Table Of Contents

Yerukola Eswara Prasad

Akshata Tiwarkhede

Technical Textile: Transforming Industries with Futuristic Fabric Solutions

Technical textiles are fabrics manufactured primarily for their functional performance rather than their aesthetic appeal. These textiles are engineered to provide enhanced performance over traditional textiles, exhibiting higher tenacity, superior insulation, improved thermal resistance, prolonged durability, and resistance to environmental factors. Thus, these attributes of technical textile make it suitable for use in military & defense, automotive, manufacturing, construction, sports & leisure, agriculture, and pharmaceutical industries.

Generations of Textiles: From Natural to Novel

From 1775 to 1850, first-generation textile fibers, including cotton, wool, silk, flax, and jute were procured directly from nature. The second generation involves the man-made fibers such as nylon and polyester. Along with these synthetic fibers, naturally extracted fabrics continue to play a critical role in the modern textile industry. To meet the needs of the exponentially growing population, evolved the third generation of fabrics, which are made from under-utilized natural resources such as pseudostem of banana plants, leaves of the pineapple, stem of the ramie plant, lotus, and hemp. With the introduction of flexible, extremely lightweight materials and 3D modeling, the twentieth century marked the epitome of smart fabrics. Furthermore, rapid digitization and advancements in technology led to the advent of temperature sensing fabrics, self-cleaning fabrics, and chameleonic fabrics, which are gaining prominence commercially in the twenty-first century.

Adidas Governing the Globe

Adidas is emphasizing on novel ways to incorporate technology to develop state-of-art sports apparel to stand out from the rest. Apart from Adidas’ extensive reach in the sportswear industry, it is also involved in developing technical textiles for athletes such as Climalite, Clima 365, and Climaproof, which aid in maintaining normal body temperature of 37°C, irrespective of the weather conditions. This is achieved by adopting the principle of body mapping that allows designers to place the right fabric in the right place, which helps athletes to stay dry and comfortable, thereby enhancing their performance in all weather conditions.

Biomimicry Burgeoning the Demand for Technical Textile

The phenomenon of biomimicry is currently being used to develop technical textiles. It involves the use of high-level functional mechanisms of living systems to design advanced fabrics. For instance, manufacturers are fabricating textiles that mimic how lotus leaf behaves with water droplets. When water comes in contact with the surface of the leaf, it creates a boundary with the air trapped. Moreover, the surface texture of the leaf contributes to water repellence. To achieve water repellence, it is necessary that the rolling angle should be less than 10 degree. This idea is recreated to design water-repellent fabrics, which can be used to reduce efforts in sports such as swimming.

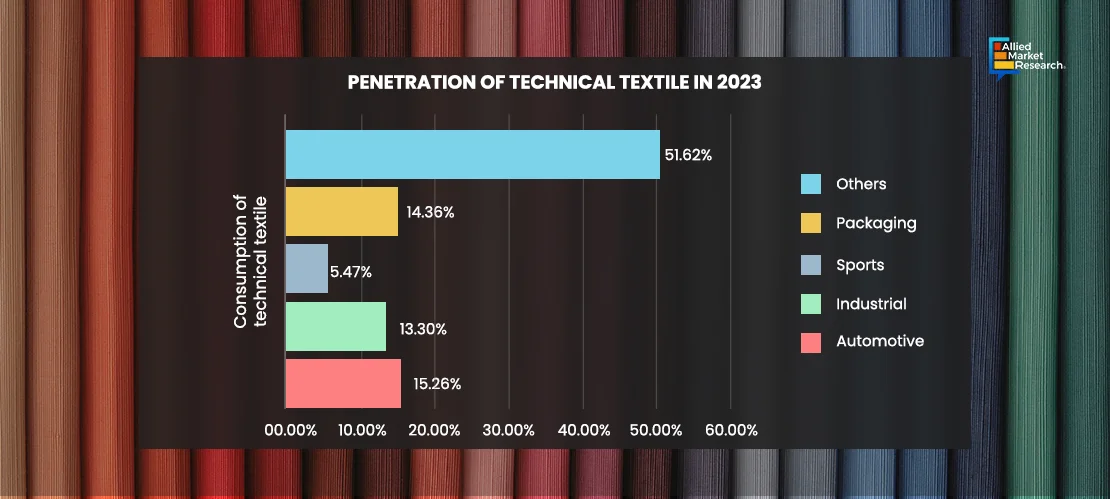

Technical textiles are used in various industrial applications based on their own set of specifications and characteristics.

