Synthetic Zeolites Market Research, 2031

The global synthetic zeolites market was valued at $5.3 billion in 2021 and is projected to reach $7.3 billion by 2031, growing at a CAGR of 3.3% from 2022 to 2031.

Report key highlighters

The global synthetic zeolites market has been analyzed in terms of value ($Million) and volume (Kiloton). The analysis in the report is provided on the basis of zeolite type, application, 4 major regions, and more than 15 countries.

The global synthetic zeolites market report includes a detailed study covering underlying factors influencing industry opportunities and trends.

The synthetic zeolites market is fragmented in nature with few players such as BASF SE, Albemarle Corporation, Arkema, and Clariant, which hold a significant share of the market.

The report facilitates strategic planning and industry dynamics to enhance decision-making for existing market players and new entrants entering the synthetic zeolites industry.

Zeolites are microporous, crystalline, and hydrated aluminosilicates formed from the hydrothermal crystallization of aluminosilicate gels. Zeolites are produced using cheaper raw materials than silica and alumina sources, including natural zeolites, municipal solid waste incinerator ash, clay minerals, coal ashes, and industrial slags. Sizes of zeolites are created to be extremely exact, unique, uniform, crisp, and robust, to accommodate the requirements of a variety of clients.

Synthetic zeolites are typically manufactured through the alkali treatment of silica- and alumina-bearing raw materials of synthetic, natural, or waste origin. The first synthetic zeolite, ZK-5 (Na2Al2Si4-6O12-16.6H2O), was created in the late 1940s by Richard Barrer, who studied the conversion of minerals under the influence of strong salt solutions at elevated temperatures (170°C to 250°C). Later, Milton pioneered the use of more reactive starting materials, which enabled milder reaction conditions and led to the discovery of zeolite A, which has become the most important synthetic zeolite, used commercially as a water softener in the detergent industry, in radioactive waste treatment, and in the purification of industrial wastewaters

Increased demand for synthetic zeolite from the detergent industry

The exceptional ion-exchange capabilities of synthetic zeolites make them ideal for use as water softeners for the removal of calcium, magnesium, and other ions. Due to many environmental requirements, zeolite 4A has replaced poly-condensed phosphate builders, such as Sodium Tripolyphosphate (STPP), which was once utilized in the detergent industry. According to China Cleaning Industry Association (CCIA) statistics, the production and growth rate of sodium tripolyphosphate have declined. As the market for phosphorus-containing products declines, 4A zeolite (widely used as a phosphate-free additive) has played an increasingly significant role in the market for additives. 4A zeolite has a powerful exchange action with calcium ions in water, as well as the ability to co-sediment insoluble pollutants and enhance cleaning detergency. The primary reason for this is the growing knowledge of the polluting effects of phosphate-based detergent additives.

Several nations have established regulations prohibiting the use of phosphate builders in the production of detergents, which has led to an increase in the use of zeolites. For instance, the European Parliament and the Council of the European Union, have created legislation prohibiting the use of phosphate builders. The key players from China, India, and Japan, use synthetic zeolites on a big scale since they are far less harmful than STPP. For instance, Tosoh Corporation offers HSZ®-series for synthetic zeolites. HSZ-series zeolites are high silica zeolites with higher SiO2/Al2O3 mol ratios than zeolite molecular sieves. They also have high thermal and acid stability, making them useful for catalyst and adsorbent applications. In addition, these have a homogeneous molecular size, strong adsorption capacity at low adsorbate concentrations, and high sequestration power at elevated temperatures. The detergent industry has increased its use of zeolite-4A for the reasons mentioned, as well as the fact that it is environmentally friendly.

The demand for agricultural and soil remediation has increased. Since synthetic zeolites can hold onto nutrients in the soil and release them gradually over time, they are mostly utilized in fertilizers. Due to their high porosity, synthetic zeolites are able to store greater quantities of water. Therefore, synthetic zeolites are able to sustain soil moisture levels by hydrating and rehydrating, preventing soil drying during drought and water shortage. Synthetic zeolites are favored over natural zeolites because, with the aid of chemical characteristics and pore diameters, they may be created and will exhibit superior hydrothermal stability. In the construction business, they are mostly employed as additives in the mixing of asphalt concrete, since they help to reduce the temperature during asphalt production and installation. This reduces the usage of fossil fuels and the emission of carbon dioxide and aerosols.

