Welding Equipment Market Research: 2031

The Global Welding Equipment Market Size was valued at $8.3 billion in 2021, and is projected to reach $13.9 billion by 2031, growing at a CAGR of 5.1% from 2022 to 2031. Welding is a type of fabrication process in which two or more metal components are fused together by using heat, pressure, or both. Welding equipment are powerful tools that use electricity to fuse two or more metal components.

The welding equipment industry includes equipment related to the processes of welding, which is the joining of materials, particularly metal materials using fusion. This process entails the efficient heating and pressing of the base metals in such a way that they melt and then cool while forming a closely fitted solid structure. Welding equipment also consists of tools and accessories like welding machine, electrodes and filler metals or electrodes wires and safety gear that is needed for the several welding processes used in industries like automobile, construction, manufacturing and aerospace.

Also, the end user of welding equipment market which includes various industries such as automotive, aerospace, shipbuilding, and oil & gas industries due to the need to repair and maintain products and equipment. An increase in the demand for lightweight materials, high-grade alloys, and complicated structures in these industries necessitates the development of effective methodologies in welding.

Current trends in the welding equipment market indicate that it is expanding owing to several factors such as increased manufacturing in developing world and increase in demand for metal for manufacturing. The need for welding equipment is mainly driven by the development of various industrial sectors and infrastructure developments around the globe for fabrication and construction as well as for maintaining the structures creating a demand for products. Increasing populations in developing countries such as those in Asia and Africa have seen an increasing demand for welded structures and components owing to rising industrialization.

In addition, there are various hindrances in the market as well. Some of them include the fact that there are fluctuating metal prices across many regions of the world. Despite challenges like a shortage of qualified employees and harsh competition, market participants try to overcome these difficulties in various ways. These strategies include investing in innovation, partnerships, and investing in improving customer service and entering new markets. It is stated that leading manufacturers put their efforts and money in research and development in order to introduce innovative welding equipment with increase in features, performance and usability. Some examples include the creation of sophisticated welding machines, the manufacture of welding wires and fluxes that meet the demands of changing customer groups and the needs of the industrial line, and the production of various welding accessories.

Arc welding and resistance welding are the two most commonly used types of welding. Arc welding Arc welding is a fusion welding method in which AC or DC power is used to create an intense heat of around 6500°F, which melts the metal between the workpieces thereby creating a joint. Arc welding can be further classified into consumable and non-consumable methods. Consumable welding methods include gas metal arc welding (GMAW), shielded metal arc welding (SMAW), flux cored arc welding (FCAW), submerged arc welding (SAW), electro-slag welding (ESW), and arc stud welding (SW).

Furthermore, non-consumable methods primarily include Tungsten Inert Gas Welding (TIG), and Plasma Arc Welding (PAW). Thus, the availability of wide range of welding equipment makes it suitable for various applications in automotive, construction, and heavy engineering, and small workshops.

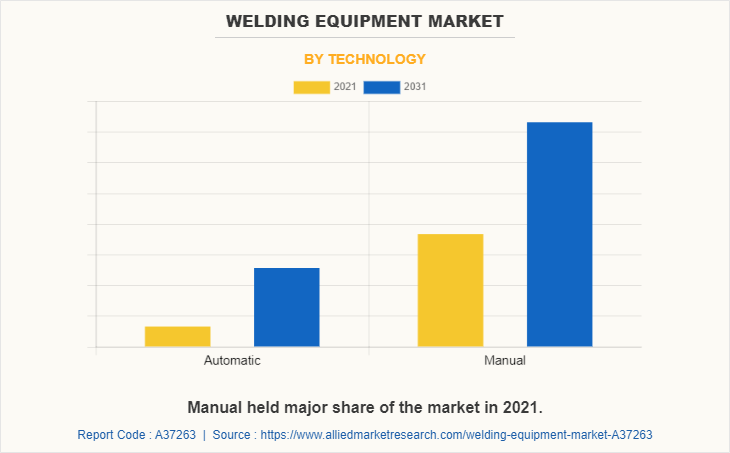

In addition, welding can be done manually or automatically with the help of robots. Manual welding offers various advantages such as greater flexibility and cost efficiency. For instance, in workshops, the strength of welders can be increased or decreased depending on the number of on-going welding projects, thereby increasing the cost efficiency of the workshops. Furthermore, automatic welding can be further classified into automated welding processes and semi-automatic welding processes.