- Automotive Sector: The highest penetration of technical textiles is observed in the automative industry, which reached up to 15.26% in 2023, and is estimated to witness higher adoption in the coming years. This is majorly attributed to the fact that these textiles are used in car interiors for upholstery, airbags, carpets, and seatbelts, as they exhibit prolonged durability, comfort, and safety features such as flame retardancy. For instance, in April 2024, Lectra launched Versalis Automotive Digital Marking, a digital marking solution for leather materials for use in the automotive industry. These solutions can be used to produce seat covers, acoustic panels, and other textile-based products.

- Packaging Sector: In the packaging sector, the use of woven polypropylene (PP) fabric is gaining high traction for bulk bags, commonly known as flexible intermediate bulk containers (FIBCs). These bags are designed to safely transport and store a wide range of materials, from grains and chemicals to pharmaceuticals and construction materials. The woven PP fabric provides exceptional strength, tear resistance, and UV protection, ensuring the integrity of the content during handling and storage.

- Industrial Sector: In the industrial sector, a prime example is the application of aramid fibers in conveyor belts. Aramid fibers, known for their high strength-to-weight ratio and heat resistance, are incorporated into conveyor belts used in manufacturing facilities and distribution centers. These belts withstand heavy loads, high temperatures, and abrasive materials, facilitating the smooth and efficient movement of goods throughout the production process.

- Sports & Outdoor Gear: Technical textiles are used in sportswear, outdoor gear, and equipment such as tents, backpacks, sport shoes, and performance apparel. They provide moisture management, breathability, flexibility, and resistance to weather conditions.

- Others: Others comprise geotextile, medical, aerospace, and many sectors that are adopting technical textile on a large scale.

- Geotextiles: Geotextiles are used in civil engineering applications such as road construction, erosion control, and drainage systems, as they offer reinforcement, filtration, and separation functions. Nonwoven polypropylene geotextiles are commonly used for separation purposes in road construction. For example, a needle-punched nonwoven geotextile with high tensile strength and puncture resistance can be placed between the subgrade soil and aggregate base to prevent mixing and maintain the structural integrity of the road.

- Medical Sector: Technical textiles possess properties such as biocompatibility, breathability, and antimicrobial properties, which make them suitable in medical products, including surgical gowns, wound dressings, implants, and drug delivery systems. For example, the healthcare sector is adopting the combination of textiles and drugs to meet consumer requirement of minimally invasive surgical procedures. Drugs can be administered effectively with the help of technical textiles by controlled release over a constant period of time and by delivering high concentration of drugs to the targeted tissues. Ortho Evra transdermal contraceptive skin patch—approved by the U.S. Food and Drug Administration—releases hormones through skin that prevent pregnancy.

- Aerospace Sector: Technical textiles are used in aircraft interiors, composites, insulation, and structural components, as they are lightweight as well as exhibit high strength and heat-resistant properties. For instance, carbon fiber textiles are widely used in aerospace for manufacturing composite materials, such as carbon fiber-reinforced polymer, which is exceptionally lightweight and strong. These composites are utilized in structural components like wings, fuselage sections, and empennage, where high strength-to-weight ratio is essential for improving fuel efficiency and performance.

Thus, technical textiles play a crucial role in shaping the future of these industries that they significantly enhance safety, durability, and performance.

MobilTech Crafting the Future of Automotive Industry

“MobilTech” highlights the revolutionary role of technical textiles in driving change within the automotive sector. Automotive textiles are used in various interior applications such as seat covers, carpets, side panels acoustics, filters, belt hoses, and airbags. On an average, 30kg technical textiles were used per car in 2023, almost 50% more as compared to 20kg used in 2000. With an increasing focus on fire protection and safety, the demand for technical textiles in the automotive industry is bound to increase considerably. For instance, seatbelts and airbags have become mandatory in most of the passenger automobiles for increasing the safety of the passengers. Also, for increasing fire resistance and protection, automotive OEMs use technical textiles in seat covers, dashboards, side panels, interior roofing, and boot space.

Technological innovations in technical textiles have constantly been undertaken to offer better materials for use in automotive applications. For instance, BIG Yarn (Belgium), a major yarn manufacturer, in January 2024 launched virgin polyethylene terephthalate (PET) BCF yarns for use in automotive carpets. This is a recyclable material that offers abrasion & stain resistance, along with prolonged durability. In addition, Autoneum, a leader in acoustic and thermal management solutions for vehicles, in November 2022, launched a fully recyclable PET carpet system. This approach by the company has helped automotive OEMs to achieve sustainable end-of-life recycling of electric vehicles.