In place of cooling gases, contemporary refrigeration systems use synthetic zeolites and water. Because they contain a mineral that may absorb water vapor while generating heat, synthetic zeolites are utilized. The new system is both ecologically and economically viable. Zeolite granulates are non-toxic, naturally occurring, and non-combustible; therefore, they are environmentally friendly. The usage of CO2 is eliminated because there is no use of refrigeration gases. The cooling system is energy-efficient since it uses less electricity. Due to the natural rather than mechanical nature of zeolites, their long-life cycles result in cheap maintenance costs. This is driving the synthetic zeolites market during the forecast period.

Synthetic zeolites are utilized in numerous sectors. However, the availability of substitutes may restrict market expansion. The demand for the product as adsorbents is anticipated to be driven by the increase in water purification and wastewater treatment operations. As an alternative to molecular sieve catalysts, the existence of chemical components such as metals, enzymes, and others may hamper the industry's growth. In addition, a rise in gasoline prices may increase transportation costs, which is projected to act as a market restraint. Despite the availability of numerous development drivers, the global market for synthetic zeolite is confronted by a number of formidable obstacles. Synthetic zeolite production costs are one of the most main challenges facing this sector. Another challenge is the logistical restrictions that increase shipment expenses.

"In the near future, expanding the use of synthetic zeolites in the hydrogen economy is expected to lead to lucrative opportunities. The increase in demand for hydrogen-based energy as a clean and sustainable energy source is driving the demand for synthetic zeolites. In the creation of hydrogen, zeolites are utilized as a catalyst. However, hydrogen energy generation is in its infancy, with attractive opportunities in the coming years."

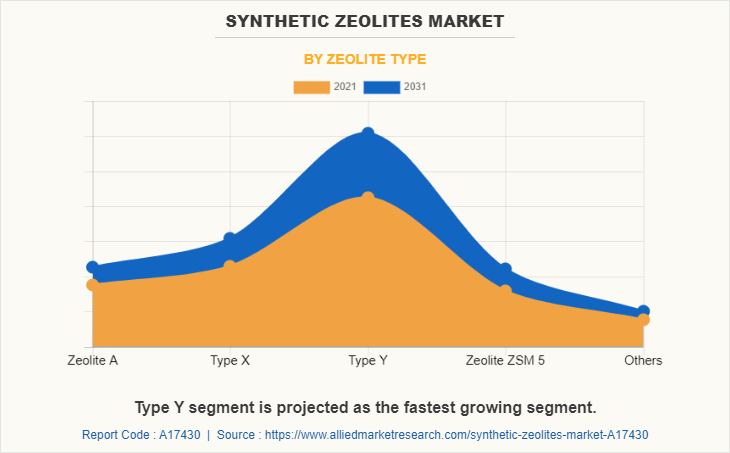

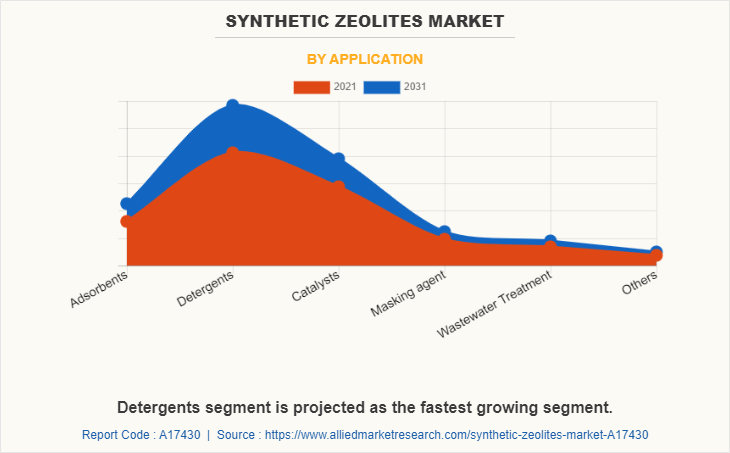

The synthetic zeolite market is segmented into zeolite type, application, and region. On the basis of zeolite type, the market is divided into zeolite A, type X, type Y, zeolite ZSM-5, and others. On the basis of application, it is categorized into adsorbents, detergents, catalysts, masking agents, wastewater treatment, and others. Region-wise, the market is studied across North America, Europe, Asia-Pacific, and LAMEA.

The type Y segment accounted for the largest share i.e., 40.0%. This is because zeolite Y is a zeolite with a high silica concentration. This type of zeolite possesses exceptional catalytic and adsorption properties that are essential to the petroleum refining process and the aerosols manufacturing industry. Zeolite Y is an extremely porous, crystalline chemical compound with alternating SiO and AlO tetrahedra in its structure.

