Stud Welding Machine Market Research, 2031

The Global Stud Welding Machine Market was valued at $1 billion in 2021, and is projected to reach $1.7 billion by 2031, growing at a CAGR of 5.1% from 2022 to 2031.

Market Introduction and Definition

The stud welding machine is used to affix fasteners or studs on the base of any product or any holes. The machine is used for fixing studs onto the parent material without perforation. It is a widely used welding method that is time-saving and inexpensive. The stud welding machine is used for joining various materials together which helps in creating a long-lasting and strong bond.

The stud welding machine market size is increasing rapidly as attaching metal plates and studs help in forming structural frameworks. The stud welding machine industry is gaining huge popularity across bridges, buildings, and others. These factors are anticipated to boost the stud welding machine market growth in the upcoming years. Stud welding machine offers several advantages over other welding methods. For instance, a stud welding machine is a faster process as welding ¾” fastener takes less than one second to be welded. The stud which is welded using a stud welding machine is single-sided and access to another side of the workpiece is not required. With the stud welding machine, a fully cross-sectional weld is created which indicates that the fill face of the fastener is welded which offers a worry-free and strong weld. The stud welding machine is a portable heating device that acts as powerful welding equipment. These machines are extensively used in the manufacturing industry. These aspects are anticipated to create a positive impact on the stud welding machine market outlook in the coming years.

Some of the limitations associated with the stud welding machine market are anticipated to restrain the market growth. For instance, the stud welding machine can be used for welding relatively small components such as plugs or studs. Also, the stud welding process is hazardous as the structural integrity, molten metal, and heat penetration are more at the start of the welding process.

The growing use of stud welding machines for building power steering, heat shields, instrument panels, dashboard components, lighting systems, electrical wire routing, brake lines, and others is anticipated to propel the stud welding machine market demand during the forecast timeframe.

Furthermore, stud welding machines are used in the construction sector for attaching panels, roof trusses, windows, doors, and stair spindles. In the marine sector, these machines are used for steel decking, securing steel plates, and joining other metal parts. In the aerospace sector, stud welding machines are used for attaching studs to the steel sheet and for the outer structure of missiles. In the cables industry, a stud welding machine is used for attaching wires and cables and removing old cables during the wire-pulling process. It is widely used for manufacturing bearings of bearings, springs, fitting pipes, packaging electronic equipment, mounting furnaces, cooling systems, and for the transport of oil & gas. Such growing applications of stud welding machines are anticipated to drive the market demand in the upcoming years.

Key Players:

STANLEY Engineered Fastening, Midwest Fasteners Inc., Bolte GmbH, KÖSTER & CO. GMBH, ChangZhou Jinda Welding Co., Ltd., HBS Bolzenschweiss-Systeme GmbH & Co. KG, Taylor Studwelding Systems Ltd, HEINZ SOYER BOLZENSCHWEISSTECHNIK GMBH, Cruxweld Industrial Equipments Private Limited, and TFP Corporation.

Market Segmentation

The stud welding machine market is segmented on the basis of type of arc ignition, material, stud diameter, operation, end-use industry, and region.

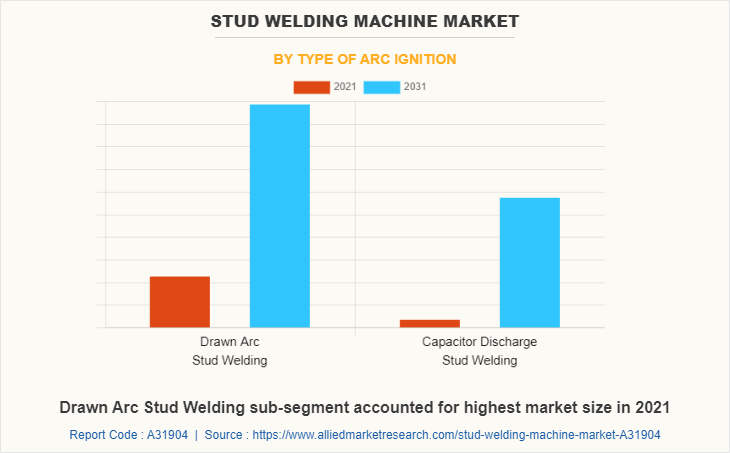

By type of arc ignition, the market is divided into drawn arc stud welding and capacitor discharge stud welding.

