Table Of Contents

- From Primitive to Premium: Peering into the Progress of Packaging Products

- Function-filled Packaging Products

- Embracing the 5 Rs—Reuse, Refurbish, Repair, Recycle, Reduce

- Focusing on Consumer Preferences

- Harnessing the Potential of Biodegradables through Eco-friendly Packaging

- Packaging Automation for Product Standardization

- Innovations in Flexible Packaging

- Packaging 2.0: Designing Tomorrow

Yerukola Eswara Prasad

Akshata Tiwarkhede

Packaging Products: Leading People to an Innovative Sustainable Future

Packaging products are advanced engineered products made from metals, plastics, glass, and paper, which are used in interior as well as in exterior applications. They are majorly applicable in protecting, preserving, and transporting a wide range of goods, from electronics and pharmaceuticals to food and beverages. Packaging products play a vital role in facilitating safe and efficient transportation of the goods, resulting in their prolonged shelf life.

From Primitive to Premium: Peering into the Progress of Packaging Products

Packaging products were used from times immemorial, with first instances recorded from Egyptian Civilization. Advancements in production and material science in packaging started during the industrial revolution era, i.e., the eighteenth and nineteenth centuries, wherein paper-based packaging materials were introduced. In addition, tin cans for use in the food & beverage industry were patented in this period. In the twentieth century, the advent of plastic packaging products such as cellophane, polyethylene, polystyrene, and other polymers revolutionized the packaging industry, as they are lightweight, durable, and flexible, making them suitable for protecting goods during transport and reducing shipping costs. Moreover, they provide superior barrier properties to preserve the freshness and extend the shelf life of perishable items. However, with growing concerns of sustainability, the concept of circular economy was propounded, which primarily focuses on reusing, refurbishing, repairing, recycling, and reducing the existing products and materials as long as possible. This, in turn, led to the introduction of bio-based and recyclable products. This implies that packaging has evolved from simple, natural materials to complex, engineered solutions, reflecting advances in technology and the alarming need to address growing environmental awareness.

Function-filled Packaging Products

Packaging acts as a potential marketing tool to attract a large customer base to pick the product off the shelf. With a focus on innovation, modern packaging solutions are designed to be function-filled, offering a plethora of features to meet diverse needs.

For instance, various functions of packaging include protection, product identification, convenience, product promotion, quality & quantity estimation, and facilitating use of products. The basic purpose of packaging products is protection, exhibiting electrical insulation, thermal insulation, fireproofing, moisture & vapor protection, shock & vibration damping, and UV & weather resistance. Other types of packaging create a protection barrier from oxygen, moisture, and dust to retain the freshness and efficacy of food products. The type of product being packaged and the environmental conditions from which the product must be protected determine the material and type of packaging to be employed. Another key role packaging plays is product identification, for instance, a packet of Maggi can be easily identified from a distance. Packaging products not only play a pivotal role in protection and identification but also facilitate convenient transportation of fragile products. In addition, to grab the attention of a large customer base, manufacturers have focused on selling their goods in attractive packages. Moreover, consumers can easily determine the quality of the product without using it depending on the type of packaging. Similarly, with the size of the packet, it is easy to recognize the quantity of the product. Innovative packaging solutions are further gaining ground; for instance, products as hand wash, body lotion, and sanitizer are packaged in pump bottles for convenient use.

As consumer preferences shift toward convenience, packaging companies are continually striving to create solutions that not only excel in functionality but also align with the changing consumer demands. Thus, packaging has evolved into a multifaceted tool for businesses, acting as a silent salesman.

Embracing the 5 Rs—Reuse, Refurbish, Repair, Recycle, Reduce

The production, transportation, and disposal of packaging materials, especially those made from non-renewable resources such as plastics, involve significant energy consumption and the release of greenhouse gases, thus impacting the environment and contributing to carbon emissions. However, the use of sustainable packaging materials, such as recycled or bio-based packaging products, and more efficient production processes can help reduce these emissions. Implementation of stringent environmental regulations and inclination of consumers to achieve the social goal of sustainable living have significantly fostered the demand for bio-based packaging products. The growing preference for packages made from biodegradable and compostable materials such as bioplastics, plant-based materials, compostable films, and recycled materials, including recycled paper and cardboard, will help to achieve net-zero emissions.

