Table Of Contents

- Supply Side Analysis

- Electric motor production has steadily increased over the past few decades due to the rising global demand for efficient and sustainable power solutions. This growth is fueled by technological advancements, more industrial automation, and a move toward energy-efficient systems.

- Historical Growth Milestones

- Value Chain Analysis

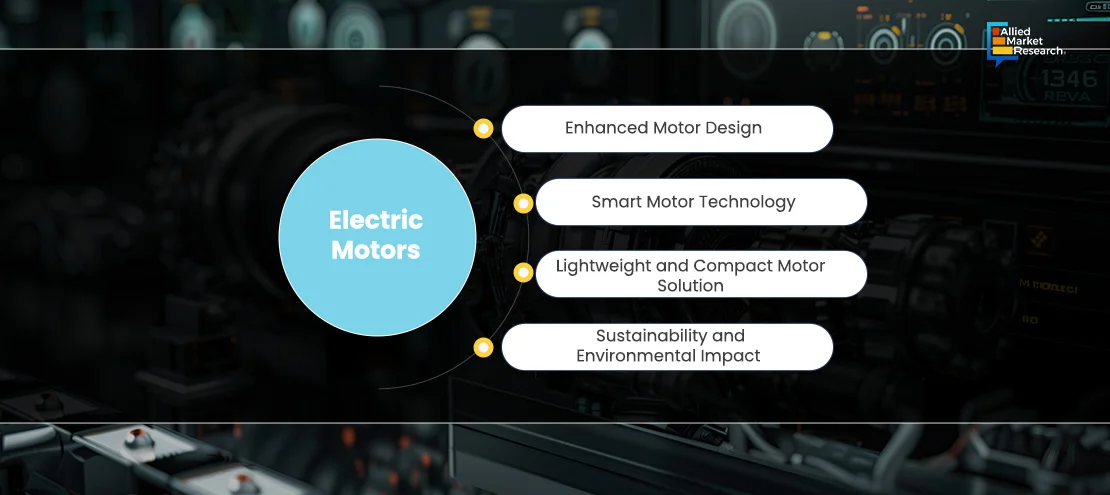

- Advanced Electric Motors and Thier ImpactEnhanced Motor Designs

- Smart Motor Technology

- Lightweight and Compact Motor Solutions

- Sustainability and Environmental Impact

- Case Studies

- Innovation at GreenTech Manufacturing

- Efficiency Gains with QuickBuild Solutions

- Sustainable Innovations at EcoHomes LLC

- The Latest Breakthroughs in Electric Motor Technology

- Conclusion

Sonia Mutreja

Koyel Ghosh

The Power of Electric Motors: Innovative Tech Driving the Future

Electric motors cover a broad spectrum of types and applications, offering efficiency, power, and versatility across various sectors. They include brushless DC motors, industrial smart motors, air motors, micro motors, and CE electric motors. They are widely used in residential, commercial, and industrial settings. In homes, electric motors are essential for appliances and HVAC systems, enhancing convenience and energy efficiency. In commercial and industrial settings, they are essential for automation, manufacturing, and running heavy machinery, prioritizing performance, reliability, and energy efficiency. Technological advancements, including smart motor technology and energy-efficient designs, boost operational efficiency and sustainability. With the rise of industrial automation and eco-friendly solutions, electric motors are set for continued innovation and growth.

The global electric motor market was valued at around $142.2 billion in 2020 and is projected to grow at a CAGR) of around 9.5% from 2023 to 2032.

Supply Side Analysis

Electric motor production has steadily increased over the past few decades due to the rising global demand for efficient and sustainable power solutions. This growth is fueled by technological advancements, more industrial automation, and a move toward energy-efficient systems.

Historical Growth Milestones

2000: In 2000, global production of electric motors reached 200 million units. This period marked the early stages of increased industrial automation and the adoption of electric motors in various sectors. The rise in production was fueled by the need for more reliable and efficient power sources in manufacturing and other industrial applications.

2010: By 2010, production had surged to 350 million units. This 75% increase over a decade was attributed to the rapid advancement in motor technologies, such as the development of brushless DC motors and energy-efficient models. The push for automation in industries like automotive, aerospace, and consumer electronics also played a significant role in this growth. Additionally, government regulations and incentives for energy-efficient technologies spurred the adoption of advanced electric motors.

2020: In 2020, global production hit 500 million units, reflecting a further 43% increase from 2010. This growth was driven by the continued expansion of industrial automation and the rise of smart motor technologies. Innovations such as IoT-enabled motors and real-time performance monitoring became more prevalent, leading to enhanced efficiency and reduced operational costs. The growing emphasis on sustainability and the need to reduce greenhouse gas emissions also accelerated the adoption of electric motors in various applications, from electric vehicles to renewable energy systems.