In semi-automatic, an operator manually loads the metal workpieces in and removes it once the workpieces are fused together, and in a fully automatic process, machines move the workpieces to be welded from start to end. Automatic welding is extensively used for high precision welding operations in automotive, and aerospace industry. Thus, the flexibility of welding equipment to perform various environments further drives the welding equipment market growth.

Moreover, the easy availability of manual welding machines, increases its use in small workshops and construction sites. Furthermore, automatic welding equipment can be programmed as per the required design of the end product. These factors further boost the sales of welding equipment in developed and developing economies.

Furthermore, the automobile sector is witnessing significant growth in emerging economies. For instance, the Indian automotive industry has grown by about 10% from about $100 billion in 2021 to about $110 billion in 2022. The noticeable growth is due to the development of roads, rise in standard of living, and increase in middle class population in developing regions, thus, further driving the adoption of welding equipment which are used to manufacture a wide range of automotive components.

Moreover, the rising purchasing power of masses in emerging economies has also fueled the building construction industry, thereby boosting the welding equipment market. Furthermore, the global aerospace industry has grown by about 15% since 2021 till 2022. The aerospace industry relies highly on welding equipment for delivering tight tolerance parts. Automatic welding equipment in the aerospace industry help in the manufacture of a variety of complex components. Thus, growth in the aerospace industry drives the market for welding equipment industry.

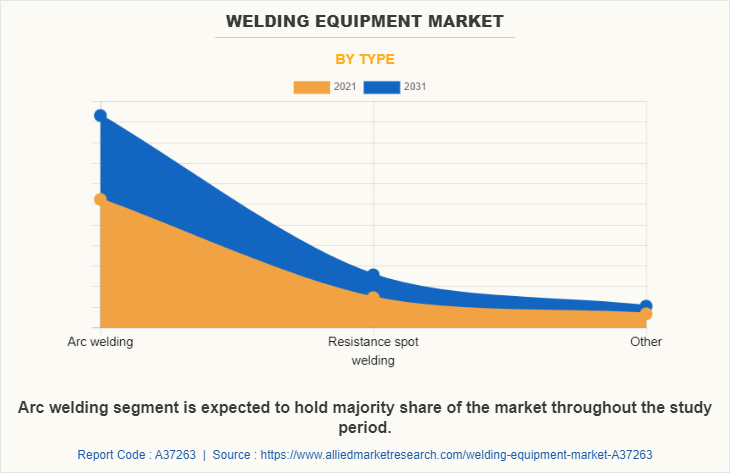

By Type:

The welding equipment market is categorized into arc welding, resistance welding and other. In 2021, the arc welding segment accounted for the highest market share in the global welding equipment market share, and the resistance spot welding segment is anticipated to grow at a fastest CAGR during the forecast period.

The global construction industry is growing at a steady rate since the past few years. For instance, according to the World Bank, in order to adequately meet the infrastructure needs of the fast-growing urban population in India, India would need to invest $840 billion, or $55 billion annually, in urban infrastructure during the next 15 years.

Furthermore, the World Bank report also estimates that by 2036, 600 million people, or 40% of the population, will reside in urban areas throughout India. As a result, the building construction industry will witness rapid growth. Welding equipment are extensively used in construction industry for various applications such as joining steel reinforcements, fabricating external window grills, fabricating metal doors and building steel structures. Thus, as the construction industry continues to grow, the demand for welding equipment is expected to increase, leading to further growth in the welding equipment market.

