Table Of Contents

- The adoption of modular and prefabricated construction creating promising growth opportunities

- The rise of automation and robotic technology opening new possibilities in the sector

- The rapid incorporation of 3D printing technology reshaping the sector’s growth

- Growing use of sustainable & green building materials boosting the dynamics of the industry

- The essence

Sonia Mutreja

Koyel Ghosh

Construction and Manufacturing Domain in Q1 2025: Technological Innovations and Sustainability Trends

The construction and manufacturing sector has been rapidly expanding due to the increasing adoption of modern technologies and growing emphasis on sustainability concerns. Advanced technologies, such as AI, have helped the domain to streamline various processes, increase safety, reduce repetitive tasks, and maintain project schedules. Many leading organizations have increasingly invested in AI-based tools to make informed decisions and utilize data generated by digital technologies. Furthermore, several firms in this field are focusing on green building practices by increasing the use of eco-friendly materials and energy-efficient technologies. These notable trends and innovations have significantly influenced the growth of the industry in the last few years. This newsletter attempts to cover all such major trends that have opened avenues in the construction and manufacturing sector in Q1 2025.

The adoption of modular and prefabricated construction creating promising growth opportunities

In the last few years, increasing demand for prefabrication and modular construction across industries has boosted the growth of the CONMA sector. These types of construction gained huge popularity due to their speed, cost-effectiveness, and sustainability. This approach involves manufacturing building components in a factory and assembling them on-site, which reduces construction time by 30% to 60% compared to traditional methods. Off-site fabrication minimizes weather-related challenges in day-to-day operations, making it ideal for building extension projects by minimizing any delays.

Modular construction offers significant environmental benefits by reducing waste and utilizing recyclable materials like steel. The controlled factory environment ensures high-quality construction with durable, fire-resistant materials. This method also addresses skilled labor shortages by allowing workers to remain in fixed locations with safer conditions, potentially reducing labor costs by up to 25%. The flexibility of modular buildings allows for customization to meet specific needs for offices, classrooms, or residential spaces. Modular extensions are simple to attach, making it a cost-effective solution for future growth. On the other hand, governments and developers across various nations are also promoting this trend to address labor shortages and meet green building standards. Furthermore, the advancements in AI-driven design tools are expected to boost the growth of the prefabricated construction market in Q1 2025.

The rise of automation and robotic technology opening new possibilities in the sector

The integration of automation and robotics is revolutionizing manufacturing by enhancing productivity, reducing costs, and improving safety. Industrial and collaborative robots (cobots), along with AI-driven systems, perform intricate tasks such as welding, assembly, and material handling with greater precision and consistency. This transition enables "lights-out manufacturing" in smart factories, where machines operate with minimal human intervention. These features are expected to boost the growth of the collaborative robots market in the first quarter of 2025.

Robotic automation offers several key benefits, including reduced labor costs and material waste. Robots operate 24/7 without breaks, significantly increasing productivity and operational throughput. Their versatility allows for quick reprogramming to adapt to changing processes or products, providing greater production flexibility. Moreover, automating manufacturing processes removes workers from dangerous jobs, creating a safer work environment. The precision of robots improves product quality and consistency, reducing the chances of manufacturing defects and maintaining consistency. This reliability also enables manufacturers to invest in robots and boosts factory uptime. Moreover, the rise of 5G and edge computing is further enabling real-time data transfer and decision-making in automated manufacturing systems, making industries adopt fully digitized production lines.

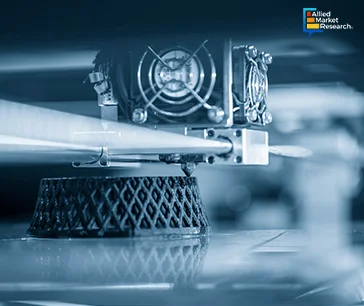

The rapid incorporation of 3D printing technology reshaping the sector’s growth

3D printing, also known as additive manufacturing, is revolutionizing construction and manufacturing by enabling rapid prototyping, on-demand production, and complicated design capabilities. In construction, 3D-printed homes and infrastructure components are developed using concrete-based printing techniques, reducing material waste and labor costs. Many industry leaders are focusing on overcoming the limitations of this technology by simplifying its installation process and minimizing costs through enhanced collaboration. Such initiatives are expected to fuel the growth of the 3D construction printing market in 2025.