Furthermore, QR codes and RFID tags are being integrated to enhance the sustainability of packaging by improving supply chain transparency and enabling better tracking and recycling processes. In addition, implementing closed-loop recycling systems where packaging materials are continuously recycled and reused within the industry serves as a remarkable initiative to promote sustainable practices.

Moreover, brands are offering take-back programs for their packaging, encouraging consumers to return used packaging for recycling or reuse. Thus, sustainability practices taken by giants significantly influence industry standards, drive innovation in environment-friendly technologies, and set an example for smaller companies to adopt more sustainable practices.

For instance, ProAmpac, a global leader in flexible packaging and material science, has been nominated as the finalist at the 2024 Environmental Packaging Awards. The Environmental Packaging Awards ceremony will be held at The Park Plaza Victoria, London on June 26, 2024. ProAmpac’s ProActive Recyclable RP-1000—kerbside-recyclable fiber-based packaging solution—has received recognition in the Fresh Fruit and Vegetables category for collaborating with Marks and Spencer’s Select Farms Organic potato range. Lynsey Maddison, director of product development at ProAmpac, said “Our collaboration with Marks and Spencer on this sustainable packaging solution underscores our commitment to providing environmentally responsible options that meet the evolving needs of consumers and retailers.”

Focusing on Consumer Preferences

Consumers are likely to choose products with sustainable packaging, influencing brands to adopt greener practices. Clear labeling of packaging materials and their environmental impact helps consumers make informed choices. Labels such as "biodegradable," "compostable," and "made from recycled materials" are becoming prevalent. Agricultural residues, such as bagasse (sugarcane waste) and wheat straw, are being used as raw materials for packaging. Thus, it is essential to reuse, refurbish, repair, recycle, and reduce to embrace a sustainable future.

Consumers are demanding sustainable packaging solutions, which use biodegradable resources that can be recycled after use. According to a study by EcoFocus on behalf of Evergreen Packaging, packaging made of biodegradable materials is extremely influential to 72% of shoppers’ purchase decisions in the U.S. Moreover, half of the shoppers usually look for beverages that are packaged using renewable materials. For the same reason, resin-based flexible packaging has gained momentum in recent years.

Harnessing the Potential of Biodegradables through Eco-friendly Packaging

Unlike conventional plastics, which can persist in the environment for hundreds of years, biodegradable packages decompose into non-toxic byproducts like water, carbon dioxide, and biomass within a shorter timeframe, reducing environmental pollution and waste. Growing consumer awareness regarding the damaging environmental effects of single-use plastics is increasing the demand for bio-based products in the packaging industry. Substitute products such as polylactic acid, cellulose, polyhydroxyalkanoates, starch, palm leaves, hemp, and bagasse are making their in-roads in the packaging industry. For instance, Oceanium (UK), a seaweed-based manufacturer, produces seaweed-based packaging solution, which is an all-natural, home-compostable bio-packaging that replaces traditional use-and-throw packaging. In addition, Lam’on (Bulgaria), a packaging manufacturer, manufactures 100% compostable and biodegradable lamination film and foil packaging solutions. These packaging foil products are developed from polylactic acid derived from corn. This foil also contains silver nanoparticles as an anti-bacterial and oxygen barrier agent, thus making it suitable for food applications.

Furthermore, the adoption of lightweight packaging has increased among manufacturers and corresponding end users, as it enables lighter, more productive renditions of a specific package, wherein the final product is a better version of the original product. Moreover, food firms and packaging partners are witnessing constant pressure from end-use industries to reduce packaging weights and gauges. Thus, reduction in packaging mass remains a major trend, especially within consumer-driven food packaging markets.