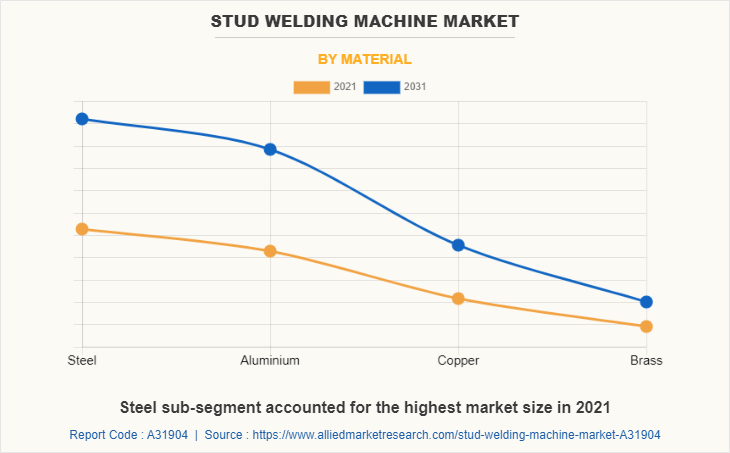

By material, the market is divided into steel, aluminum, copper, and brass.

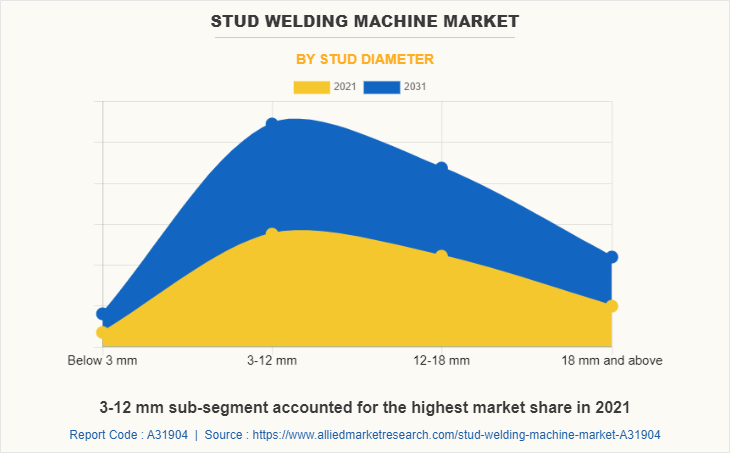

By stud diameter, the market is classified into below 3 mm, 3-12 mm, 12-18 mm, and 18 mm and above.