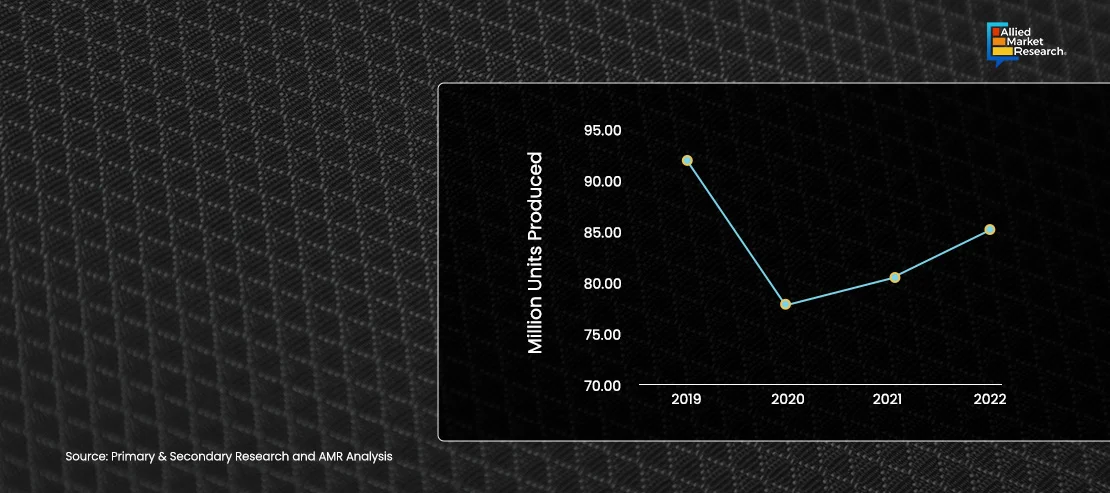

Asia-Pacific has emerged as a hub for automotive production as manufacturers such as BMW AG (Germany) and Volkswagen Group (Germany) have already set up manufacturing units in this region. Due to the outbreak of COVID-19, automotive sales in 2020 witnessed a degrowth of 17%, reaching a sales volume of 77.65 million units as compared to 92.12 million units in 2019. However, post-COVID recovery has been a priority in this sector. One of the key strategies it has employed is normalization, which involves bringing operations back to pre-pandemic levels or adjusting them to fit the new circumstances. Thus, the automotive sales reached around 85 million units in 2022, with highest sales recorded in Asia-Pacific. The factors such as low production costs, availability of economic labor, lenient emission & safety norms, and government initiatives for foreign direct investments have led to significant investment in Asia-Pacific. For instance, Mega Integrated Textile Regions and Apparel in India are expected to attract ?70,000 crore investment in 4 years’ time period, which also provides performance linked incentives schemes. With increasing production and sales of automobiles and high incorporation of technical textile in automobile application, the demand for it is anticipated to increase considerably in the coming years.

Paving the Road to a Sustainable Future

Technical textile serves as an ideal solution to address the challenges of climate change and environmental sustainability. The use of sustainable materials such as biodegradable polymers and recycled fibers while manufacturing will contribute toward reducing carbon footprint. Furthermore, the demand for energy-harvesting fabrics is increasing significantly to support renewable energy initiatives. Thus, the use of sustainable technical textiles is poised to revolutionize the automotive industry by offering innovative solutions that prioritize environmental consciousness without compromising on performance or safety. For instance, Tesla has introduced vegan leather seats made from sustainable materials such as recycled polyester and polyurethane that reduce the reliance on traditional leather production, which is associated with environmental concerns such as deforestation and greenhouse gas emissions. Moreover, the incorporation of sustainable technical textiles in vehicle interiors can enhance comfort, durability, and aesthetics while significantly reducing the carbon footprint of automotive manufacturing processes. By embracing these eco-friendly solutions, the automotive industry can not only meet the growing consumer demand for sustainable transportation options but also contribute to a cleaner and greener future.

Furthermore, in April 2023, Autoneum acquired Borgers Automotive. With this acquisition, Autoneum will operate more than 67 facilities globally and will further expand its presence in sustainable acoustic and thermal management of vehicles. This is particularly useful with Autoneum’s wheel arch liner and trunk lining product lines as well as the truck business. Such an approach will help Autoneum increase its expertise in sustainable product development for automotive OEMs globally.

The integration of eco-friendly technical textiles marks a significant milestone in achieving environmental sustainability in the automotive industry. Thus, their increasing adoption holds the potential to reshape the automotive industry, creating a more sustainable and eco-conscious future for transportation.

The Verdict

Technical textiles are poised to revolutionize the future of industries. From enhancing safety and performance in automotive and aerospace sectors to enabling advanced medical treatments and improving sustainability in construction and fashion, technical textiles are reshaping industries by providing lightweight, durable, and high-performance materials. Their potential to integrate smart technologies, enhance functionality, and reduce environmental impact ensures that they will continue to drive innovation and transformation, shaping a more efficient, sustainable, and interconnected future for industries on a global scale.

For further insights, get in touch with AMR analysts.