accessories, Inc, NSD Corporation, Conductix-Wampfler, STEMMANN-TECHNIK, and Rotac Co. Ltd. are the major players in the slip ring market.

The report provides an extensive qualitative and quantitative analysis of the current trends and future estimations of the global slip ring market from 2022 to 2032 to determine the prevailing opportunities.

Manufacturing & industrial equipment companies and automotive & transportation industry are the major customers in the global slip ring market.

Loading Table Of Content...

Loading Research Methodology...