Value Chain Analysis

The quality of the electric motors depends on the material and components used for manufacturing them. Therefore, selection of materials and components at the initial stage of the value chain is crucial for market players. The key materials used in the manufacturing of an electric motor are copper and electrical steel.

Copper is used in windings of motor, whereas expensive materials, such as aluminum or permanent magnets, are used for specific applications of motor including electric vehicles. Moreover, some supplementary components used in electric motors include spare parts such as screw, nuts, bolts, insulating materials, and bearings. The electric steel producers are relatively few, and are concentrated in regions such as U.S., Europe, and Japan. Some of the prominent players in the industry are ATI Allegheny Ludlum, Nippon Steel, British Steel Corporation, ThyssenKrupp AG, SAC Armco, and Kawasaki Steel Corporation.

The second stage of the electric motor value chain comprises manufacturing and assembling of the components of an electric motor. Motor manufacturers assemble electric motors using the materials required for different type of motors, namely AC, DC, hermetic, and other types. In addition, an electric drive manufacturer develops techniques that are implemented in the drives and are used to transform the input current depending on the need of the motor. Several organizations, such as Siemens, ABB, Mitsubishi and Rockwell Automation, and Johnson Electric Holdings Ltd., have standardized manufacturing processes of electric motors. Therefore, supporting institutions, including government entities namely Department of Energy (DOE) and Industrial Technologies Program (ITP), that set regulations promote programs and initiatives for more efficient energy use of electric motors. Moreover, organizations such as National Electrical Manufacturers Association (NEMA), Consortium for Energy Efficiency (CEE), American Council for an Energy-Efficient Economy (ACEEE), Institute of Electrical and Electronic Engineers (IEEE), and International Electrotechnical Commission (IEC) develop standards and organize testing procedures for testing and improving the efficiency of motors.

The third stage in the value chain of electric motors comprises system integrators who assemble the motor and drive in the product. This coupling stage involves the integration of the interface of the motor with the client’s control system. The integrator segment includes equipment manufacturers, and construction & engineering companies. The fourth stage includes the industrial users of electric motors. The industrial users buy electric motors and deploy them at their production units. Some of the prominent manufacturing companies in the industry are Whirlpool, Sony, and Toyota. Further, these motors are used in a wide variety of applications such as industrial fans, compressors, pumps, lathe machines, machine tools, domestic appliances, heating ventilating & air conditioning applications, disk drives, power tools, electric cars, and automated robots.

Advanced Electric Motors and Thier Impact

Enhanced Motor Designs

Recent innovations in motor designs have significantly improved the performance of electric motors. Advanced motor types like the brushless DC motor offer high efficiency and durability. For instance, in March 2023, Nidec Corporation introduced its latest brushless DC motor, featuring advanced magnetic materials and optimized design, promising up to 30% higher efficiency compared to traditional motors. Similarly, Siemens' new range of industrial smart motors incorporates real-time monitoring and predictive maintenance features, enhancing operational efficiency and reducing downtime.

Smart Motor Technology

Smart motor technology is revolutionizing the electric motor industry. These motors are equipped with sensors and IoT connectivity, enabling real-time performance monitoring and predictive maintenance. A 2022 study by the Smart Motor Institute found that smart motors could reduce maintenance costs by up to 20%. Companies like ABB have launched products like the Ability Smart Sensor for motors, which offers comprehensive insights into motor health and performance, leading to significant efficiency gains. Additionally, Schneider Electric's Altivar Process smart motor drives integrate advanced analytics to optimize motor operation, contributing to reduced energy consumption and improved process reliability.

Lightweight and Compact Motor Solutions

The development of lightweight and compact motor solutions has made integration into various applications more efficient. These innovations reduce the overall weight and space requirements, making them ideal for modern, space-constrained environments. In April 2023, Maxon Motors introduced its new line of micro motors, which are 40% lighter than traditional motors, significantly enhancing their applicability in medical devices and robotics. Similarly, Parker Hannifin has launched their lightweight air motors, which not only reduce the load on machinery but also offer excellent performance in hazardous environments where electric motors might not be suitable.

Sustainability and Environmental Impact

Electric motors are an environmentally friendly option, contributing to sustainable industrial practices. Many modern electric motors are designed to be energy-efficient, reducing electricity consumption and greenhouse gas emissions. A 2023 report by the International Energy Agency (IEA) suggests that using energy-efficient electric motors in industrial settings could cut global electricity demand by 10%. Moreover, electric motors are highly recyclable, with many components being repurposed at the end of their lifecycle, minimizing environmental impact.