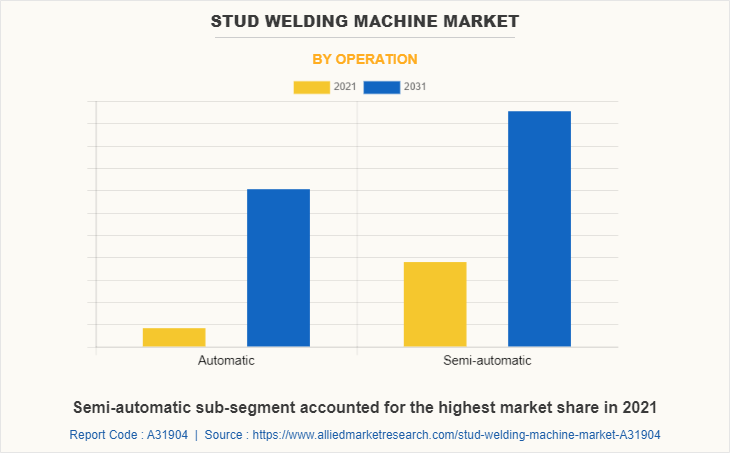

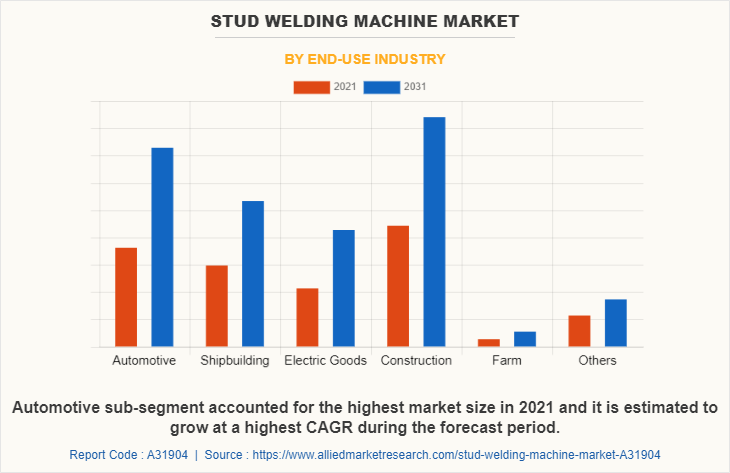

By operation, the market is divided into automatic and semi-automatic. By end-use industry, the market is classified into automotive, shipbuilding, electric goods, construction, farm, and others.

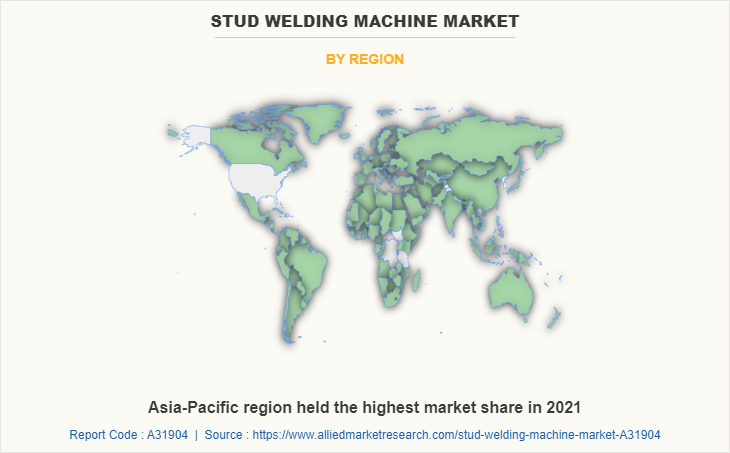

By region, the market is analyzed across North America, Europe, Asia-Pacific, and LAMEA.

The stud welding machine market is segmented into Type of Arc Ignition, Material, Stud Diameter, Operation and End-use Industry.

By Type of Arc Ignition:

The drawn arc stud welding sub-segment dominated the market in 2021 and is projected to grow at the fastest rate during the forecast period. In drawn arc stud welding, the operators use a gun or weld tool against the base metal. Drawn arc stud welding is an efficient method used for attaching fasteners and welding time is 10 to 600 milliseconds. This method uses string penetrative welds with a size of 2mm thickness and above. The stud welding machine offers uniform quality and excellent reliability, eliminates the need for drilling and high duty cycle. These factors are anticipated to boost the drawn arc stud welding sub-segment growth in the upcoming years.

By Material,

The steel segment dominated the global market in 2021 and the aluminum segment is predicted to show the fastest growth during the forecast period. Steel is an excellent material used for the stud welding process as it is easy to work with, strong, and inexpensive. Steel can be used for capacitor discharge stud welding as well as for drawn arc stud welding. Many industries prefer the use of steel for stud welding as it is a sturdy material with excellent properties.

By Stud Diameter:

The 3-12 mm sub-segment dominated the global stud welding machine market in 2021. The growth of this segment is majorly attributed to its growing application across industries such as marine, transportation, shipbuilding, and automotive. The use of 3mm to 12mm studs is known as short cycle stud welding as these studs offer an undisturbed backside finish with a rapid attachment.

By Operation:

The semi-automatic segment dominated the global market in 2021. Semi-automatic stud welding machines are widely used owing to their cost efficiency and ease of operation. This is because, with semi-automatic stud welding, there is no need for skilled labor. With semi-automatic stud welding, no filler wire is required which makes the welding process economical, the overall operation cost is minimized, and ample space for designing is provided. Also, the semi-automatic stud welding machine can be used for high-strength applications.

By End-Use Industry:

The construction sub-segment dominated the global stud welding machine market share in 2021. The stud welding machine is widely used for the construction of bridges. The stud welding machines help organizations in minimizing the downtime of the machinery and ensure that the equipment function properly. The use of stud welding machines in the construction sector ensures versatility and portability as the construction sector demands the use of equipment that can withstand harsh conditions and are suitable for repeated usage. The capacitors and fasteners that are welded using stud welding machines are compatible with any off-highway application. These factors are anticipated to boost the stud welding machine market demand across the construction sector.