Furthermore, in manufacturing, metal and polymer-based 3D printing is allowing companies to produce highly customized components with intricate geometries that traditional methods cannot achieve. This technology is particularly beneficial in aerospace, automotive, and healthcare industries, where lightweight and durable parts are essential. For instance, Materialize, a leading manufacturer of industrial applications, empowers users by sharing algorithms from its Magics software, enabling manufacturers to tailor workflows for better quality, faster production, and reduced costs. Moreover, the integration of AI and advanced digital design tools is revolutionizing 3D printing workflows. AI-driven design optimization and real-time monitoring capabilities minimize material consumption and energy use while enhancing precision. All such advancements are expected to drive the growth of the domain in the coming years.

Growing use of sustainable & green building materials boosting the dynamics of the industry

The demand for sustainable and green building materials is on the rise as several players are increasingly prioritizing emerging environmental concerns. Architects and developers are actively incorporating materials like carbon-negative concrete, bamboo-based composites, recycled steel, and engineered wood to minimize the carbon footprint of buildings. Green building certification programs, such as LEED and BREEAM, are further accelerating the integration of energy-efficient and eco-friendly materials into construction projects.

Moreover, the growing emphasis on energy efficiency and smart building systems, the use of recycled and renewable materials, and water conservation techniques are expected to reshape the construction sector significantly in Q1 2025. The integration of smart technologies, such as IoT and AI is offering cutting-edge energy efficient solutions and boosting overall building performance. Construction companies are also embracing circular economy principles, with recycling and reusing materials becoming standard practices. Furthermore, innovative materials like low-carbon concrete, bio-based options, and even self-healing concrete are gaining traction. Major companies are focusing on developing innovative green cement and extruded polystyrene insulation (XPS) products to enhance energy efficiency and reduce environmental impact. These trends are further supported by regulatory initiatives and increasing consumer demand for eco-conscious buildings, offering notable growth opportunities for the sustainable construction market.

Rising emphasis on smart waste management offering lucrative opportunities Nowadays, smart waste management is becoming one of the key trends in the construction and manufacturing sector for minimizing waste, ensuring environmental compliance, and optimizing resource efficiency. The increasing use of modular construction, prefabrication, and sustainable manufacturing is driving companies to adopt smart waste solutions for tracking and reducing excess materials, recycling byproducts, and lowering carbon emissions. The smart waste management market is witnessing remarkable growth as modern technologies, like IoT sensors, help track bin fill levels, analyze data in the cloud, and improve collection efficiency. This real-time data allows for better decision-making, simplifying the waste collection and processing methods. The implementation of these modern technologies results in improved operational efficiency, reduced costs, cleaner environments, and minimized carbon footprints.

Furthermore, companies like Bin-e are designing smart waste bins that use AI to automatically sort recyclables, reducing human error and lowering waste management costs. These systems lead to significant cost reductions in waste collection and minimization of carbon emission. Additionally, construction firms are using platforms like SmartWaste to monitor and reduce environmental impacts, track carbon emissions, and ensure compliance across projects.

The essence

The construction and manufacturing sector has experienced prominent growth, attributed to rapid technological advancements such as the adoption of robotics, automation, AI, and 3D printing technology in construction processes. Moreover, the rising emphasis on green building practices has created extensive growth opportunities for the domain in the past few years. In addition, the rising focus on smart waste management by industry leaders is expected to create new avenues for the domain in the first quarter of 2025.

To gain more insights into the comprehensive analysis of the latest advancements in the construction and manufacturing sector, feel free to reach out to our industry analysts!