By Technology:

The welding equipment market is categorized into manual and automatic. In 2021, the manual segment accounted for the highest market share in the global welding equipment market share, and the automatic segment is anticipated to grow at the fastest CAGR during the forecast period.

In addition, the primary advantages of welding is that it creates strong and durable joints between metal parts that can withstand high stresses and loads. This makes it an ideal process for constructing structures, vehicles, and machinery that require high strength and reliability. In addition to that Welding can be used to join a wide range of metals, including steel, aluminum, and copper. It can also be used to join different thicknesses of metal, making it a versatile process.

Furthermore, welding can be a very efficient process when compared to other methods of joining metals. It can be done quickly and easily, which makes it ideal for mass production of metal products. Such highly desirable advantages of the welding are anticipated to drive the market growth during the forecast period.

However, the global economic slowdown constraint the growth of the market. Industrial economies in North America, Europe, and Asia are witnessing slow economic growth while the manufacturing growth of a number of emerging industrial economies is also decreasing. Uncertainty caused by Russia Ukraine conflict has affected the growth prospects of many of the European economies. Among other emerging industrial economies, China’s growth slowdown and there has been a serious manufacturing downturn in Latin America. This uncertainty in the global manufacturing sector can hamper the growth of the welding equipment market.

The novel coronavirus has rapidly spread across various countries and regions, causing an enormous impact on the lives of people and the overall community. It began as a human health condition and later became a significant threat to global trade, economy, and finance. The COVID-19 pandemic had halted the production of many components of welding equipment due to lockdown. The economic slowdown initially resulted in reduced spending on automotives sales and government spending on public transportation projects.

However, owing to introduction of various vaccines, the severity of COVID-19 pandemic has significantly reduced. As of end of 2022, the number of COVID-19 cases have diminished significantly. This has led to the full-fledged reopening of welding equipment manufacturing companies at their full-scale capacities. Furthermore, it has been more than two years since the outbreak of this pandemic, and many companies have already shown notable signs of recovery.

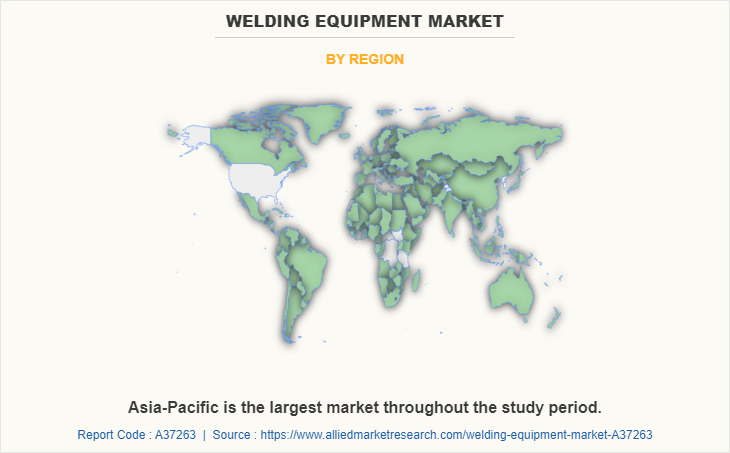

The welding equipment market is analyzed across North America, Europe, Asia-Pacific, and LAMEA. In 2021, Asia-Pacific had the highest welding equipment market share and is anticipated to secure the leading position during the forecast period, due to large construction and automotive industry.

The welding equipment market is segmented into Type, Technology and End user industry. By type the market is categorized into arc welding, resistance welding and other. On the basis of operation, it is bifurcated into manual and automatic. As per end-user industry, the market is categorized into automotive, construction, heavy engineering, and Other.

