Table Of Contents

Yerukola Eswara Prasad

Pooja Parvatkar

Gasification Potential in the Carbon Dioxide (CO2) Industry

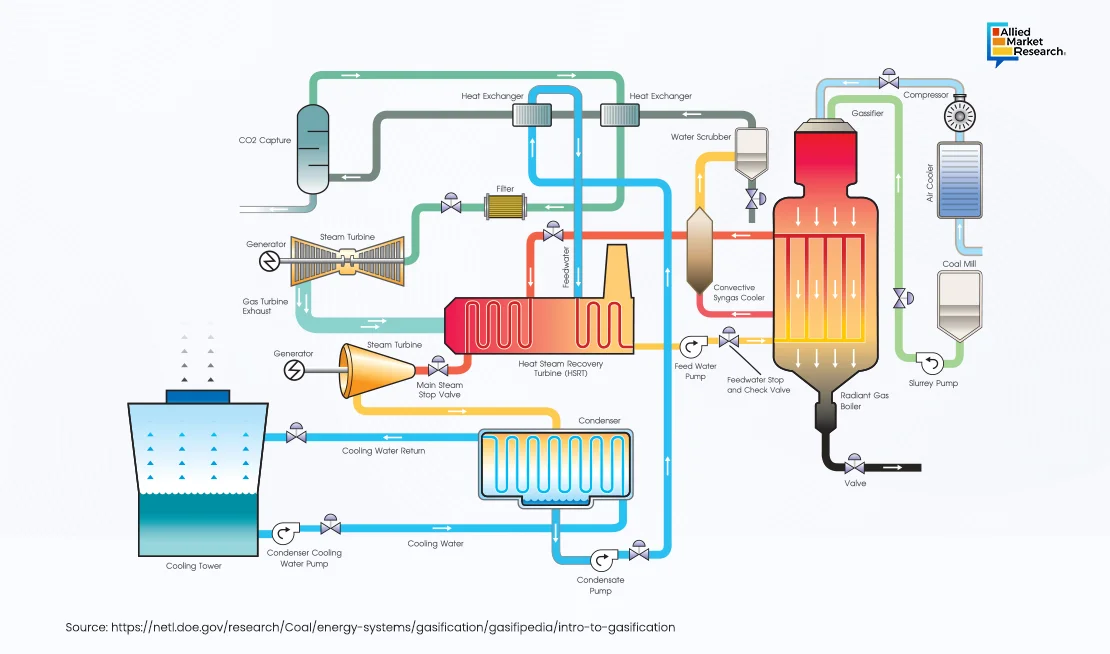

Gasification is a process that converts organic or fossil fuel-based carbonaceous materials into carbon monoxide, hydrogen, and carbon dioxide. This is achieved by reaction of the materials at high temperatures with a controlled amount of oxygen and/or steam. The resulting gas mixture, often called syngas or producer gas, is used as a fuel for various applications, including electricity generation, chemical production, and heating. According to a study by Allied Market Research (A.M.R.), the global gasification market is expected to register a CAGR of more than 5% between 2023 and 2032.The gasification process can be visualized as below:

Feedstock and Processing

The choice of feedstock, which is employed in the process of gasification, depends on factors such as availability, cost, environmental considerations, the desired end-use of the syngas, specific goals of the gasification project, considering economic, environmental & technical factors and more. Here are some common types of gasification feedstocks:

- Coal: Coal is a traditional and widely used feedstock for gasification. It can be used to produce syngas for electricity generation, chemical production, and other industrial applications.

- Biomass: Biomass feedstocks include organic materials such as wood, crop residues, agricultural wastes, and dedicated energy crops. Biomass gasification is often considered a renewable and environmentally friendly option. Carbon-neutral sourced biomass when used sustainably contributes to energy solutions.

- Municipal Solid Waste (MSW): Gasification of municipal solid waste involves converting household and commercial waste into syngas. This process helps reduce landfill usage and can provide an energy source from waste materials.

- Natural Gas: Although natural gas is already a gaseous fuel, gasification of natural gas are employed in processes including steam methane reforming to produce syngas, which is used in various chemical and industrial applications. It provides flexibility in feedstock sources and can be integrated into existing natural gas infrastructure.

- Petroleum Residues: Heavy residues from petroleum refining processes are gasified to produce syngas, which is an alternative to traditional refining processes. It can utilize refinery by-products and provides flexibility in the use of hydrocarbon feedstocks.

- Waste Plastics: Gasification of waste plastics involves converting plastic materials into syngas. This can be an environmentally beneficial method for managing plastic waste.

- Industrial Wastes: Various industrial by-products and wastes, such as rubber, textiles, or paper residues, are used as feedstocks for gasification.

- Renewable Feedstocks: Renewable feedstocks, such as algae or organic residues from bioenergy crops are used for gasification to produce renewable syngas.

With growing environmental concerns, the demand for sustainable waste disposal along with utilization of by-products is growing rapidly. Carbon dioxide (CO2) is one of the major gas by-products formed during the gasification process. This CO2 is either stored or utilized, depending on the feasibility of the project. To observe the growth in the gasification industry, we need to observe and analyze certain parameters that provide insights into the demand perspective.