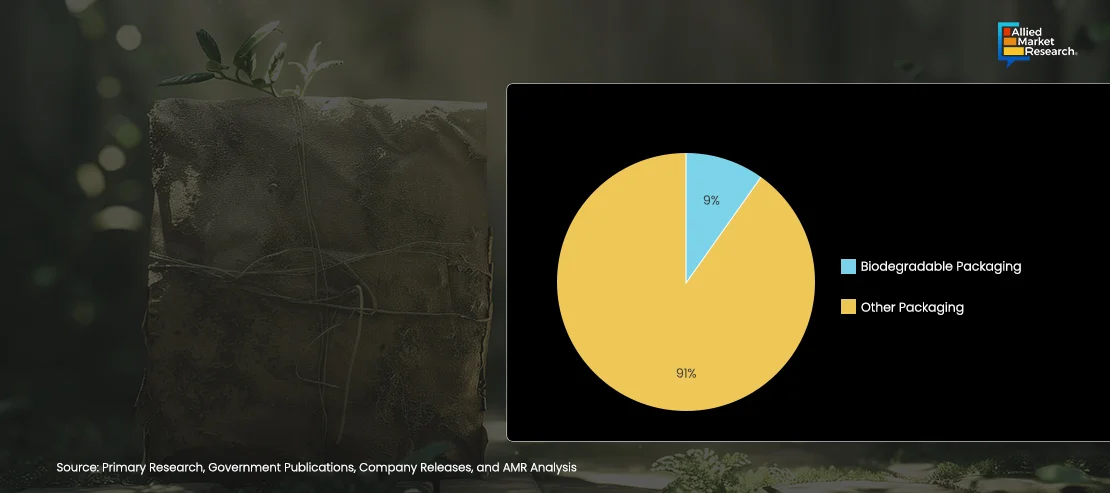

As seen in the above figure, the incorporation of biodegradable products in the packaging industry was in its nascent stage, at just 9%, in 2023. However, different manufacturers globally are actively involved in R&D to launch new biodegradable packaging products. For instance, global packaging solutions provider, Sealed Air launched Cryovac, a compostable overwrap tray made from biomass (derived from renewable wood cellulose) and food-contact grade resin. This approach by the company aims to replace expanded polystyrene-based packaging products mainly used to package fresh poultry and red meat for consumer purchase. Also, in May 2024, SSA Group launched a compostable packaging solution for candy. Such approaches by packaging manufacturers are bound to increase the incorporation of biodegradable packaging products considerably in the coming years.

Packaging Automation for Product Standardization

Packaging manufacturers are focusing toward increasingly sophisticated human-free technology for producing innovative and cost-effective solutions. Challenges such as productivity, accuracy, and quality control are addressed efficiently, thus increasing efficiency, standardization, and precision. Also, AI adoption is growing rapidly, which includes sensors and corresponding systems to capture and analyze images of packaged products throughout the assembly line for final quality assessment. For instance, Wootzano (UK) provides robotic systems to handle extremely delicate objects. This system facilitates functions such as trimming, picking, and packing fresh produce such as fruits & vegetables. Also, LiDAR is introduced for inspection automation and weight estimation of packed products.

Innovations in Flexible Packaging

Innovation in terms of design, functionality, and sustainability is key to the future growth of the flexible packaging industry. Liquid packages made of renewable resources are gaining high traction in the recent years. Consumers preferring buying products that are sustainable and packed in recyclable as well as reusable containers. Thus, reduction in carbon footprint, cost, weight, and design flexibility are some of the major areas of focus among manufacturers. For instance, in 2019, cosmetic products manufacturer, L'Oréal developed its first carton-based cosmetic tube in technical collaboration with Albéa—a cosmetic packaging wholesaler. The carton is made from bio-based paper-like material that replaces majority of the plastic. L'Oréal launched a new cosmetic tube in the second half of 2020. Similarly, Finish-based packaging solutions provider, Stora Enso Oyj developed a paperboard tube for cosmetics packaging as a climate-friendly alternative to plastic tubes. The paperboard tube is suitable for the primary packaging of skin cream products.

Packaging 2.0: Designing Tomorrow

Biodegradable packaging is poised to change the packaging industry in different application sectors by increasing efficiency and affordability. Industry leaders and researchers must collaborate to overcome existing challenges such as cost, scalability, and regulatory hurdles. By prioritizing bioplastics and biodegradable flexible packaging solutions, a more sustainable, efficient, and resilient landscape can be created, benefiting both the environment and the economy.

For further insights, get in touch with AMR analysts.