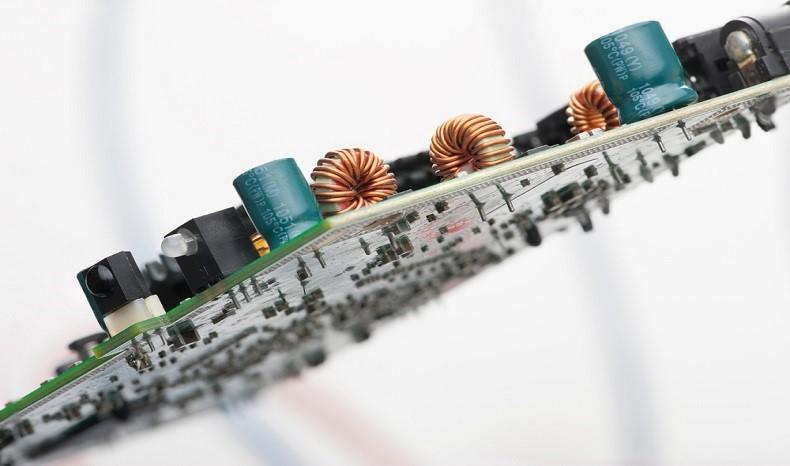

Surface-mount technology (SMT) is a method by which electrical components are mounted directly on the surface of a printed circuit board (PCB). An electronic device made using surface mount technology is called a surface mount device. This technology varies significantly from traditional soldering thru-hole technology. SMT uses relatively different soldering equipment and principles that provide more electrical conductivity and reliability in comparison to thru-hole soldering. SMT is currently the most commonly used method for consumer electronic assemblies, which are low-cost and high-production. Components of surface mount technology consists of passive surface mount devices, transistors & diodes, and integrated circuits. The initial costs are lower for these materials. Their applications provide better mechanical efficiency under conditions of shock and vibration (partly due to lower mass and partly due to less cantilevering).

COVID-19 scenario Analysis:

- Global surface mount technology market has been significantly impacted by the COVID-19 outbreak. New projects throughout the world have stalled, which, in turn, have led to decline in demand for analog semiconductors.

- Global factories have struggled to integrate new surface mount technologies as workers have stayed in their homes, which disrupted the global supply chains.

- The impact of COVID-19 on this market is temporary as just the production and supply chain is stalled. Once the situation improves, production, supply chains, and demand for surface mount technologies are gradually going to increase.

- This COVID-19 lockdown would help companies think about more advanced surface mount technologies to enhance efficiency.

Top impacting factors: Market Scenario Analysis, Trends, Drivers and Impact Analysis

High demand for surface mount technology is expected to rise rapidly, due to growing the electronics industry, increasing the mass production of electronics devices, increasing usage of flexible materials printed circuit boards, and the trend of miniaturization and need for electrical and mechanical components mounting. In addition, the high costs of surface mounting equipment system are expected to restrict the market growth during the forecast period. Surface mount technology is unsuitable for high-power or high-voltage parts such as power circuitry.

The global surface mount technology market trends are as follows:

Consumer electronics segment to have the largest market share

The consumer electronics application segment is expected to hold the largest surface mount technology market share, due to high development which is responsible for the reduced size and weight of consumer electronics devices is the inclusion in these applications of surface mount technology. Surface mounted components are smaller, thinner and lighter than through-hole packages that use more space and power, and contribute significantly to the product's total weight.

Asia-Pacific to account for the largest size, with the highest CAGR during the forecast period

Rise in wireless communication standards and increase in demand for 3G/4 G networks boost demand for SMT in this region's telecommunication sector. China is one of the world's fastest-growing economies and its SMT market is expected to expand, mainly owing to large number of SMT manufacturing companies. The surface mount technology market growth is also driven by rise of electric vehicles in the automotive industry of Asia-Pacific. Companies operating in the market employ many growth strategies such as new product releases and innovations, alliances, partnerships, collaborations and acquisitions to gain a competitive edge and extend their distribution networks.

The surface mount technology market is also expected to rise in the near future, due to the increased demand for LED lighting. The LEDs have become an alternative source of light to traditional fluorescent and incandescent bulbs. LED lighting's lifetime and electrical efficiency is much higher than incandescent lamps, and they're much more effective than fluorescent bulbs. The electronics manufacturing industry is reaping the benefits of LED features such as small size and low power consumption are more cost-effective than conventional lighting sources and results in high-quality LED system by implementation of automated SMT assembly of LED components.

Key benefits of the report:

- This study presents the analytical depiction of the global surface mount technology industry along with the current trends and future estimations to determine the imminent investment pockets.

- The report presents information related to key drivers, restraints, and opportunities along with detailed analysis of the global surface mount technology market share.

- The current market is quantitatively analyzed to highlight the global surface mount technology market growth scenario.

- Porter’s five forces analysis illustrates the potency of buyers & suppliers in the market.

- The report provides a detailed global surface mount technology market analysis based on competitive intensity and how the competition will take shape in coming years.

Questions answered in the surface mount technology market research report:

- Which are the leading market players active in the surface mount technology market?

- What would be the detailed impact of COVID-19 on the market?

- What current trends would influence the market in the next few years?

- What are the driving factors, restraints, and opportunities in the surface mount technology market?

- What are the projections for the future that would help in taking further strategic steps?

Surface Mount Technology Market Report Highlights

| Aspects | Details |

| By Equipment |

|

| By Industry Vertical |

|

| By Components |

|

| By Region |

|

| Key Market Players | ASM Assembly Systems GmbH & Co. KG (Germany), Orbotech Ltd. (Israel), Hitachi High-Technologies Corporation (Japan), Viscom AG (Germany), Mycronic AB (Sweden), Fuji Machine Manufacturing Co., Ltd.(Japan), Juki Corporation (Japan), CyberOptics Corporation (U.S.), Electro Scientific Industries Inc. (Oregon), Nordson Corporation (U.S.) |

Loading Table Of Content...