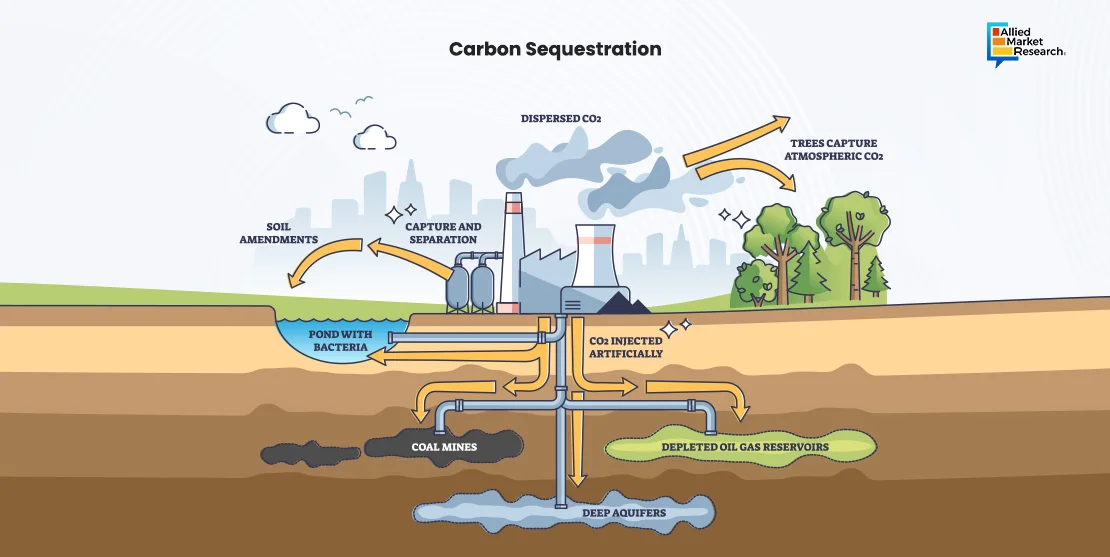

Carbon Dioxide (CO2) Sequestration

Demand for carbon capture, utilization, and storage (CCS) has witnessed tremendous growth driven by rise in penetration in end-use industries such as oil & gas, power generation, iron & steel, chemical & petrochemical, cement, and others. All industry players are investing heavily to find new commercial avenues for their product segments via investment, contracts, and partnerships. The U.S., the UK, Norway, China, and other countries act as the top investment pockets of the carbon capture, utilization, and storage industry. In the UK and Norway, companies are mainly focusing on R&D for improvising EOR processes. Technological developments along with the introduction of several modern technologies that utilize the CO2 released in the production stage are projected to have immense growth prospects in the next ten years. In addition, significant technological advancements in non-power sectors such as petroleum refining, chemical, cement manufacturing, and metal foundry in Norway and the UK have witnessed the implementation of CCS technologies in small or pilot phases. Such favorable initiatives coupled with rise in awareness among policymakers across various industrial sectors regarding the benefits of such techniques to curtail CO2 emissions provide immense opportunities for future investments. For instance, Sleipner and Snøhvit are two major projects in Norway that compress and pipe CO2 and reinject it underground. Around 1.8 million tons per year of CO2 are pressed underground, accumulating a total of 22 million tons in storage currently.

Carbon capture, utilization, and storage (CCUS) helps the oil and gas industry reduce greenhouse gas emissions from the atmosphere. In 2019, more than 24 million tons of CO2 were captured, stored, and utilized, mainly by the oil & gas industry. The majority of CO2 was extracted from natural gas processing plants. According to IEA, natural gas generation will grow at a rate of approximately 2.7% per year between 2012 and 2040, which will account for nearly 30% of the total worldwide energy generation by 2040. The deployment of CCUS in this sector is expected to pave the way for a greener environment and boost CCUS efforts.

Carbon Dioxide Utilization

Carbon dioxide is used in a variety of industrial processes, such as refrigeration, as a solvent in the production of chemicals such as urea & methanol, and as a cleaning agent in the electronics industry. CO2 is also used in medical procedures such as laparoscopy, where it is used to inflate the abdomen to create space for the surgeon to operate. It is also used in respiratory therapy to help patients breathe more easily. Widespread applications of CO2 in various industries such as agriculture, metal fabrication, food and beverages, food & beverage, oil & gas, medical, firefighting, and others are some of the major factors attributed to the growth of the CO2 industry. According to a study by A.M.R., the CO2 market is projected to grow by more than 5% between 2023 and 2032.

Carbon dioxide is used as a feedstock for the production of chemicals, such as methanol and urea. These are being developed by companies such as Carbon Clean Solutions, which has operations in India and China. In 2022, an Australian cement manufacturer, Boral partnered with an Adelaide-based company, Southern Oil Refining, to produce a lower-carbon cement using CO2 captured from the refining process, which involves capturing CO2 emissions from industrial processes and storing them underground in geological formations. CO2 is a natural pesticide that helps to control a wide range of pests and diseases in plants. As per the University of Arizona, carbon dioxide prevents the spread of diseases in the greenhouse at a concentration of 1,000 parts per million.CO2 is able to kill up to 95% of spider mites within 24 hours. Japan’s Mitsui & Co conducts exploration activities for CO2 storage sites in Asia-Pacific region, where it plans to store 15 million tons of CO2 per year for other Japanese businesses.

Market Outlook and Future Scope

In conclusion, gasification is a versatile and sustainable technology with a wide range of applications that address energy needs, waste management, and environmental concerns. The ability to convert diverse feedstocks, including coal, biomass, municipal solid waste, and renewable resources, into valuable syngas makes gasification a promising solution for the current and future energy landscape. However, challenges persist, including the need for effective gas cleanup processes to address impurities in the syngas and ensuring the economic viability of large-scale gasification projects. Ongoing research and development efforts are focused on improving efficiency, lowering costs, and expanding the range of applicable feedstocks.

Allied Market Research delves into the intricacies of Superalloys and other related products, as we aim to provide vendors with comprehensive insights into the evolving landscape. We provide in-depth details through highly curated reports that portray technological advancements, market trends, and government initiatives concerning the domain, which in turn help businesses integrate superalloys into their operations. For further insights, get in touch with AMR analysts.?