By region, Asia-Pacific dominated the global market in 2021 and is anticipated to grow at a significant rate during the forecast period. The growth of this region can be attributed to rapid developments in the construction, automotive, and shipbuilding industries. For instance, China is the leading automotive market in the world in terms of manufacturing, production, and sales. In automotive vehicles, the stud welding machine is used for heat shield components, vehicle exhaust systems, insulation equipment, lighting solutions, power steering parts, and electrical wire frameworks. This is because the use of stud welding machines in the automotive sector offers several benefits. Some of these benefits include user-friendliness, instant welding solutions, strong & long-lasting weld, energy efficiency, cost-effectiveness, clean welding, and invisible welding with no blackening on the other side.

Highlights of the Report

- The report provides an exclusive and comprehensive analysis of the global stud welding machine market trends along with the stud welding machine market forecast

- The report elucidates the stud welding machine market opportunity along with key drivers and restraints of the market. It is a compilation of detailed information, inputs from industry participants and industry experts across the value chain, and quantitative and qualitative assessment by industry analysts.

- Porter’s five forces analysis helps analyze the potential of the buyers & suppliers and the competitive scenario of the market for strategy building

- The report entailing the stud welding machine market analysis maps the qualitative sway of various industry factors on market segments as well as geographies

- The data in this report aims at market dynamics, trends, and developments affecting the stud welding machine market sales

Stud Welding Machine Market Report Highlights

| Aspects | Details |

| Market Size By 2031 | USD 1.7 billion |

| Growth Rate | CAGR of 5.1% |

| Forecast period | 2021 - 2031 |

| Report Pages | 240 |

| By Type of Arc Ignition |

|

| By Material |

|

| By Stud Diameter |

|

| By Operation |

|

| By End-use Industry |

|

| By Region |

|

| Key Market Players | Taylor Studwelding Systems Ltd, KÖSTER & CO. GMBH, Bolte GmbH, HBS Bolzenschweiss-Systeme GmbH & Co. KG, Cruxweld Industrial Equipments Private Limited, STANLEY Engineered Fastening, ChangZhou Jinda Welding Co., Ltd., Midwest Fasteners Inc., TFP Corporation, HEINZ SOYER BOLZENSCHWEISSTECHNIK GMBH |

Analyst Review

The demand for stud welding machine is growing significantly in recent years owing to their wide range of applications across consumer goods, automotive, electronics, and construction sectors. In the heating & ventilation industry, stud welding machines are used for fixing heating elements and burners. It is also used for attaching covers, flanges, and hatches. In the electrical industry, the stud welding machine is used for bonding doors and panels, earthing components, fixing wiring looms, and mounting components on cabinets. In addition, in the mechanical industry, the stud welding machine is used for attaching machinery guards, fixing inspection hatches and cover plates, fixing air and fluid lines, and mounting handles. Such growing applications are anticipated to boost the stud welding machine demand during the forecast timeframe. Compared to other welding processes, the stud welding machine offers faster assembly with fewer welding stages. Some limitations such as stud welding machine can be used for the welding of small components only such as studs or plugs is anticipated to restrict the market growth in the upcoming years. The welding process facilitated by a stud welding machine offers excellent joint stability, endures excellent design versatility, helps in producing one-sided welds, and the end products are attractive and appealing. These aspects are anticipated to provide significant growth opportunities for the stud welding machine market players in the future.

Among the analyzed regions, Asia-Pacific is expected to account for the highest revenue share in the market in 2031, followed by North America, Europe, and LAMEA. Rapid growth in the automotive and construction sectors, where stud welding machines are widely used for vehicle exhaust systems, power steering parts, heat shields, and others is driving the growth of the Asia-Pacific stud welding machine market.

A wide range of applications of stud welding machines in the construction automotive, food processing, shipbuilding, and electrical sectors are the upcoming trends in the stud welding machine market.

The leading applications of stud welding machine include its use across heating ventilation, decorative, and consumer goods sector.

Asia-Pacific is the largest regional market for stud welding machine.

The stud welding machine market is anticipated to reach $1,678.8 million by 2031.

STANLEY Engineered Fastening, Midwest Fasteners Inc., Bolte GmbH, and KÖSTER & CO. GMBH are the major players in the stud welding machine market.

Loading Table Of Content...