Region Wise:

The market is analyzed across North America, Europe, Asia-Pacific, and LAMEA. Asia-Pacific dominated the market in 2021, accounting for the largest welding equipment market share. LAMEA is anticipated to grow with the highest CAGR throughout the forecast period. This is attributed to high growth rate of disposable income of the region and a significantly large untapped market.

Competition Analysis

The major players profiled in the welding equipment market forecast report include Coherent, Inc., Fanuc, Illinois Tool Works Inc., Panasonic Industry Co., Ltd., The Lincoln Electric Company, ESAB, ACRO Automation Systems, Inc., Kemppi Oy, Carl Cloos Schweisstechnik GmbH, and Cruxweld Industrial Equipments Pvt. Ltd.

Some examples of product launches in the market

In October 2022, Kemppi launched its new the X5 FastMig Pulse welding system, which was created exclusively for industrial use. The modular welding solution is made to be applied in a variety of settings, allowing the manufacturers to develop the assembly that best meets their requirements.

In October 2022, Coherent Corp launched its new HIGHvision, a machine vision system for laser welding heads that greatly improves the efficiency of electric vehicle (EV) batteries and motors.

Key Benefits For Stakeholders

- This report provides a quantitative analysis of the market segments, current trends, estimations, and dynamics of the welding equipment market analysis from 2021 to 2031 to identify the prevailing welding equipment market opportunity.

- The market research is offered along with information related to key drivers, restraints, and opportunities.

- Porter's five forces analysis highlights the potency of buyers and suppliers to enable stakeholders make profit-oriented business decisions and strengthen their supplier-buyer network.

- In-depth analysis of the welding equipment market segmentation assists to determine the prevailing market opportunities.

- Major countries in each region are mapped according to their revenue contribution to the global market.

- Market player positioning facilitates benchmarking and provides a clear understanding of the present position of the market players.

- The report includes the analysis of the regional as well as global welding equipment market trends, key players, market segments, application areas, and market growth strategies.

Welding Equipment Market Report Highlights

| Aspects | Details |

| Market Size By 2031 | USD 13.9 billion |

| Growth Rate | CAGR of 5.1% |

| Forecast period | 2021 - 2031 |

| Report Pages | 180 |

| By Type |

|

| By Technology |

|

| By End user industry |

|

| By Region |

|

| Key Market Players | kemppi Oy, Panasonic Industry Co., Ltd., Cruxweld Industrial Equipments Pvt. Ltd., Illinois Tool Works Inc., The Lincoln Electric Company, ACRO Automation Systems, Inc., Fanuc, ESAB, Carl Cloos Schweisstechnik GmbH, Coherent, Inc. |

Analyst Review

The welding equipment market has witnessed significant growth in the past few years owing to surge in automotive and infrastructure development activities. The rise in demand for cost effective and precise welding solutions in countries such as the U.S., Canada, the UK, Germany, and China has fueled the growth of the welding equipment market.

Furthermore, growth in infrastructure projects is positively influencing the market growth especially in developing countries such as India, China, and Vietnam. Moreover, integration of latest advanced technologies provides lucrative opportunities for the growth of the market.

Growth of automotive and construction industry are some of the major trends Welding Equipment Market in the world.

Welding equipment is extensively used in automotive, construction, and heavy engineering.

Asia-Pacific is the largest regional market for Welding Equipment.

$8,303.4 Million is the estimated industry size of Welding Equipment in 2021.

Coherent, Inc., Fanuc, Illinois Tool Works Inc., Panasonic Industry Co., Ltd., The Lincoln Electric Company, ESAB, ACRO Automation Systems, Inc., and Kemppi Oy are some of the top companies to hold the market share in Welding Equipment.

The Welding Equipment market is projected to reach $13,888.1 million by 2031.

The company profile has been selected on factors such as geographical presence, market dominance (in terms of revenue and volume sales), various strategies and recent developments.

Latest version of global Welding Equipment market report can be obtained on demand from the website.

Loading Table Of Content...

Loading Research Methodology...