The detergents segment accounted for the largest share i.e., 38.8%. This is due to its water-softening properties. Synthetic zeolites are able to efficiently extract Calcium+2 and Magnesium+2 ions from water and release Sodium + ions into the water. In addition, synthetic‐¯zeolites are an eco-friendly alternative to Sodium Tri-Polyphosphate (STPP), an environmental danger. In the next years, the detergent industry's emphasis on eco-friendly products is anticipated to increase demand for zeolite and contribute to the expansion of the global zeolite market.

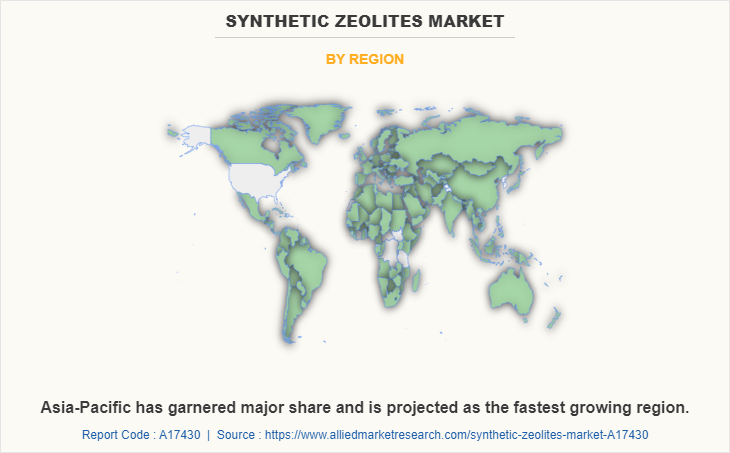

Region-wise, Asia-Pacific is projected to register robust growth during the forecast period and accounted for the largest share i.e., 43.8% because of the increase in demand for phosphate-free detergents in Asia-Pacific. This is due to rapid urbanization, population growth, and lifestyle changes. The Asia-Pacific region ranked second in the globe in terms of refinery capacity. This has increased the demand in the region for FCC and hydrocracking catalysts. The increasing demand for synthetic zeolites in the Asia-Pacific region is a result of the expanding detergent and catalyst industries.

Key potential factors that drive the synthetic zeolites market demand:

The expansion of the detergents sector, particularly in emerging countries based on expanding industrialization, is projected to lead the synthetic zeolites market to rise rapidly globally in this forecast period. There are several types of zeolites, including A, AX, Y, P, and X. In the detergents sector, their usefulness is widespread and widely acknowledged.

In the refining and petrochemical industries, zeolites have been widely used as catalysts, which is another factor driving market expansion. During the projected period, the growth of the global synthetic zeolites market is anticipated to be fueled by the expansion of the petrochemicals sector in the Asia-Pacific region as a result of the increasing demand and recognition for chemicals among end-use industries.

The global market participants are acknowledging the requirement for products that adhere to environmental rules and are investing in their research and development departments accordingly. The product demand for adsorbent applications as a segment of the market is anticipated to develop at a high rate as a result of rising environmental emissions, particularly from the transportation sector.

Consumers are more likely to purchase a luxury vehicle as a result of the automobile industry's rapid expansion and their rising purchasing power. The automotive industry is one of the largest adsorbent consumers. In addition, robust growth in the industrial sector and global population increase are anticipated to drive the market growth of synthetic zeolites over the forecast period.

The industry for specialty zeolites is gaining traction. For this reason, manufacturers are making substantial investments to expand the production capacity of specialty zeolites. For example, in September of 2017, BASF invested in a new facility in Ludwigshafen, Germany, in order to increase its production capacity of specialized zeolites. These specialized zeolites are utilized to manufacture cutting-edge emissions catalysts for heavy-duty and light-duty diesel cars.

During the forecast period, the market for synthetic zeolite is anticipated to expand at a significant rate due to the increasing demand for synthetic zeolite products across various end-use industries, such as detergent manufacturing industries, as a result of rising hygiene awareness among consumers globally.

The major players operating in the global synthetic zeolites market are BASF SE, Albemarle Corporation, Arkema, Clariant, CWK Chemiewerk Bad Köstritz GmbH, Honeywell International Inc., KNT Group, Tosoh Corporation, W. R. Grace & Co.-Conn., Zeolyst International. Other players operating in the market are Huiying Chemical Industry (Quanzhou) Co., Ltd, National Aluminum Company Limited (NALCO), PQ Corporation, and SHOWA DENKO K.K.