Electric motors can significantly improve energy efficiency in industrial applications. By optimizing motor design and incorporating advanced control technologies, modern motors can reduce energy consumption by up to 30%. A study by the U.S. Department of Energy in 2023 showed that industries using energy-efficient electric motors experienced a 15% reduction in operational costs.

Case Studies

Innovation at GreenTech Manufacturing

GreenTech Manufacturing, a leader in sustainable industrial solutions, has embraced energy-efficient electric motors across multiple projects to enhance operational efficiency and sustainability. By incorporating smart motor technology, GreenTech has achieved significant energy savings and reduced maintenance costs.

One notable project is the GreenFactory Initiative, completed in June 2023. This state-of-the-art facility features industrial smart motors with real-time monitoring capabilities, which substantially lowered the facility's energy consumption and maintenance needs. The smart motors utilized in the GreenFactory Initiative reduced energy consumption by 20%, translating to annual savings of approximately $1.2 million. Furthermore, the predictive maintenance features of these smart motors decreased downtime by 15%, resulting in a 10% increase in overall production efficiency.

Efficiency Gains with QuickBuild Solutions

QuickBuild Solutions, renowned for its rapid deployment structures, has integrated lightweight and compact electric motors to improve efficiency and project outcomes. These motors have significantly reduced installation times and enhanced operational efficiency.

In March 2024, QuickBuild Solutions reported a remarkable 25% increase in project completion rates due to the adoption of these advanced motor technologies. This efficiency gain allowed the company to handle more projects simultaneously, improving customer satisfaction. The lightweight motors used were 30% lighter than traditional models, reducing installation time by 20%. This reduction in installation time led to a cost saving of approximately $500,000 per project, enabling QuickBuild Solutions to increase its annual project capacity by 15%.

Sustainable Innovations at EcoHomes LLC

EcoHomes LLC, a prominent developer of eco-friendly residential communities, has leveraged electric motors to enhance the sustainability and energy efficiency of its housing projects. By utilizing energy-efficient motors, EcoHomes LLC has been able to create solutions that are not only durable but also environmentally friendly.

The GreenValley Housing Development, completed in October 2023, features electric motors made from 25% recycled materials. These energy-efficient motors contributed to a 15% reduction in energy costs for homeowners, averaging an annual saving of $300 per household. The development includes 150 homes, resulting in a total annual energy cost saving of $45,000 for the community. Moreover, the use of recycled materials in the motors reduced the development's carbon footprint by 10%, aligning with EcoHomes LLC's commitment to sustainability. The electric motors also demonstrated exceptional durability, with a projected lifespan of 20 years and minimal maintenance requirements, further enhancing their environmental and economic benefits.

The Latest Breakthroughs in Electric Motor Technology

Innovations in electric motors such as 3D printing and robotic assembly are reshaping the industry, allowing companies to produce components with higher precision and streamline manufacturing processes. For example, Tesla is utilizing 3D printing technology to create intricate motor components, while GE's development of a robotic assembly line aims to reduce manufacturing costs by 20%.

Emerging markets in Asia-Pacific and Latin America are fueling the demand for electric motors, driven by rapid urbanization and industrialization. In 2023, China represented 28% of global motor production, significantly increasing the need for efficient motor solutions. Similarly, India's industrial sector is growing at an annual rate of 8%, driving the need for advanced motor technologies. Siemens' expansion in Brazil reflects efforts to meet the growing demand in Latin America, where the industrial sector is projected to grow by 3.9% annually from 2022 to 2027.

The growing focus on energy efficiency and sustainability is driving the global adoption of electric motors. Green building certifications like LEED are shaping purchasing decisions, leading many new industrial projects to choose electric motors for their environmental advantages. According to a survey by the Green Building Council, in 2023, 60% of new industrial buildings in the U.S. were LEED certified, with electric motors being a preferred choice for 45% of these projects.

Conclusion

The landscape of electric motor is booming with new technologies and a focus on sustainability. Innovations in motor design, smart technology, and lightweight options are driving this growth. Electric motors have become more durable, efficient, and eco-friendly, making them perfect for a variety of uses. With these advancements, the industry is ready to meet modern demands and support a sustainable future.

Allied Market Research is a reliable partner for vendors in the electric motor industry, offering detailed insights and customized strategies to enhance motor technologies across various sectors. These sectors include residential buildings, commercial enterprises, public infrastructure, educational institutions, and industrial applications. With AMR's expertise, businesses can identify opportunities, assess market demand, and foster innovation in electric motor solutions. This enables companies to boost performance, improve energy efficiency, and maintain competitiveness in an evolving market.

For more details about technologies, innovations, and dynamics in the electric motor industry, contact our specialists today!