Latest development strategies undertaken by key players

- On July 2nd, 2021, BASF expanded its chemical catalyst recycling capacity and capability with the acquisition of Zodiac Enterprises LLC in Caldwell, Texas. Additional personnel will be hired to expand the site’s production capabilities. It may lead to the growth of synthetic zeolite products.

- On June 14th, 2021, Honeywell announced that It partnered with the Defense Research Development Organization (DRDO) and the Council of Scientific and Industrial Research–Indian Institute of Petroleum (CSIR–IIP), Government of India, to supply molecular sieve adsorbents (zeolites) to accelerate setting up of Medical Oxygen Plants (MOP) in the country to address the ongoing pandemic.

- On June 18th, 2019, W. R. Grace & Co.-Conn acquired Rive Technology, Inc. along with its Molecular Highway zeolite technology. The acquisition helped to make use of Rive’s technology to develop different types of zeolites for chemical catalysts and processes.

Key Benefits For Stakeholders

- This report provides a quantitative analysis of the market segments, current trends, estimations, and dynamics of the synthetic zeolites market analysis from 2021 to 2031 to identify the prevailing synthetic zeolites market opportunities.

- The market research is offered along with information related to key drivers, restraints, and opportunities.

- Porter's five forces analysis highlights the potency of buyers and suppliers to enable stakeholders make profit-oriented business decisions and strengthen their supplier-buyer network.

- In-depth analysis of the synthetic zeolites market segmentation assists to determine the prevailing market opportunities.

- Major countries in each region are mapped according to their revenue contribution to the global market.

- Market player positioning facilitates benchmarking and provides a clear understanding of the present position of the market players.

- The report includes an analysis of the regional as well as global synthetic zeolites market trends, key players, market segments, application areas, and market growth strategies.

Synthetic Zeolites Market Report Highlights

| Aspects | Details |

| Market Size By 2031 | USD 7.3 billion |

| Growth Rate | CAGR of 3.3% |

| Forecast period | 2021 - 2031 |

| Report Pages | 300 |

| By Application |

|

| By Zeolite type |

|

| By Region |

|

| Key Market Players | Honeywell International Inc., Arkema, W. R. Grace & Co.-Conn., tosoh corporation, BASF SE, Albemarle Corporation, zeolyst international, CWK Chemiewerk Bad Köstritz GmbH, Clariant, KNT Group |

Analyst Review

According to the insights of the CXOs of leading companies, the majority of demand for synthetic zeolite is produced by laundry detergents due to its ionizing activities and water-softening properties. In addition, zeolites have a variety of benefits over other building materials in the manufacture of detergents. For instance, zeolites have exceptionally high product stability regardless of the method applied (granulation, spray drying, extrusion, and many others.). Therefore, increase in use of synthetic zeolite in the detergent industry is projected to propel market expansion. In addition, rise in demand for adsorbents from the automotive, agriculture, aerospace, building materials, aviation, water filtration and chemicals industries is predicted to create attractive growth prospects. However, the hazardous properties of synthetic zeolite, as well as the production and shipping costs, are significant factors that may hinder the expansion of the market.

The synthetic zeolites market attained $5.3 billion in 2021 and is projected to reach $7.3 billion by 2031, growing at a CAGR of 3.3% from 2022 to 2031 is the estimated industry size of Synthetic Zeolites.

Increased demand for synthetic zeolites from the detergent industry is the main driver of the Synthetic Zeolites Market.

Detergents are the leading application of the Synthetic Zeolites Market.

Zeolite type Y is expected to drive the adoption of Synthetic Zeolites.

BASF SE, Albemarle Corporation, Arkema, Clariant, CWK Chemiewerk Bad Köstritz GmbH, Honeywell International Inc., KNT Group, Tosoh Corporation, W. R. Grace & Co.-Conn., Zeolyst International are the top companies to hold the market share in Synthetic Zeolites.

Asia-pacific is the largest regional market for Synthetic Zeolites.

Consumers are more likely to purchase a luxury vehicle as a result of the automobile industry's rapid expansion and rising purchasing power. The automotive industry is one of the largest adsorbent consumers. In addition, robust growth in the industrial sector and global population increase are anticipated to drive the market growth of synthetic zeolites over the forecast period. these are the upcoming trends of the Synthetic Zeolites Market in the world.

Loading Table Of Content...